Hydraulic cutting and gas explosion combined enhancing extraction method for fracturing coal body in drill hole

A technology for hydraulic slitting and gas explosion, which is applied in the directions of gas discharge, earth-moving drilling, and fluid extraction, etc., can solve the problem of limited effective influence range of a single slit drilling hole, expand the effective pressure relief influence range, and reduce gas adsorption. Potential, the effect of promoting gas desorption and flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

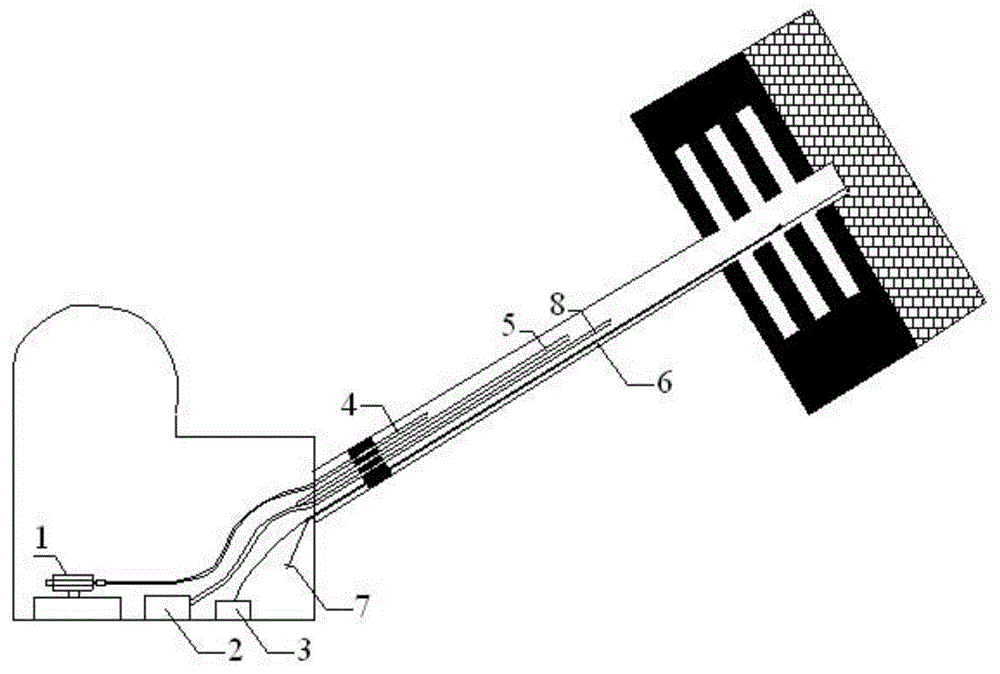

[0022] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0023] Such as figure 1 As shown, the specific steps of the method are as follows:

[0024] (1) In the coal seam, the hole positions of the drainage holes and the explosion holes are alternately arranged; wherein, the distance between the extraction holes and the centers of the explosion holes is 15-20m;

[0025] (2) Construction of drainage holes, sealing of holes, and connection to the gas drainage pipe network for gas drainage;

[0026] (3) Use a drilling rig to drill into the hole position of the explosion hole to 1m through the roof of the coal seam, and then withdraw the drill; use a high-pressure jet to cut the coal body around the explosion hole to form several slots;

[0027] (4) Bind the wire of the ignition device 3 on the detection tube 6, and then send the detection tube 6 into the bottom of the explosion hole, so that the front end of the wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com