Cold extruding forming method used for automotive spline sleeve part

A spline sleeve and cold extrusion technology are applied in the direction of metal extrusion, metal extrusion dies, metal extrusion control equipment, etc., which can solve the problems of bending resistance, unsatisfactory shear strength, poor density of powder metallurgy tooth structure, The problem of low material utilization rate can solve the problem of dissatisfaction with metal mold filling, good mechanical properties of parts, and high material utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

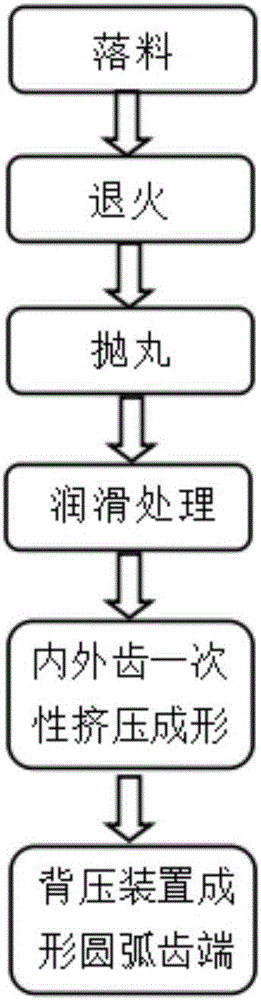

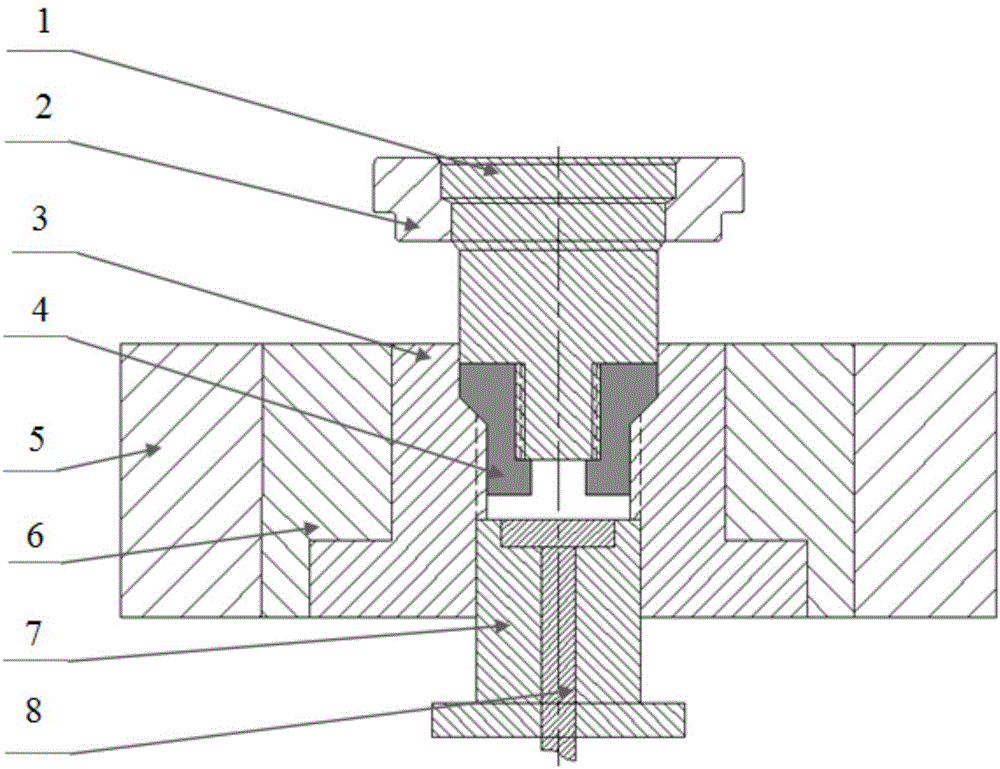

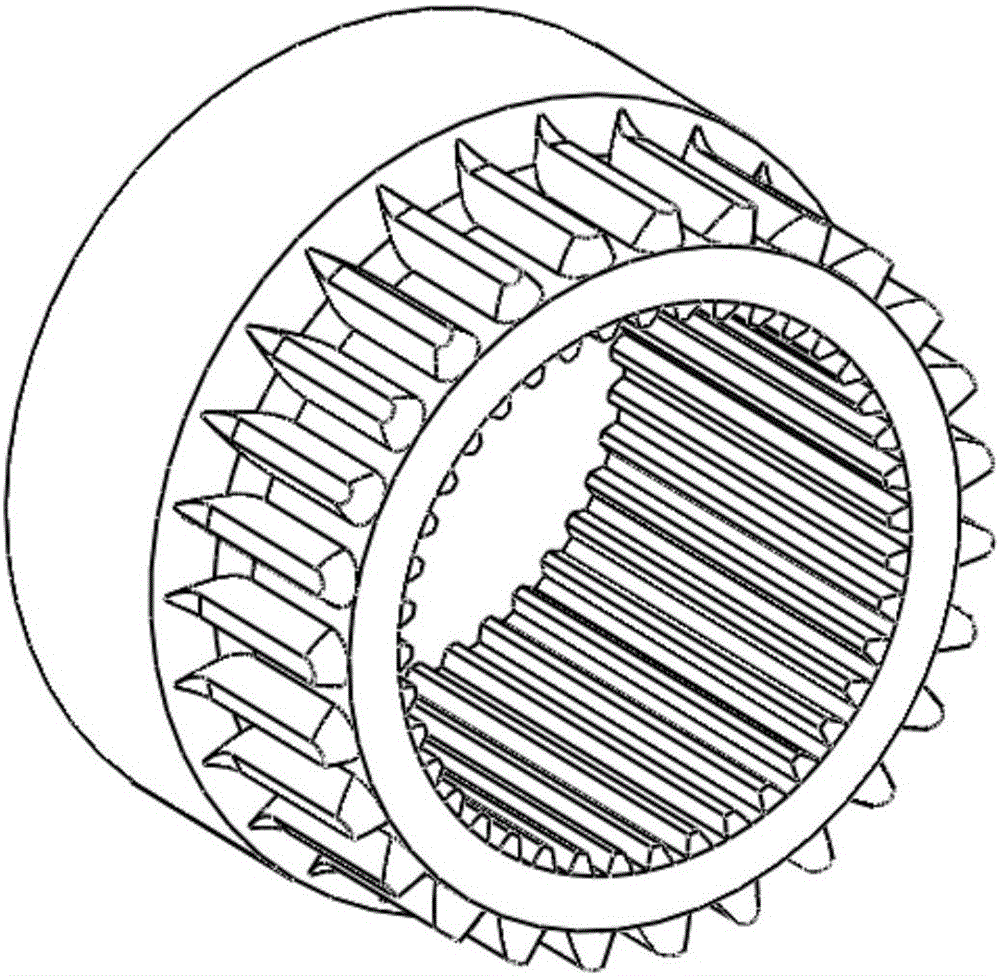

[0029] A cold extrusion forming method of a spline sleeve part for a vehicle, the part structure is as follows image 3 As shown, the forming process is as figure 1 As shown, it includes blanking, annealing, shot blasting, lubrication treatment, one-time extrusion forming of internal and external teeth, back pressure device forming circular arc tooth ends and other processes. The specific steps are as follows:

[0030] (1) Prepare the spline sleeve blank;

[0031] (2) Annealing to soften the blank; the process conditions are: under the protection of nitrogen atmosphere, heat preservation at 860°C for 8 hours, and then cool with the furnace to below 450°C;

[0032] (3) Shot blasting treatment to eliminate burrs and oxide scales on the surface of the blank (shot blasting):

[0033] The process conditions are: use pellets with a diameter of 0.6-1.0mm to treat for 10 minutes, so that the surface of the blank has no scale and the surface of the rust is bright and uniform;

[003...

Embodiment 2

[0042] A cold extrusion forming method of a spline sleeve part for a vehicle, the part structure is as follows Figure 4 As shown, the forming process specifically includes the following steps:

[0043] (1) Prepare blank;

[0044] (2) Annealing and softening;

[0045] The process conditions are: under the protection of nitrogen atmosphere, heat preservation at 880°C for 7 hours, and then cool down to below 450°C with the furnace;

[0046] (3) Shot blasting treatment;

[0047] The process conditions are: use pellets with a diameter of 0.6-1.0mm to treat for 18 minutes, so that the surface of the blank has no scale and the surface of the rust is bright and uniform;

[0048](4) Lubrication treatment;

[0049] The process conditions include the following steps in turn: degreasing for 7 minutes, cold water washing for 0.8 minutes, hot water washing for 0.8 minutes, pickling for 8 minutes, cold water washing for 0.8 minutes, hot water washing for 0.8 minutes, phosphating for 12 ...

Embodiment 3

[0056] A cold extrusion forming method of a spline sleeve part for a vehicle, the part structure is as follows Figure 5 As shown, the forming method specifically includes the following steps:

[0057] (1) Blanking;

[0058] (2) Annealing;

[0059] The process conditions are: under the protection of nitrogen atmosphere, heat preservation at 900°C for 7 hours, and then cool to below 450°C with the furnace;

[0060] (3) shot blasting;

[0061] The process conditions are: use pellets with a diameter of 0.6-1.0mm to treat for 25 minutes, so that the surface of the blank has no scale and the surface of the rust is bright and uniform;

[0062] (4) lubrication;

[0063] The process conditions include the following steps in turn: degreasing for 10 minutes, cold water washing for 1 minute, hot water washing for 1 minute, pickling for 10 minutes, cold water washing for 1 minute, hot water washing for 1 minute, phosphating for 15 minutes, cold water washing for 1 minute, hot water wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com