Method for micro-arc oxidation in cold plate air duct

A micro-arc oxidation and air duct internal technology, which is applied in anodic oxidation, coating, surface reaction electrolytic coating, etc., can solve the problem of unfavorable density of micro-arc oxidation film layer, uneven distribution of power lines, ablation of parts edge, etc. problem, to achieve the effect of solving the ultra-narrow gap power line shielding problem, accelerating the pulse voltage response, and reducing the dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

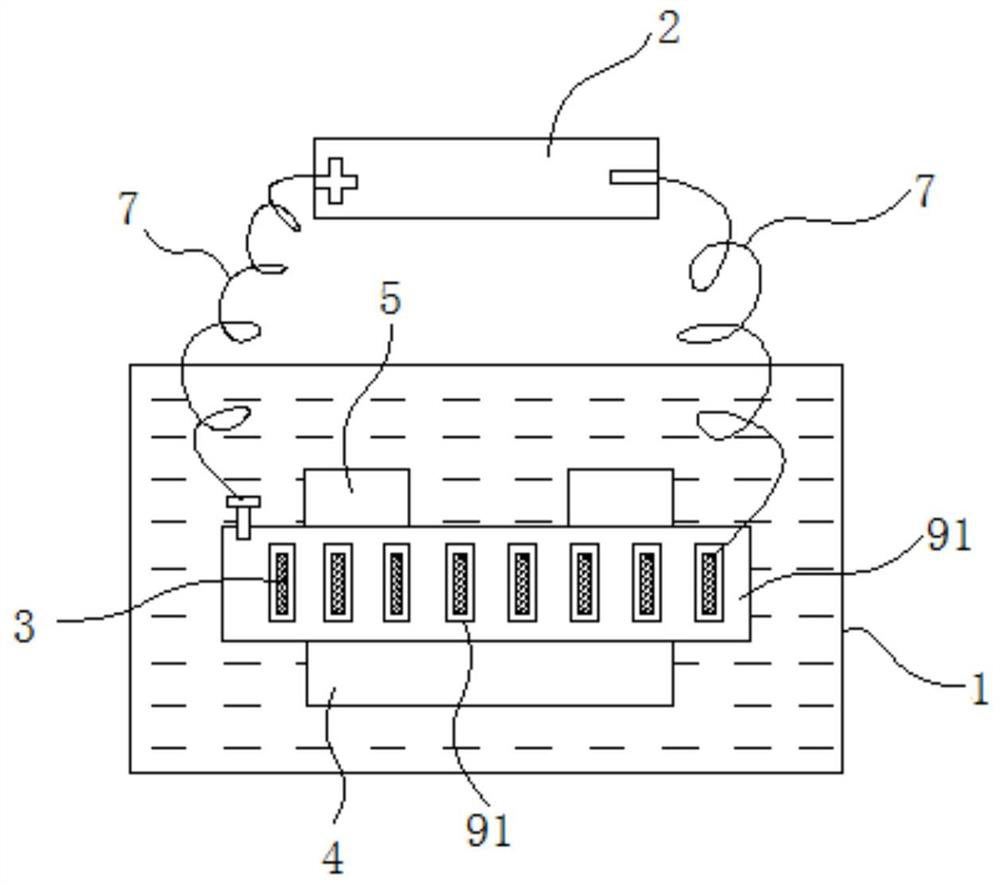

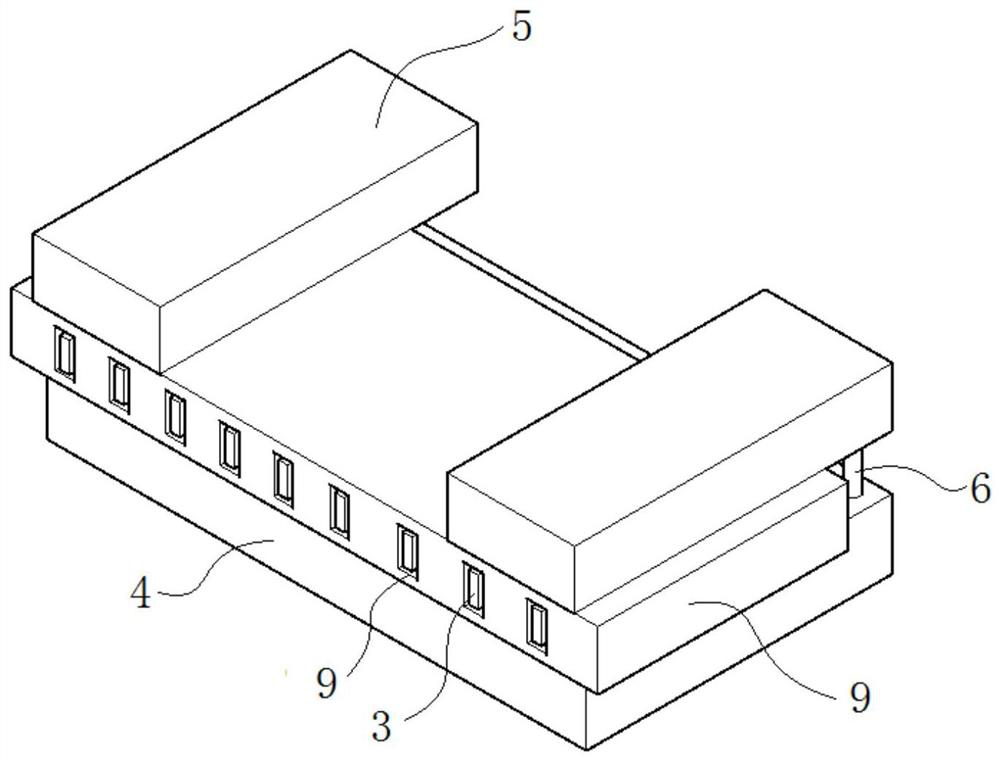

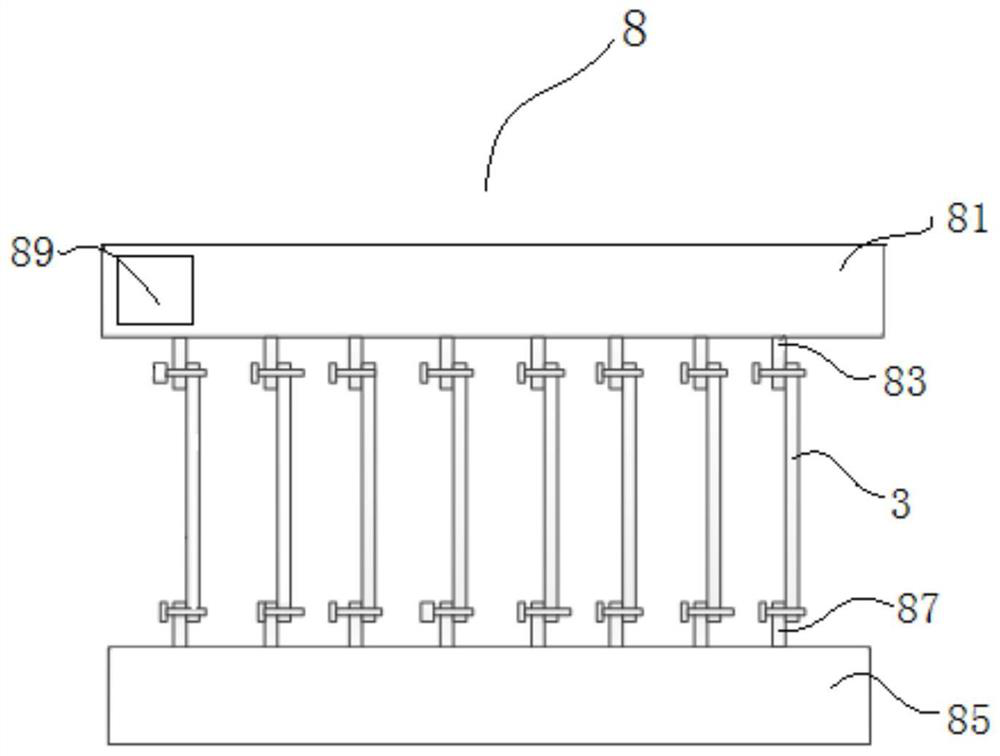

[0051] The micro-arc oxidation frock that the present invention adopts, as Figure 1-Figure 5 As shown, it includes an electrolytic cell 1 , a power supply 2 , an auxiliary cathode 3 , a bottom plate 4 , a fixing plate 5 and an auxiliary device 8 .

[0052] Such as figure 1 As shown, electrolytic solution is housed in the electrolytic cell 1, and the shape of the electrolytic cell 1 is set according to actual needs. The whole frock and the cold plate 9 are all submerged in the electrolyte, and the material of the cold plate 9 is aluminum alloy but not limited to aluminum alloy.

[0053] Such as figure 1 with figure 2 As shown, there is a space for pressing the cold plate 9 between the top wall of the bottom plate 4 and the bottom wall of the fixed plate 5, and for fixing the bottom plate 4 and the fixed plate 5, a fixed column 6 is provided between the bottom plate 4 and the fixed plate 5. In this implementation The fixing column 6 is a bolt or a screw in the example. Th...

Embodiment 2

[0066] An aluminum alloy cold plate part has 33 zigzag grooves with a length of 10 mm, a width of 5 mm and a depth of 200 mm, which is a typical large-area ultra-narrow gap micro-arc oxidation film preparation. It is difficult to prepare a uniform and stable oxide film layer by traditional micro-arc oxidation process . Adopt the micro-arc oxidation frock in embodiment 1 to carry out micro-arc oxidation, specifically comprise the following steps:

[0067] (1) cleaning

[0068] Using 3% aqueous solution of soda ash, the temperature is heated to 60 ° C, and then in HNO 3 (mass concentration 30%)+HF (mass concentration 5%) solution for brightening, and finally wash in hot water and dry in an oven for use. Carefully check whether there is water stain on the welding surface of the parts, if there is, be sure to clean it with alcohol or acetone.

[0069] (2) Partial protection

[0070] In non-MAO areas, spray paint stripper and cure at room temperature.

[0071] (3) Preparation ...

Embodiment 3

[0085] The difference between this embodiment and embodiment 2 is:

[0086] (1) The electrolyte includes sodium silicate 5g / L, sodium tungstate 5g / L, potassium hydroxide 1g / L, potassium fluoride 1g / L, and the rest is plasma water.

[0087] (2) The power supply parameters are as follows: The first stage: positive triangle wave. Voltage 320V, frequency 85HZ, oxidation time 1min; second stage: (a) positive pulse, voltage 410V, frequency 220HZ, oxidation time 20min, micro-arc oxidation solution temperature 18C; (b) negative pulse, voltage 126V, frequency 160HZ , oxidation time 15min, micro-arc oxidation solution temperature 20C.

[0088] Using the micro-arc oxidation tooling in Example 1, place the cold plate parts identical to those in Example 2 for micro-arc oxidation. After treatment, carry out an acidic salt spray test on the oxide film layer of the cold plate according to GJB1509A, 192h After visual inspection, the appearance is uniform, and there is no corrosion phenomenon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com