Preparation method of graphene composite aerogel absorbing material and application thereof

A technology of graphene composite and wave-absorbing materials, which is applied in the direction of graphene, electrical components, ferrous oxides, etc., can solve the problems of difficult expansion of effective bandwidth, mismatch of interface impedance, high dielectric loss, etc., and achieve Excellent absorbing performance, reduced density, and high absorbing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

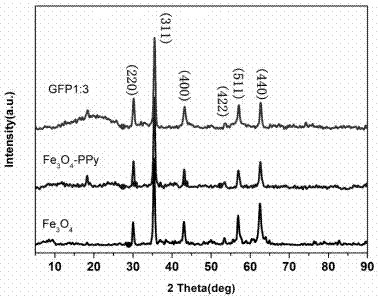

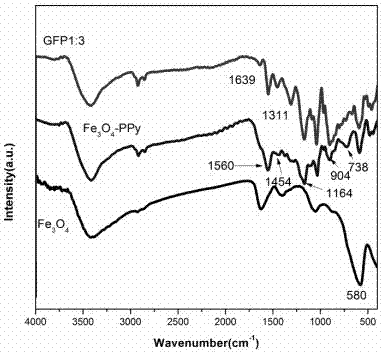

[0042] In this example, control Fe 3 o 4 The mass ratio to pyrrole monomer is 1:0.5802, the core-shell structure Fe 3 o 4 / PPy (polypyrrole) and graphene oxide mass ratio is 3:1, and the mass ratio of ethylenediamine and graphene oxide is 0.3-1:1 ;

[0043] The specific preparation steps of graphene composite airgel are as follows:

[0044] 1. First weigh 2.7g FeCl 3 ·6H 2 O was dissolved in 80mL of ethylene glycol, and 7.2g of sodium acetate and 2.0g of polyethylene glycol 400 were added while stirring, and the stirring was continued until a uniform yellow viscous material was formed, and the yellow viscous material was put into a hydrothermal reaction kettle, Put it into an oven preheated to 200°C and maintain this temperature for 8h. After the reaction is over, cool naturally, separate with water magnetically, wash with distilled water and ethanol three times successively, and dry under vacuum at 60°C to obtain the product Fe 3 o 4 particle.

[0045] 2. Then weigh...

Embodiment 2

[0057] The preparation steps of graphene composite airgel in this embodiment are as follows:

[0058] 1. Dissolve 4.31g of 4,4'-diaminodiphenyl ether (ODA) in 51g of DMAc (dimethylacetamide), add 4.69g of pyromellitic anhydride (PMDA) after it is completely dissolved, and keep at 0°C After reacting for 5h, the above solution was added to distilled water at 0°C to precipitate, washed and dried. Then the precipitate is dispersed in water, and triethylamine is added dropwise until forming a uniform aqueous solution, and it is configured as a uniform water-soluble polyamic acid triethylamine salt solution (in practical applications, the concentration range of the polymer A solution is between 15% and 15%). 5%-20wt%, can realize the purpose of the invention).

[0059] 2. Prepare 20 mL of graphene oxide aqueous dispersion with a concentration of 2 mg / mL (in specific applications, the concentration of GO aqueous dispersion can be selected within the range of 1.0-10 mg / mL), and add 6...

Embodiment 3

[0064] The preparation steps of graphene composite airgel in this embodiment are as follows:

[0065] 1. Fe 3 o 4 The preparation of nanoparticles is the same as Step 1 of Example 1.

[0066] 2. Weigh 0.5g Fe 3 o 4 The particles were dispersed in distilled water, and then weighed 9g FeCl 3 Continue to dissolve and react for 3h. Add 20 mL of an aqueous solution of sodium dodecylsulfonate with a mass fraction of 5.8%, add 0.4 mL of aniline monomer (mass about 0.4080 g) drop by drop, and react for 12 hours. Magnetic separation of water, washing and drying to obtain Fe 3 o 4 - PANI core-shell structure particles (whose shell thickness is 80-100 nm).

[0067] 3. Prepare 20 mL of 3 mg / mL GO aqueous solution, add 20 mg of ascorbic acid and 120 mg of the above core-shell particles, react at 90°C for 6 hours to obtain a graphene composite hydrogel, and finally freeze-dry to obtain a graphene composite airgel. The freeze-drying parameters are -50°C, 20Pa, 48h.

[0068] The gra...

PUM

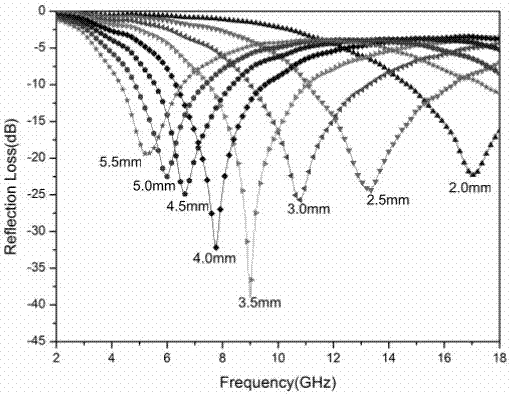

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Return loss | aaaaa | aaaaa |

| Absorption bandwidth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com