Manufacture technique for thermonuclear reactor flow-passage containing parts

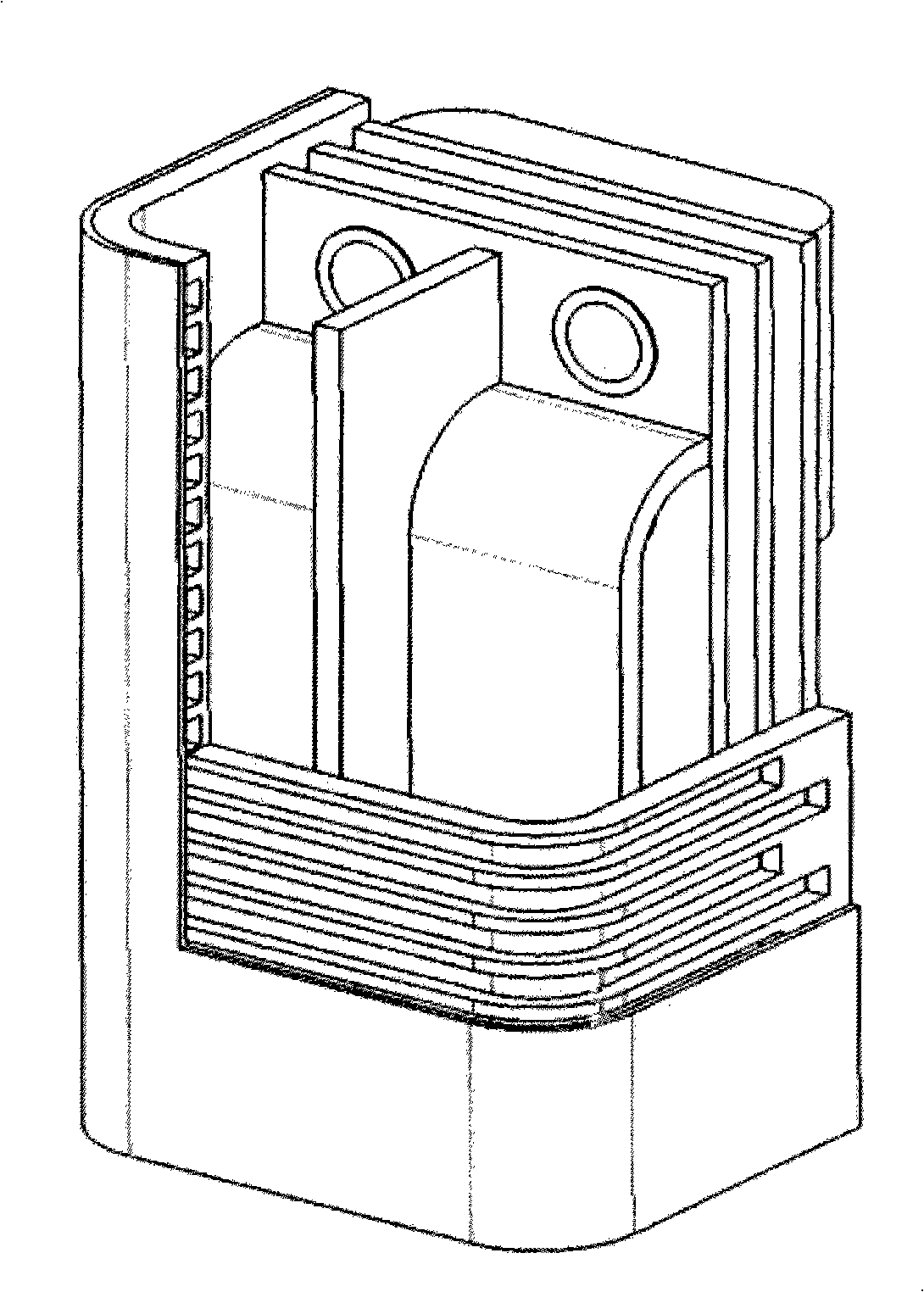

A flow channel component and manufacturing process technology, applied in the field of manufacturing process applicable to fusion reactor cladding containing flow channel components, can solve the problems of long weld seam of the first wall, complex structure, difficult to meet the operation requirements of the first wall, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Now take the processing and manufacturing of the first wall of the cladding of China's liquid lithium-lead fusion reactor as an example for further explanation.

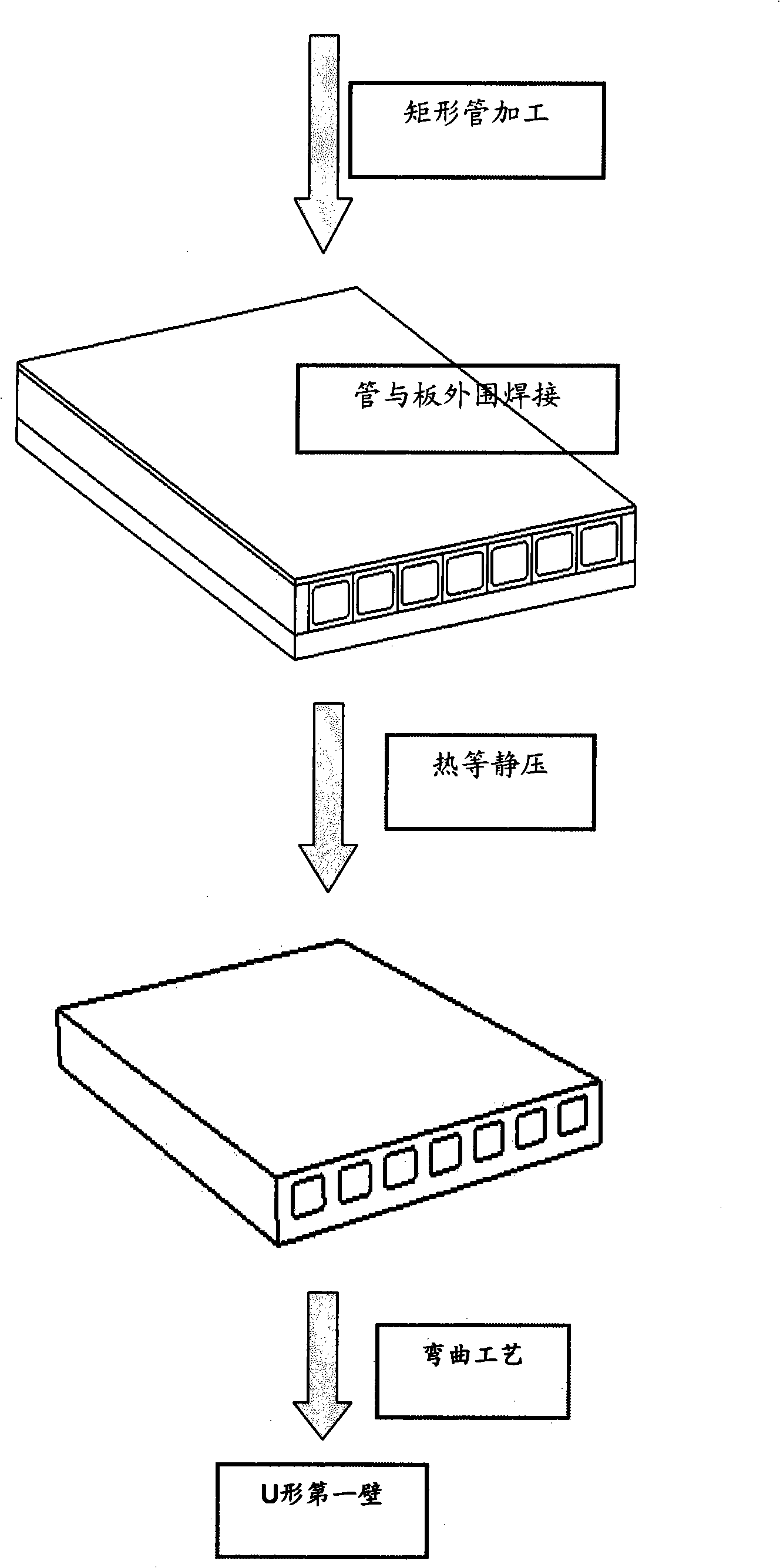

[0020] China's liquid lithium-lead fusion reactor cladding design uses Chinese low-activation martensitic steel (CLAM) steel as the structural material. The specific manufacturing steps are as figure 2 , and detailed as follows:

[0021] 1) Manufacture CLAM steel plates and rectangular pipes, and use grinding machines or milling machines for precision surface processing, and the surface roughness can reach Ra<6.3μm;

[0022] 2) Ultrasonic cleaning of CLAM steel plates and rectangular pipes (the solution is a mixture of acetone and alcohol) for decontamination;

[0023] 3) Carry out vacuum degassing treatment at 300-1000°C, and the vacuum degree is required to be below 1Pa to remove the H adsorbed on the surface of CLAM and absorbed and stored on the surface 2 O, O 2 After treatment, store them in a clean,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com