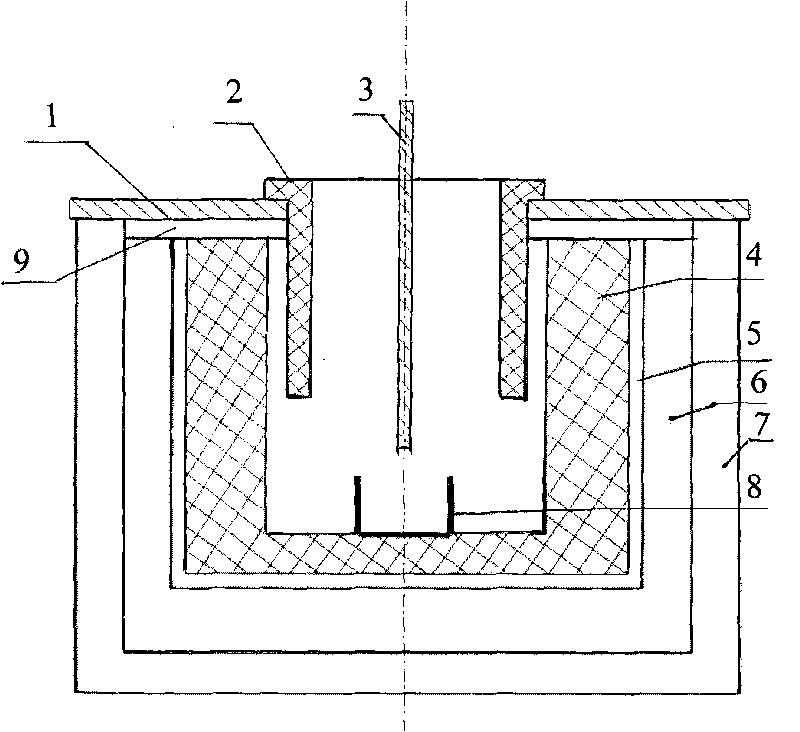

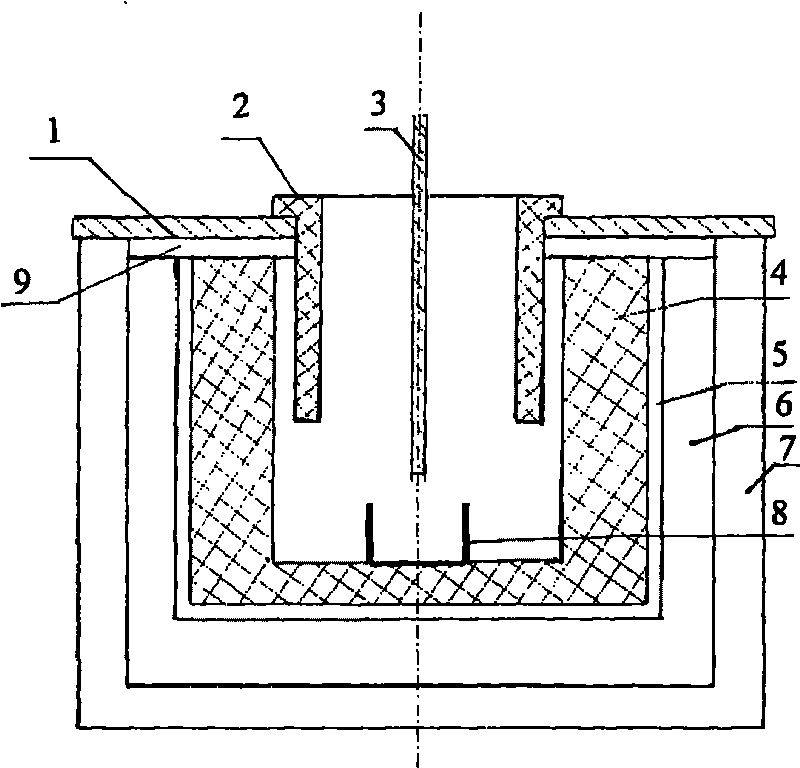

Rare earth aluminum alloy, and method and device for preparing same

An aluminum alloy and rare earth metal technology, applied in the field of rare earth aluminum alloy and its preparation, can solve the problems of high production cost and risk, difficulty in controlling rare earth content, low rare earth content, etc., so as to reduce the consumption of auxiliary materials, improve the metal yield and Current efficiency and product quality, the effect of stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

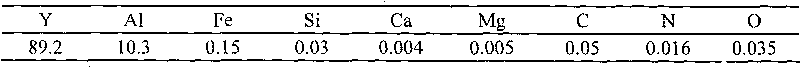

[0048] Φ450mm circular graphite electrolytic cell is used, the anode is composed of 4 graphite plates, the tungsten cathode is Φ55mm, and the electrolyte ratio is YF 3 : nNaF AlF 3 : LiF=80:15:5, n=3, the proportion of raw materials added is Y 2 o 3 : Al 2 o 3 =86:14, the electrolysis temperature is 1000-1050°C, the current intensity is 2400A, and the anode current density is 0.5-0.8A / cm 2 , the cathode current density is 5~6A / cm 2 , electrolysis time 1 hour, the mixture addition is 2.5Kg, obtains alloy 2.05Kg, yttrium content 89.2% in the alloy, current efficiency is 74.5%, metal yttrium yield 90.1%, alloy composition is shown in Table 1.

[0049] Table 1 Alloy Composition Analysis Results / %

[0050]

Embodiment 2

[0052] Φ450mm circular graphite electrolytic cell is used, the anode is composed of 6 graphite plates, the tungsten cathode is Φ30mm, and the electrolyte ratio is YF 3 : nNaF AlF 3 : LiF=90:5:5, n=2.5, the proportion of raw materials added is Y 2 o 3 : Al 2 o 3 =94:6, the electrolysis temperature is 1050-1100°C, the current intensity is 2800A, and the anode current density is 1-1.5A / cm 2 , the cathode current density is 9~10A / cm 2 , electrolysis time 1 hour, the mixture addition is 3.1Kg, obtains alloy 2.2Kg, yttrium content 96.3% in the alloy, current efficiency is 74.2%, metal yttrium yield 92.4%, alloy composition is shown in Table 2.

[0053] Table 2 Alloy Composition Analysis Results / %

[0054]

Embodiment 3

[0056] Φ450mm circular graphite electrolytic cell is used, the anode is composed of 4 graphite plates, the tungsten cathode is Φ45mm, and the electrolyte ratio is ScF 3 : nNaF AlF 3 : LiF=70:20:10, n=2.5, the ratio of raw materials added is Sc 2 o 3 : Al 2 o 3 =89:11, the electrolysis temperature is 1000-1050°C, the current intensity is 2300A, and the anode current density is 0.8-1A / cm 2 , the cathode current density is 6~7A / cm 2 , electrolysis time 1 hour, the mixture addition is 1.55Kg, obtains alloy 0.92Kg, scandium content 93.8% in the alloy, current efficiency is 72%, metal scandium yield 95.9%, alloy composition is shown in Table 3.

[0057] Table 2 Alloy Composition Analysis Results / %

[0058]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Current density | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com