A method for preparing a reinforced polymethacrylimide foam composite material

A technology of polymethacrylimide and composite materials, which is applied in the field of preparation of polymethacrylimide foam composite materials, can solve the problem that the wave-absorbing material with foam structure cannot be prepared and the distribution uniformity of wave-absorbing particles is difficult to control , The absorption frequency band is not wide enough to achieve the effect of improving structural integrity and anti-deformation ability, realizing the integration of structure and function, and outstanding compressive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

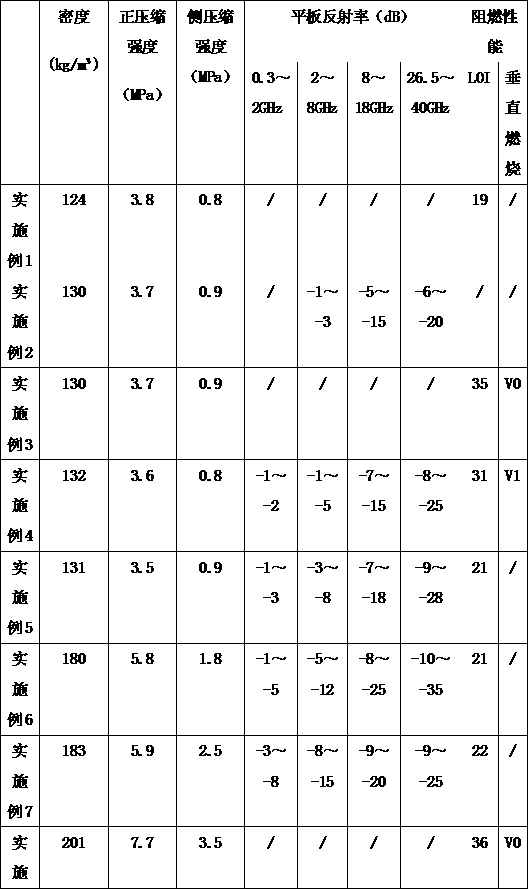

Examples

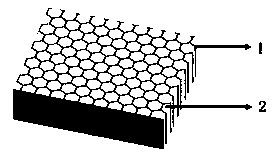

Embodiment 1

[0041] Put the honeycomb into the mold of the required shape first, and then put the mesh number of 8 to 30 mesh and the bulk density of 75±10kg / m 3 Polymethacrylimide pre-expanded particles filled to a density of 50±5 kg / m 3 In the regular hexagonal aramid honeycomb hole, the mold is sealed and foamed by in-mold foaming technology or molding. The specific foaming process is: preheat at 150°C for 1 hour, and then foam at 220°C for 2 hours , and finally cured at 180°C for 4 hours to obtain a reinforced polymethacrylimide foam composite material.

Embodiment 2

[0043] Firstly, 30wt% of superconducting carbon black (ECPEC600JD) as a wave absorbing agent, 0.3wt% of guanidine-based wetting agent and 10wt% of cetyltrimethylammonium bromide as a dispersing agent were passed through the alcohol solution at high speed. Disperse the functional filler in the solution by shearing to obtain a mixture solution; then the mesh number is 8-30 mesh and the bulk density is 75±10kg / m 3 The functional polymethacrylimide obtained by dispersing 45wt% of polymethacrylimide pre-expanded particles into the mixture 1 to obtain the mixture 2, drying the mixture 2 and mixing it with the binder epoxy resin 5wt% uniformly Pre-expanded particle mixture 3;

[0044] Put the honeycomb into the mold of the desired shape, fill the mixture 3 to a density of 50±5 kg / m 3 In the regular hexagonal aramid honeycomb 30wt% hole, the mold is sealed and treated by in-mold foaming technology. The specific foaming process is: preheating at 150°C for 1 hour, then foaming at 220°C...

Embodiment 3

[0048] First, 30wt% of the flame retardant calcium carbonate, 0.1wt% of the guanidinium-based sizing agent and 10wt% of the dispersant polyethylene wax are dispersed in the solution by high-speed shearing in the acetone solution to obtain a mixture solution. 1; then the mesh number is 8 to 30 mesh and the bulk density is 75±10kg / m 3 45wt% of polymethacrylimide pre-expanded particles are dispersed into mixture 1 to obtain mixture 2, and the functional polymethacrylic obtained by mixing uniformly with 5 wt% of binder acrylic coupling agent after drying mixture 2 Imide pre-expanded particle mixture 3;

[0049] Put the honeycomb into the mold of the desired shape, fill the mixture 3 to a density of 50±5 kg / m 3 In the regular hexagonal aramid honeycomb 30wt% hole, the mold is sealed and processed by in-mold foaming technology. The specific foaming process is: preheat at 150°C for 2 hours, then foam at 220°C for 3 hours, and finally After curing at 180°C for 1 hour, a reinforced p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com