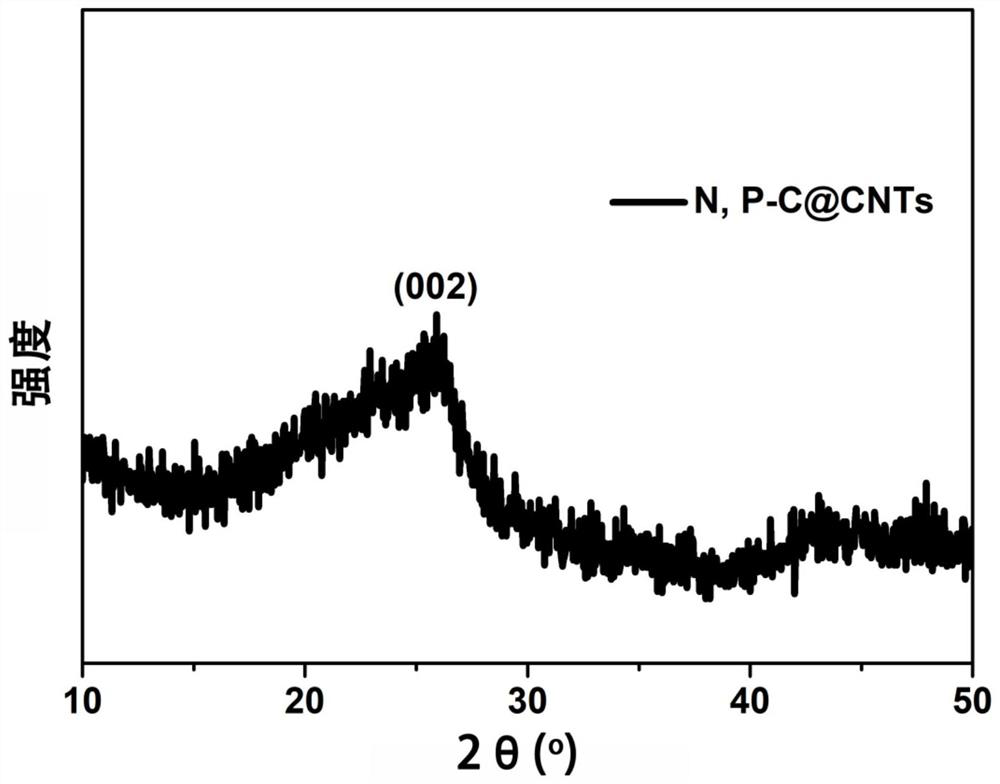

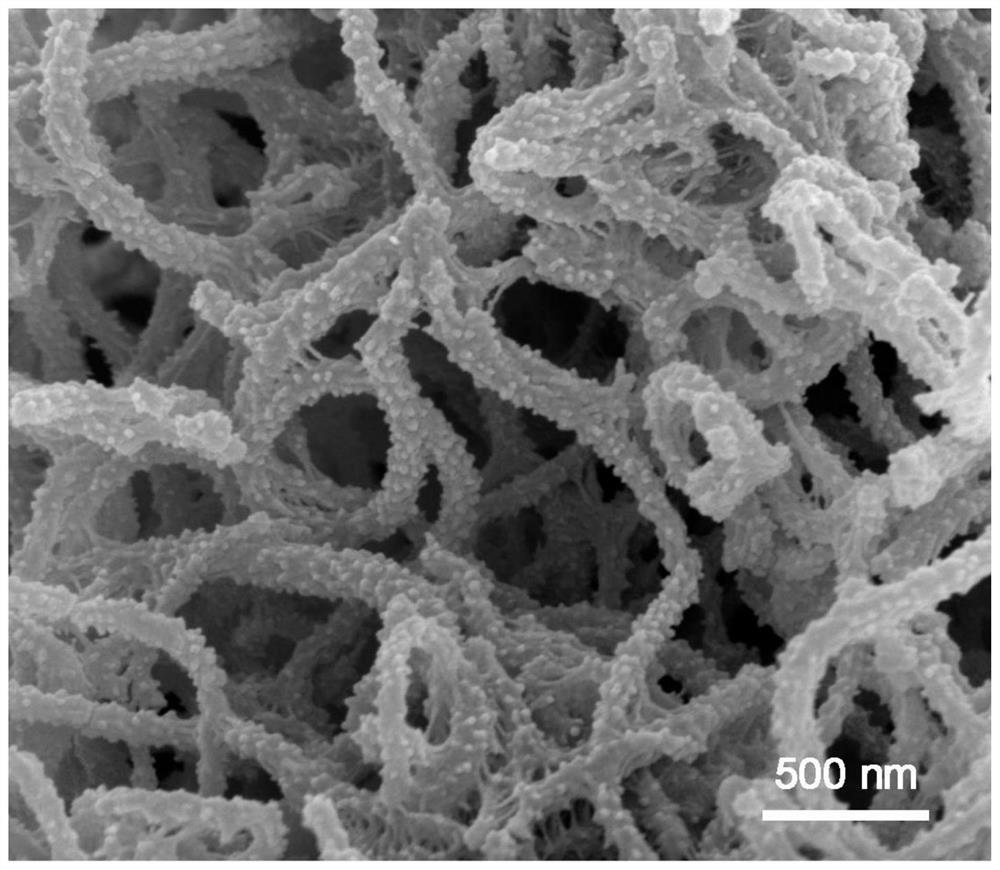

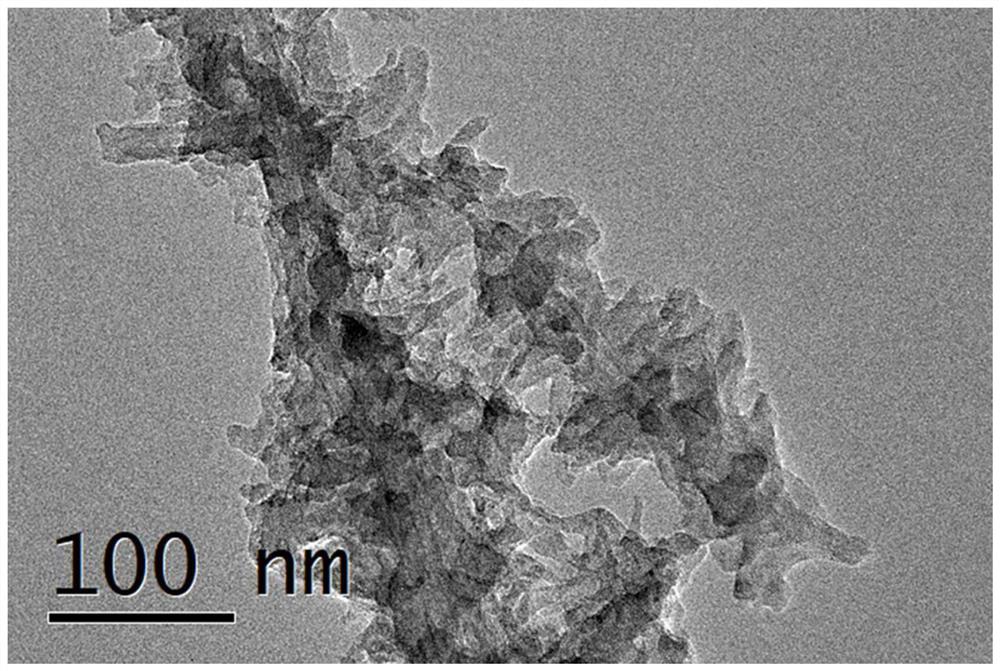

A large-scale production method of nitrogen-rich and phosphorus-doped amorphous carbon/graphite carbon nanocomposite powder

A nanocomposite, amorphous carbon technology, applied in the direction of carbon compounds, multi-walled carbon nanotubes, nanocarbons, etc., can solve the problem of amorphous carbon's low content of heteroatom doping, low preparation purity, and difficulty in large-scale preparation and other problems, to avoid environmental conversion problems, high purity, and achieve high-efficiency production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] 1. Distill the aniline monomer (purity ≥ 99%, water content < 0.1%) under reduced pressure, during which nitrogen gas is continuously introduced to protect against the oxidation of aniline, and an oil bath (glycerol, glycerol) is used after decompression , heated to 100°C, treated for 0.5 hours, sealed and protected from light after distillation, and stored in the refrigerator for cooling;

[0050] 2. Multi-walled carbon nanotubes (2g, purity ≥ 95%) are put into a mixed solution containing concentrated sulfuric acid and concentrated nitric acid (the volume ratio of concentrated sulfuric acid and concentrated nitric acid is 4:1 (40ml, the mass fraction of concentrated sulfuric acid ≥ 70%; the mass fraction of concentrated nitric acid is about 68%), heated to 130°C, and the heating rate was 0.5°C / min for oil bath heating for 2.5 hours. Stirring speed is 500 rev / min);

[0051] 3. Add 40 mg of acidified CNTs / graphene oxide (purity ≥ 95%) to 200 ml of deionized water, ultra...

Embodiment 2

[0058] 1. Distill the aniline monomer (purity ≥ 99%, water content < 0.1%) under reduced pressure, during which nitrogen gas is continuously introduced to protect against the oxidation of aniline, and an oil bath (glycerol, glycerol) is used after decompression , heated to 130°C, treated for 0.2 hours, sealed and protected from light after distillation, and stored in the refrigerator for cooling;

[0059] 2. Multi-walled carbon nanotubes (2g, purity ≥ 95%) are put into a mixed solution containing concentrated sulfuric acid and concentrated nitric acid (the volume ratio of concentrated sulfuric acid and concentrated nitric acid is 4:1 (40ml, the mass fraction of concentrated sulfuric acid ≥ 70%; concentrated nitric acid mass fraction is about 68%), be heated to 160 ℃, and heating rate is 1 ℃ / min to carry out oil bath heating 1.5 hours, in this process, this high-temperature solution is condensed and refluxed and constantly stirred (continuous stirring Stirring speed is 500 rev / ...

Embodiment 3

[0067] 1. Distill the aniline monomer (purity ≥ 99%, water content < 0.1%) under reduced pressure, during which nitrogen gas is continuously introduced to protect against the oxidation of aniline, and an oil bath (glycerol, glycerol) is used after decompression , heated to 110°C, treated for 0.3 hours, sealed and protected from light after distillation, and stored in the refrigerator for cooling;

[0068] 2. Multi-walled carbon nanotubes (2g, purity ≥ 95%) are put into a mixed solution containing concentrated sulfuric acid and concentrated nitric acid (the volume ratio of concentrated sulfuric acid and concentrated nitric acid is 4:1 (40ml, the mass fraction of concentrated sulfuric acid ≥ 70%; concentrated nitric acid mass fraction is about 68%), be heated to 140 ℃, and heating rate is 0.8 ℃ / min and carries out oil bath heating 2 hours, in this process, this high-temperature solution is condensed and refluxed and constantly stirred (continuous stirring Stirring speed is 500 r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com