Composite oxidant SCR (Selective Catalytic Reduction) denitrating catalyst, preparation method and applications thereof

A technology of composite oxides and catalysts, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem of reducing catalyst activity and life, corroding pipeline equipment, increasing Operating costs and other issues, to achieve the effect of cost reduction, low cost, strong resistance to sulfur poisoning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028](1) Catalyst preparation

[0029] First, 6.0g citric acid (C 6 h 8 o 7 ) was dissolved in 30mL 30℃ deionized water; 6.08g ferric nitrate nonahydrate (Fe(NO 3 ) 3 9H 2 O) and 4.67g nickel nitrate hexahydrate (Ni(NO 3 ) 2 ·6H 2 O) (as Fe 2 o 3 and NiO account for 12.0wt% of the total catalyst content), fully stirred for 1h to obtain a mixed metal salt solution; 44.65g titanium tetrachloride (TiCl 4 ) was slowly added to the mixed metal salt solution (with TiO 2 accounted for 88.0wt% of the total catalyst content), stirred for 2 hours, dried at 100°C for 36 hours, and the obtained solid was calcined at 750°C for 5 hours under air conditions, then pressed into tablets and ground to make 40-80 mesh particles to obtain Composite oxide SCR denitrification catalyst for boiler medium temperature flue gas, spare.

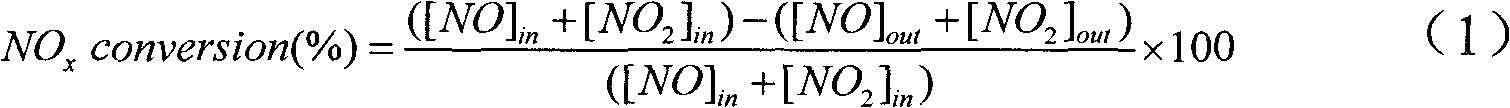

[0030] (2) Catalyst evaluation

[0031] Put the catalyst obtained above into a stainless steel reaction tube, and use a programmed temperature controller t...

Embodiment 2

[0035] (1) Catalyst preparation

[0036] First, 8.1g oxalic acid (C 2 h 2 o 4 2H 2 O) was dissolved in 40 mL of 70°C deionized water; 3.64 g of copper nitrate trihydrate (Cu(NO 3 ) 2 ·3H 2 O) and 4.23g manganese acetate tetrahydrate (Mn(CH 3 COO) 2 4H 2 O) (with CuO and MnO 2 Accounting for 13.5wt% of the total catalyst content), fully stirred for 1h to obtain a mixed metal salt solution; 73.72g tetrabutyl titanate (Ti(OC 4 h 9 ) 4 ) was slowly added to the mixed metal salt solution (with TiO 2 accounted for 86.5wt% of the total catalyst content), stirred for 3 hours, dried at 120°C for 24h, and the obtained solid was calcined at 700°C for 6h under air conditions, then pressed into tablets and ground to form 40-80 mesh particles to obtain Composite oxide SCR denitrification catalyst for boiler medium temperature flue gas, spare.

[0037] (2) Catalyst evaluation

[0038] The catalyst evaluation process is as in Example 1.

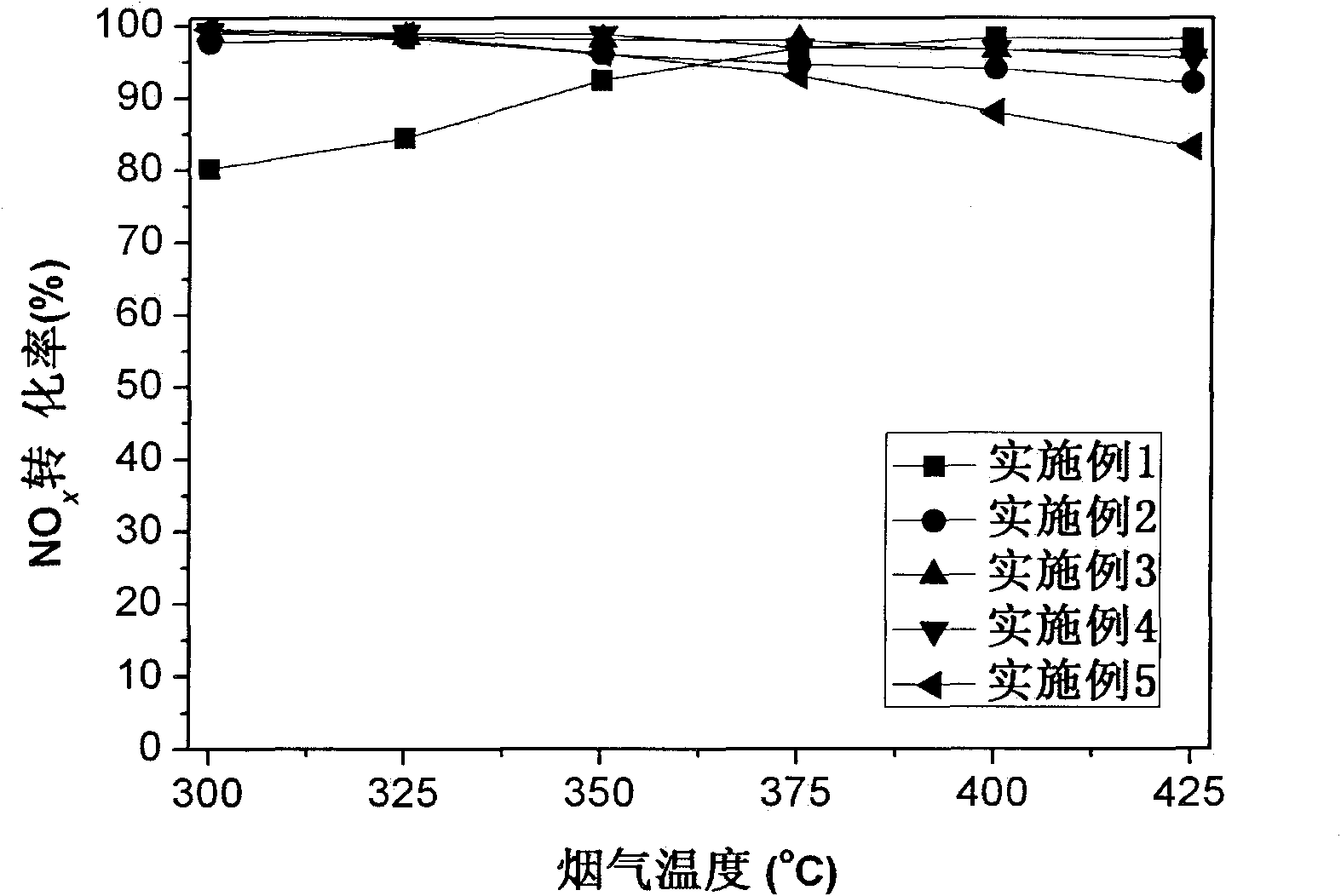

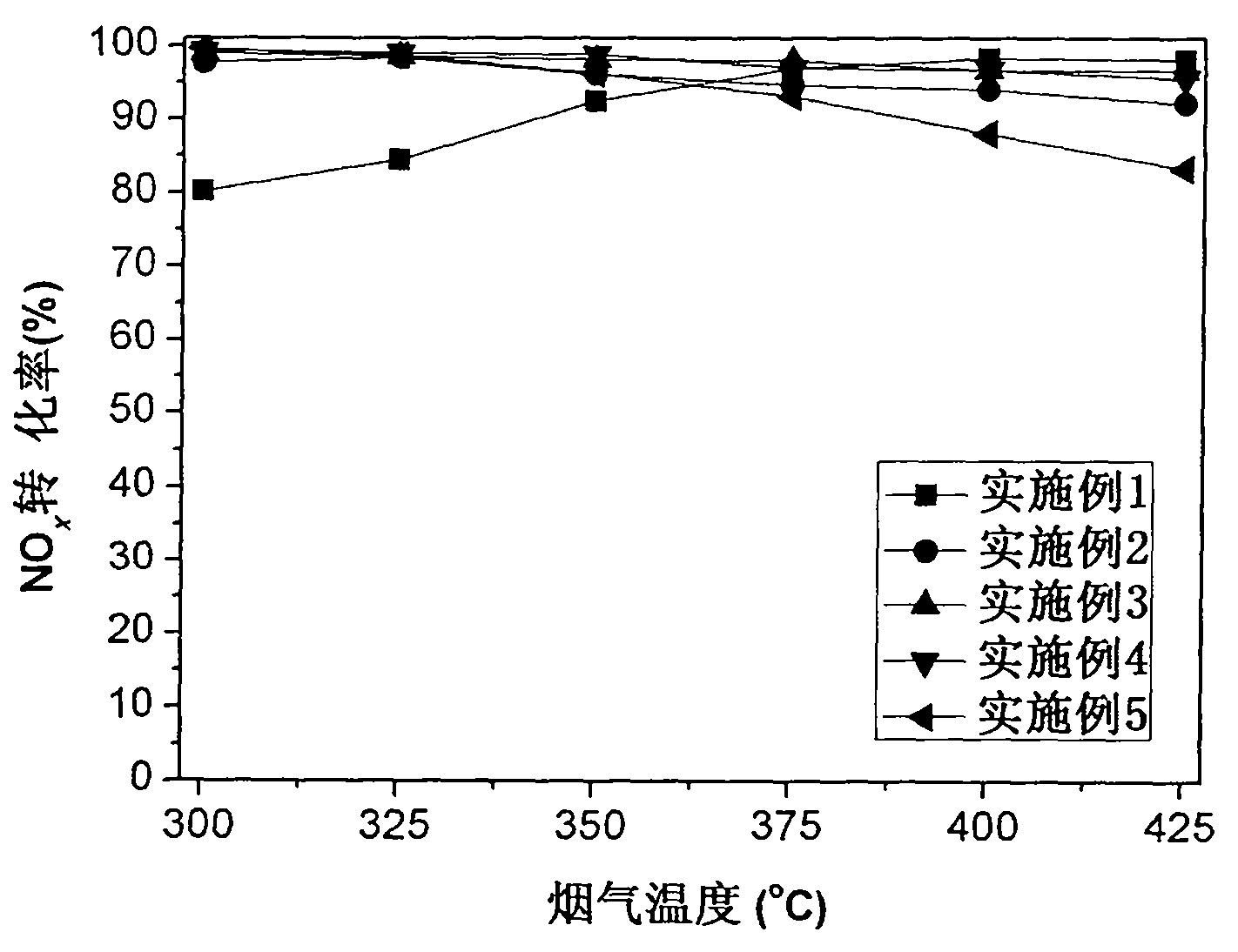

[0039] Catalyst evaluation results suc...

Embodiment 3

[0041] (1) Catalyst preparation

[0042] First, 9.0g citric acid (C 6 h 8 o 7 ) was dissolved in 40mL of 50°C deionized water; 5.06g of iron nitrate nonahydrate (Fe(NO 3 ) 3 9H 2 O), 2.43g copper nitrate trihydrate (Cu(NO 3 ) 2 ·3H 2 O) and 2.82g manganese acetate tetrahydrate (Mn(CH 3 COO) 2 4H 2 O) (as Fe 2 o 3 , CuO and MnO 2 Accounting for 14.0wt% of the total catalyst content), fully stirred for 1.5h to obtain mixed metal salt solution; 40.85g titanium tetrachloride (TiCl 4 ) was slowly added to the mixed metal salt solution (accounting for 86.0wt% of the total catalyst content), stirred for 4 hours, dried at 160°C for 12 hours, and the obtained solid was calcined at 550°C for 8 hours under air conditions, then pressed into tablets and ground to produce 40-80 mesh particles to obtain a composite oxide SCR denitrification catalyst for boiler medium-temperature flue gas, which is ready for use.

[0043] (2) Catalyst evaluation

[0044] The catalyst evaluatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com