Tooth profile design of dual-pressure angle involute helical tooth externally-meshed cylindrical gear

A cylindrical gear, double pressure angle technology, applied in the direction of elements with teeth, belts/chains/gears, mechanical equipment, etc., can solve problems such as difficulty in meeting equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

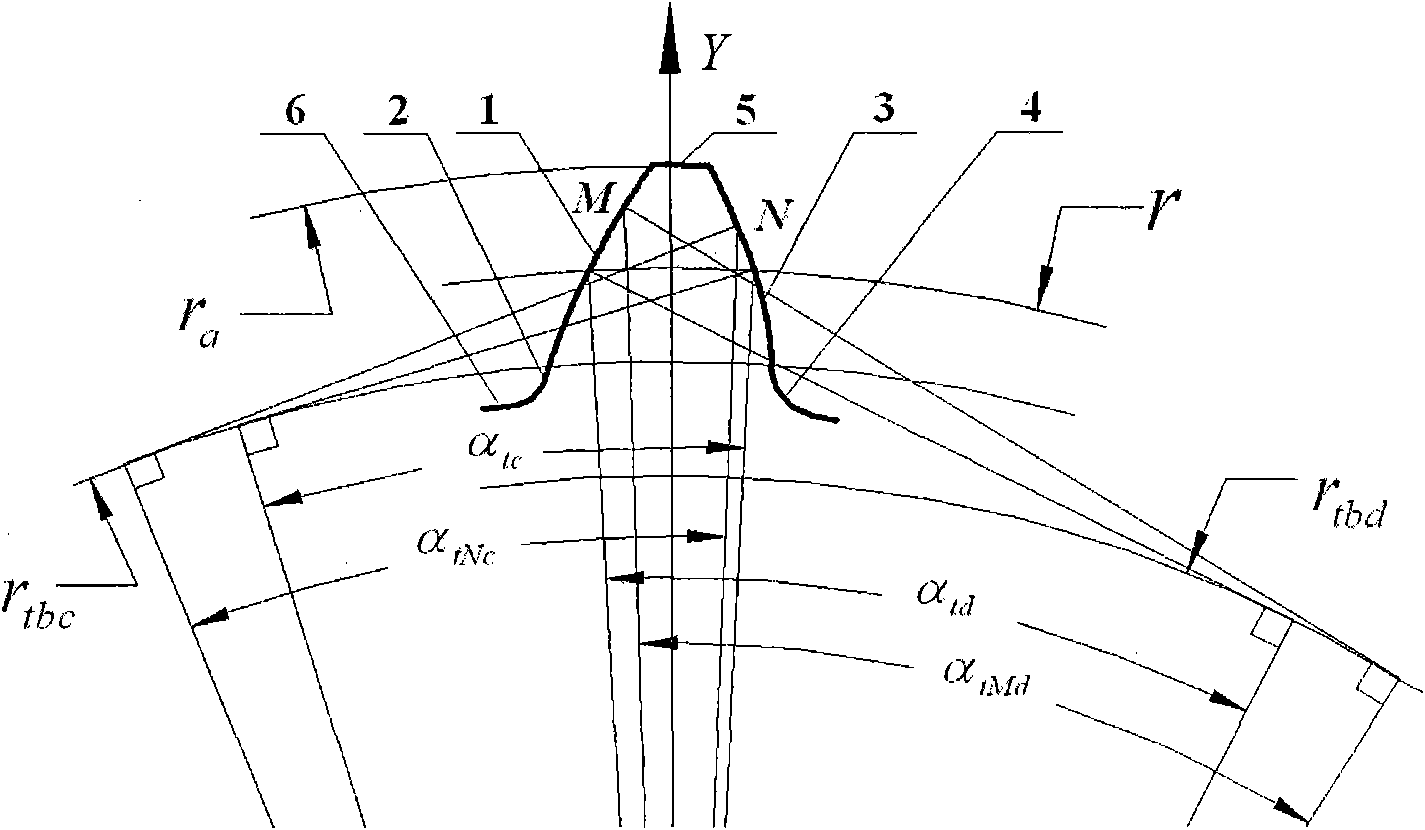

[0062] According to the design requirements of the double pressure angle involute helical external meshing cylindrical gear that needs to be designed, select the standard normal surface modulus, the pressure angle of the normal surface driving side and the driven side involute at the indexing circle, the normal surface Active side addendum height coefficient, radial clearance coefficient, number of teeth, helix angle, tooth thickness and other basic design parameters, and then convert the normal surface parameters into corresponding end surface parameters according to the conversion relationship between the normal surface and end surface parameters.

[0063] According to the end modulus m t , the number of teeth z, the coefficient of addendum height on the driving side of the end face The value of , according to the parameter equation of the addendum circle, can be obtained figure 1 Middle addendum circle curve 5;

[0064] According to the end modulus m t , the number of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com