Antisymmetric involute plastic gear

A technology of plastic gears and involutes, applied in belt/chain/gear, components with teeth, portable lifting devices, etc. Long wear life, good elasticity, low noise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

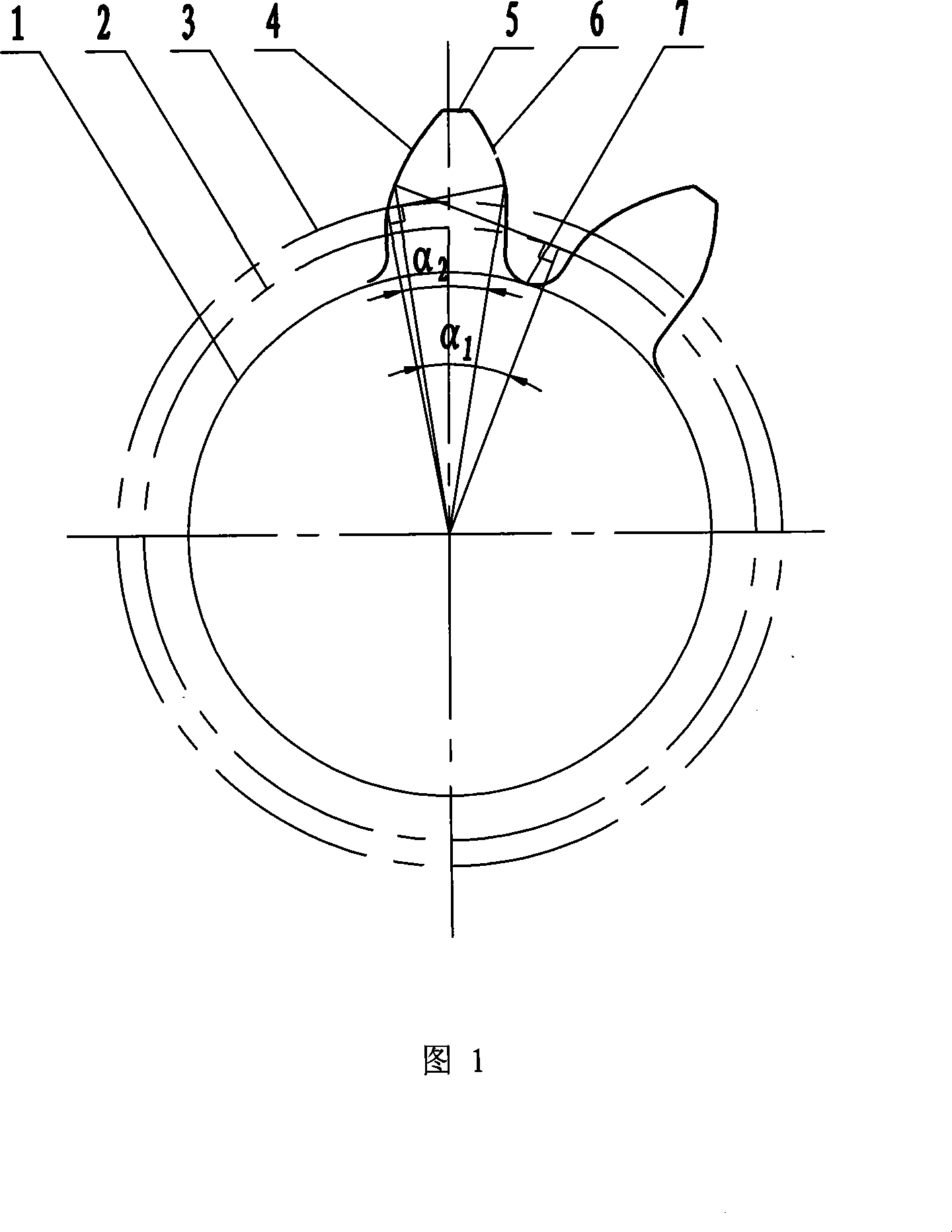

[0014] The tooth shape of the gear is a large pressure angle involute tooth profile 4 generated by the dedendum circle 1 and a small diameter base circle 2, a small pressure angle involute tooth profile 6 generated by a large diameter base circle 3, an addendum 5 and a transition Composed of curve 7.

[0015] for alpha 1 >α 2 Time:

[0016] by alpha 1 =15°, α 2 =14.5°, m=1.25, z=24, h a1 * = 1.0, h a2 * =0.95, c 1 * =0.35, c 2 * =0.4, m a = 0.4 / 24 = 0.0167.

[0017] got d b1 =mzcosα 1 =1.25×24cos15°=28.98(mm)

[0018] d b2 =mzcosα 2 =1.25×24cos14.5°=29.04(mm)

[0019] d a =(z+2h a1 * )m=(24+2×1)×1.25=32.5(mm)

[0020] S a = d b1 m a =28.98×0.0167=0.483966(mm)

[0021] d f =(z-2h a1 * -2c 1 * )m=(24-2×1-2×0.35)×1.25=26.625(mm)

[0022] According to the base circle diameter d b1 and d b2 For the same reference and opposite directions, the involute tooth profile 4 with a large pressure angle and the involute tooth profile 6 with a small pressure...

Embodiment approach 2

[0024] for alpha 1 >α 2 Time:

[0025] by alpha 1 =30°, α 2 =14.5°, m=1.25, z=24, h a1 * = 1.0, h a2 * =0.90, c1 * =0.3, c 2 * =0.4, m a =0.325 / 24=0.0135.

[0026] got d b1 =mzcosα 1 =1.25×24cos30°=25.98(mm)

[0027] d b2 =mzcosα 2 =1.25×24cos14.5°=29.04(mm)

[0028] d a =(z+2h a1 * )m=(24+2×1)×1.25=32.5(mm)

[0029] S a = d b1 m a =25.98×0.0135=0.35073(mm)

[0030] d f =(z-2h a1 * -2c 1 * )m=(24-2×1-2×0.3)×1.25=26.75(mm)

[0031] Diameter d at tooth top 5 a The arc length between the two involutes is 2.3364mm. Since the diameter d of the dedendum circle 1 f greater than the diameter d of the small diameter base circle 2 b1 , so the formed large pressure angle involute tooth profile 4 is completely involute; due to the diameter d of the dedendum circle 1 f smaller than the diameter d of the large diameter base circle 3 b2 , so the small pressure angle involute tooth profile 6 formed is divided into two parts: the involute between the large d...

Embodiment approach 3

[0033] for alpha 1 >α 2 Time:

[0034] by alpha 1 = 45°, α 2 =14.5°, m=1.25, z=24, h a1 * = 1.0, h a2 * = 1.0, c 1 * =0.45, c 2 * =0.45, m a =0.25 / 24=0.0104.

[0035] got d b1 =mzcosα 1 =1.25×24cos45°=21.21(mm)

[0036] d b2 =mzcosα 2 =1.25×24cos14.5°=29.04(mm)

[0037] d a =(z+2ha1 * )m=(24+2×1)×1.25=32.5(mm)

[0038] S a = d b1 m a =21.21×0.0104=0.220584(mm)

[0039] d f =(z-2h a1 * -2c 1 * )m=(24-2×1-2×0.45)×1.25=26.375(mm)

[0040] Diameter d at tooth top 5 a The arc length between the two involutes is 5.4899mm. Since the diameter d of the dedendum circle 1 f greater than the diameter d of the small diameter base circle 2 b1 , so the formed large pressure angle involute tooth profile 4 is completely involute; due to the diameter d of the dedendum circle 1 f smaller than the diameter d of the large diameter base circle 3 b2 , so the small pressure angle involute tooth profile 6 formed is divided into two parts: the involute between the la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com