Device and method for testing mechanical integrity of high-temperature high-pressure well cementation cement sheath

A high temperature and high pressure, cementing technology, applied in construction and other directions, can solve the problems of rarely considering the stress impact of cement sheath, and not realizing the quantitative evaluation of cement sheath mechanics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

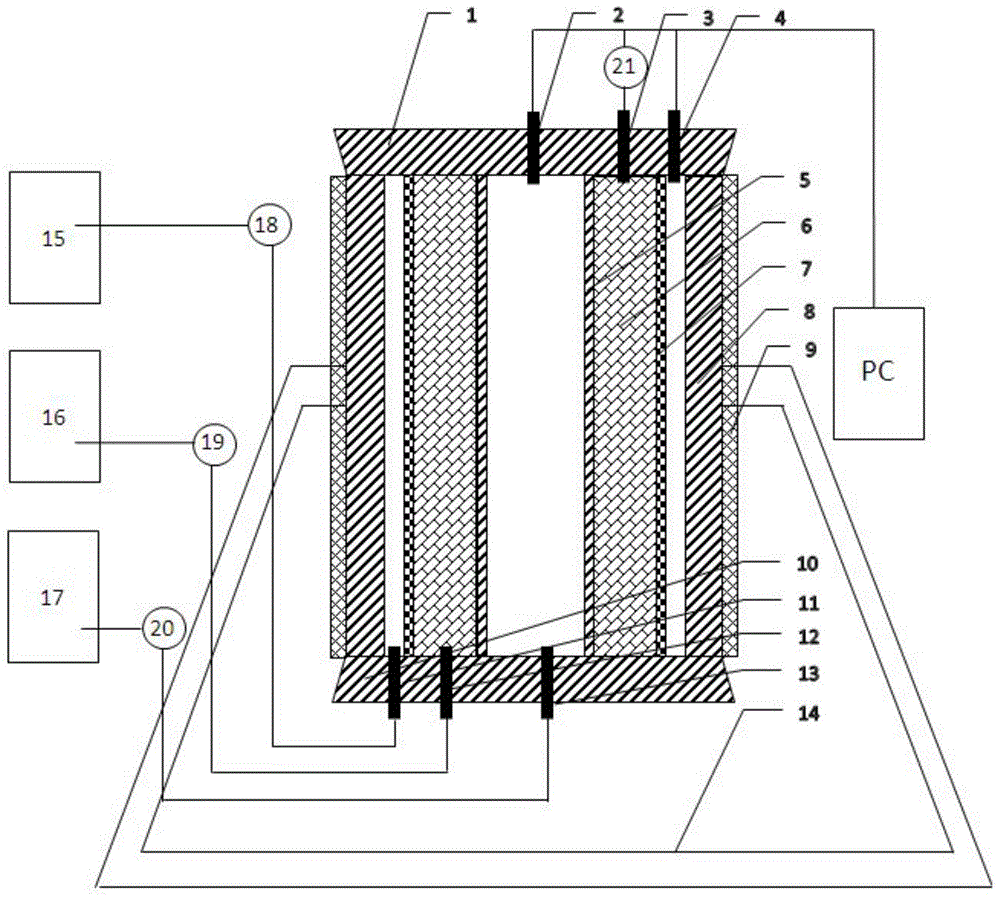

[0034] The present invention will be further described below in conjunction with accompanying drawing.

[0035] see figure 1 .

[0036] A high-temperature and high-pressure well cementing cement sheath mechanical integrity testing device includes a cement sheath curing mold and a testing work platform.

[0037] The cement sheath maintenance mold is composed of left and right molds and internal pressure sleeves. The left and right molds form a hollow cylinder with a circular interior and a square exterior. The internal pressure sleeve is located in the hollow cylinder, and the internal pressure The annular space formed by the sleeve pipe and the hollow cylinder is filled with cement slurry, and its upper and lower ends are sealed.

[0038]The test working platform includes a test body and a support. The test body is located on the support 14. There are upper plugs 1 and lower plugs 10 at the upper and lower ends respectively. The test body is mainly composed of an internal pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com