Production process of high-cleanliness non-quenched and tempered plastic mold thick steel plate

A technology of plastic mold steel and production process, which is applied in the field of plastic mold steel, and can solve the problems of preventing central segregation, porosity, shrinkage cavity, insufficient ability to remove inclusions, insufficient lamination ability of loose holes in the center of billets and internal cracks, and single pass Sub-reduction rate, small cumulative reduction rate, etc., to achieve the effect of less inclusions, good mechanical properties, and clean and dense interior

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with embodiment the present invention is further described.

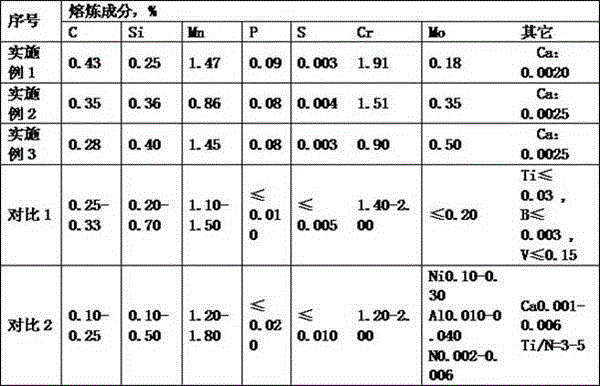

[0035] A high-clean non-quenched and tempered plastic mold steel thick plate, its chemical composition and mass percentage are: carbon 0.25-0.45%, silicon 0.20-0.50%, manganese 0.70-1.50%, chromium 0.70-2.00%, molybdenum 0.15-0.55% %, phosphorus <0.01%, sulfur <0.005%, calcium 0.0010-0.0030%, and the rest are iron and unavoidable impurities.

[0036] The above chemical composition design is simple, through the C~Mn~Cr~Mo alloying technology, the content of Mn and Cr is increased, and a certain amount of Mo is added to inhibit the transformation of austenite to ferrite and pearlite, so that the steel has a high Excellent hardenability, obtain bainite structure, do not add Ti and V elements that are easy to generate inclusions, and it is easy to obtain cleaner steel.

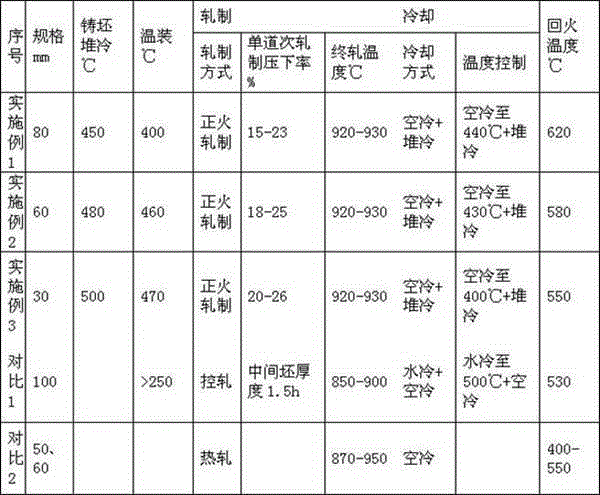

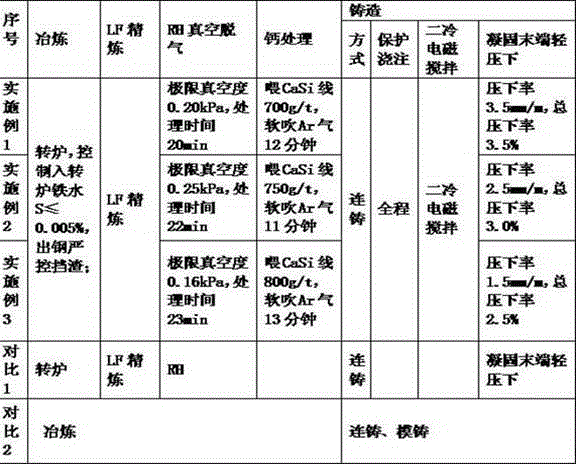

[0037] The production process of the above-mentioned high-clean non-quenched and tempered plastic mold steel plate, its step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com