Dot-line engaged bevel gear pair high in bearing capability and low in vibration

A technology of bearing capacity and helical gear pair, which is applied in the direction of gear transmission, belt/chain/gear, transmission device, etc., can solve the problems of shortened service life, increased working noise of helical gear pair, etc., and achieve large load capacity and low noise Low, little vibration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

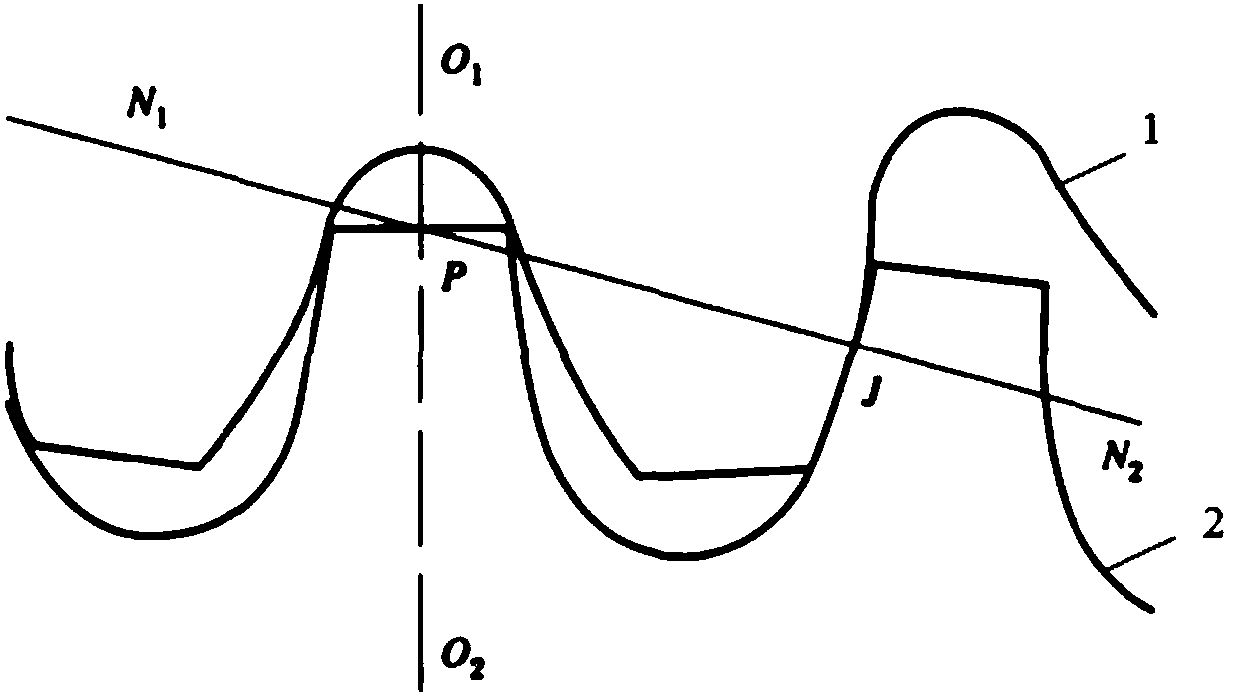

[0045] Such as figure 1 As shown, this embodiment provides a point-line meshing helical gear pair with high load capacity and low vibration, including a first helical gear 1 and a second helical gear 2 meshing with each other.

[0046] According to the design steps of the above-mentioned helical gear pair, the design parameters are optimized. In addition, the design parameters of the conventional helical gear pair are also given. The specific numerical optimization results of the above-mentioned design parameters are as follows:

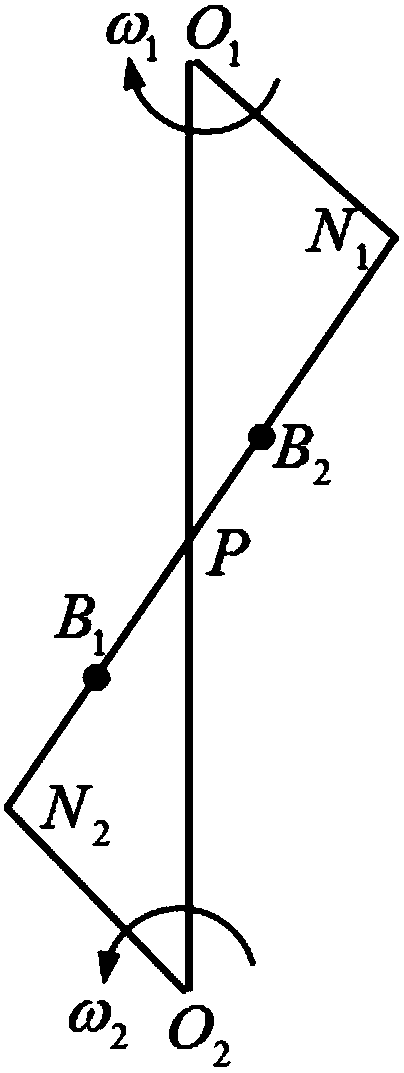

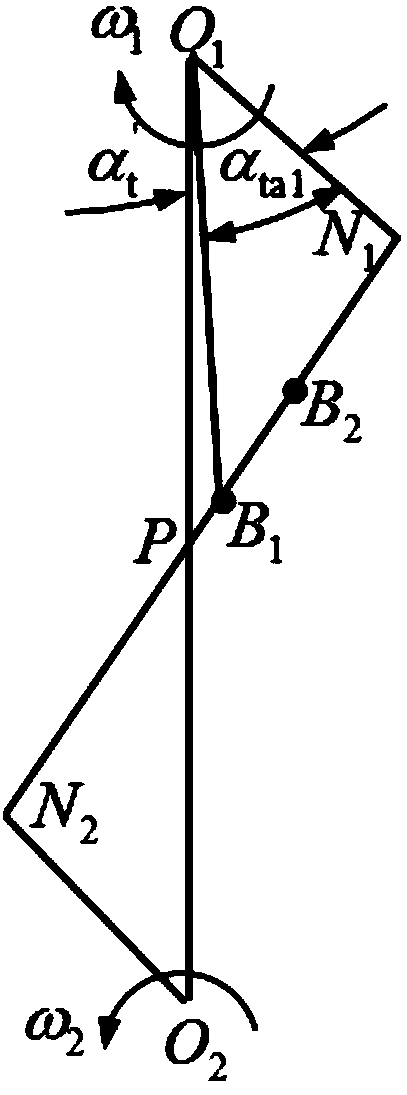

[0047] 1) if figure 2 As shown, the conventional helical gear pair meshing transmission is also a general meshing situation, that is, the meshing situation of both the front and rear nodes, and the design parameters are preferably as follows:

[0048] z 1 =16,z 2 =87,m n1 = 6 mm, m n2 =6mm, α n1 = 20°, α n2 =20°, β 1 =14.18°, β 2 =-14.18°, x n1 =0.415,x n2 =-1.7105, θ t1 =0.0163rad, θ t2 =0.0163rad, θ tα' =0.0071rad, α' t =0.2747r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com