Method for Hydrolyzing and Recycling Monomers of Aromatic Polyester Composite Materials

A technology of aromatic polyester and composite materials, applied in chemical instruments and methods, preparation of organic compounds, preparation of oxygen-containing compounds, etc., can solve problems such as complex components, achieve simple and easy operation of equipment, strong practical value, The effect of mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

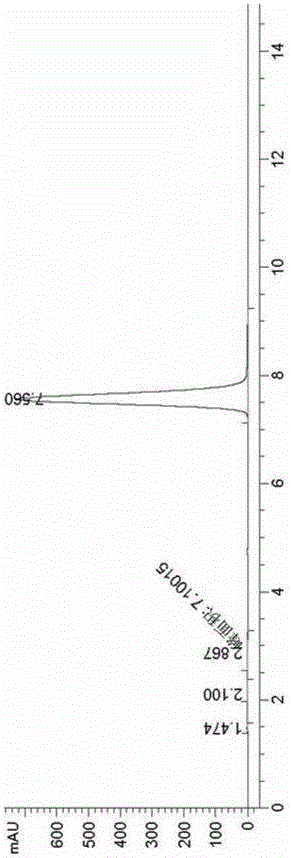

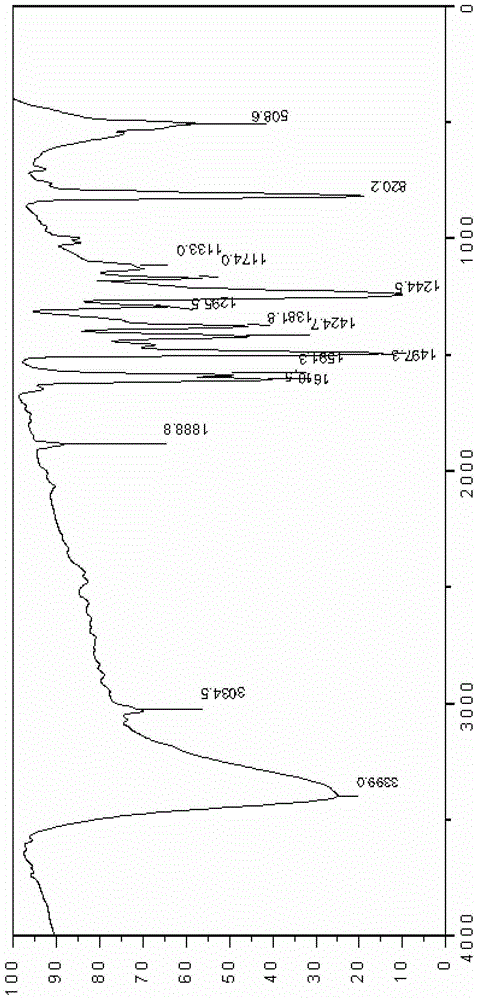

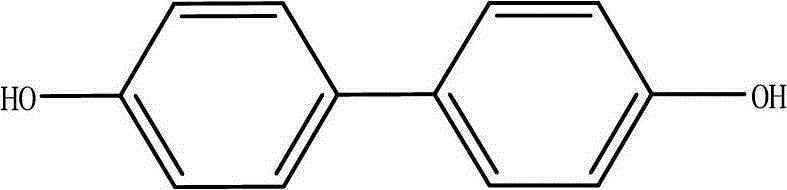

Image

Examples

Embodiment 1

[0039] 1) the aromatic polyester sheet with a glass fiber content of 29.07wt% is cut into pieces smaller than 4.5mm;

[0040] 2) Add 250g of the above-mentioned fragment raw materials into the reaction kettle, rinse with 500g of water, and blow dry with air.

[0041] 3) Put the above-mentioned treated fragments into a 3L reactor, inject 1000g of 1,4-dioxane, then add 525g of NaOH aqueous solution with a concentration of 29wt% under stirring conditions, heat to 100°C, and hydrolyze under stirring conditions for 10h.

[0042] 4) The above hydrolyzate mixture was placed in a rotary evaporator to evaporate 1,4-dioxane under reduced pressure, and the obtained solid intermediate product was off-white. 1600 g of water was added, the pH value of the solution was 13.8, and the filtrate was collected by filtration.

[0043] 5) The concentration of 0.8mol / l HCl aqueous solution was added to the filtrate to adjust the pH, and the pH value of the solution was controlled to be 9.0, and a w...

Embodiment 2

[0048] The charging amount of raw material, reaction condition are as example 1, and difference is to replace dioxane with methanol, and the hydrolysis reaction temperature is 66 ℃, and the HCl aqueous solution of concentration 1.2mol / l is added in the primary filtrate to control the solution pH value to be 8.1, obtains White crude biphenol 56g.

[0049] The pH value of the secondary filtrate was controlled to 2.5 with 1.2 mol / l HCl solution to obtain 70 g of a mixture of terephthalic acid and p-hydroxybenzoic acid.

[0050] Recrystallized three times with methanol to obtain 45 g of white needle-like diphenol with a purity of 99.5 wt%.

[0051] The total yield of monomer crude product after decomposition and separation was 71.1wt%.

Embodiment 3

[0053] 1) Adopt the same glass fiber-reinforced aromatic polyester chips as in Example 1, soak 1000g of the chips in 1.5L of water for 30min, rinse with 0.5L of water after filtering out the water, then add it to 2000g of a 0.2mol / l caustic soda aqueous solution at room temperature Soak for 60min, filter out the lye, rinse with 0.5L water, and then blow dry with air.

[0054] 2) Take 270g of the above-mentioned cleaned fragments, put them into a 3L reaction kettle, inject 900g of 1,4-dioxane, and then add 450g of NaOH aqueous solution with a concentration of 33wt% under stirring conditions, heat to 95°C, under stirring conditions Hydrolysis reaction 12h.

[0055] 3) The hydrolyzate mixture was placed in a rotary evaporator to evaporate 1,4-dioxane under reduced pressure, 1600 g of water was added, the pH of the solution was greater than 13, and filtered while it was hot to obtain a primary filtrate.

[0056] 4) Add 1.0 mol / l HCl aqueous solution to the filtrate to adjust the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com