Method for detecting gear tooth profile and spiral line by diaxon servocontrol

A technology of helix and gear teeth is applied in the measurement field of transmission mechanical gears, which can solve the problems of complex control system and difficult to improve accuracy, and achieve the effect of eliminating mechanical structure, simplifying circuit design and expanding application fields.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The purpose and effects of the present invention will become more apparent by referring to the accompanying drawings in detail of the present invention.

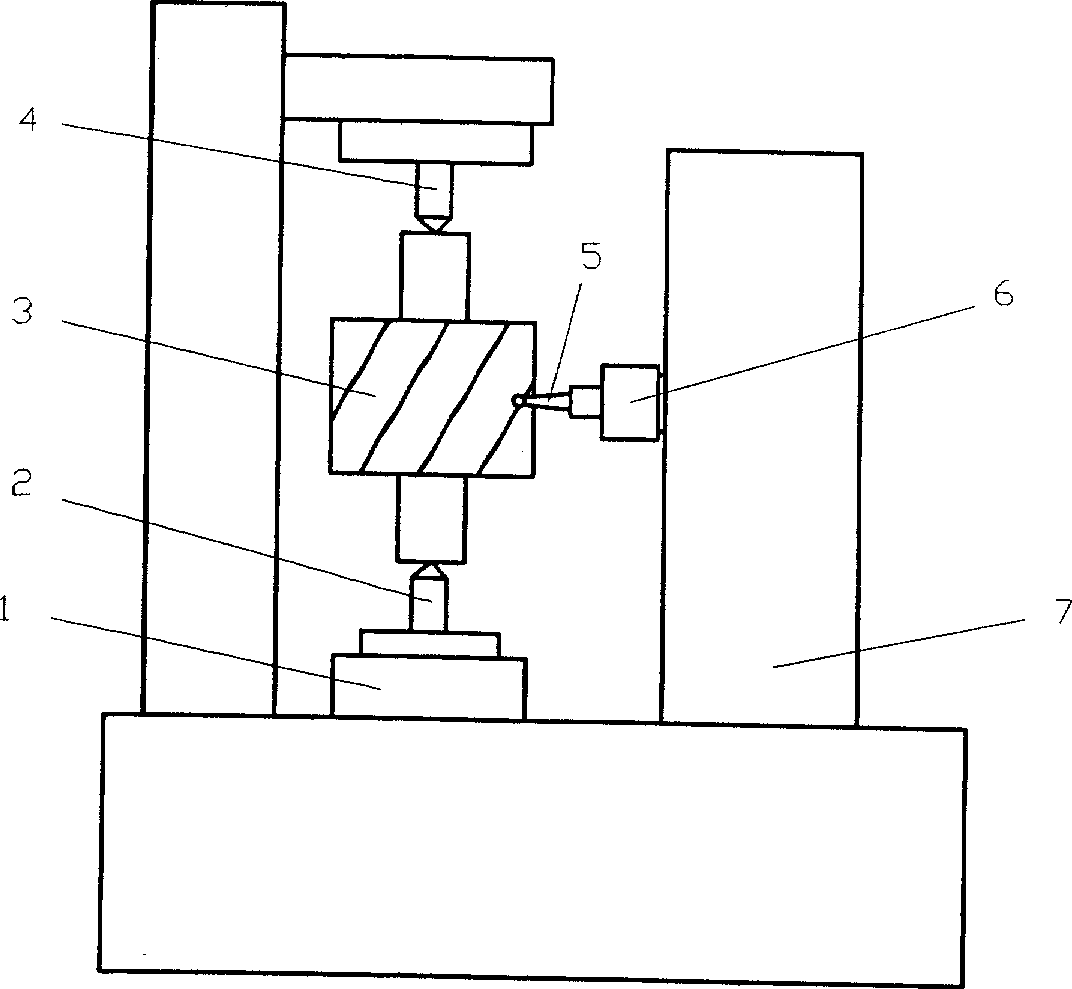

[0023] Such as figure 1 As shown, the tested gear 3 is installed on the rotary shaft 1 by the upper center 2 and the lower center 4, the displacement sensor 5 is installed on the measuring slider 6, and the probe of the displacement sensor contacts the gear teeth at the base circle position of the tested gear 3 On the surface, the measuring slider 6 can move along the tangent direction of the gear base circle and the direction of the gear axis (the up-down direction in the figure), and the column 7 can move along the normal direction of the gear base circle (the left-right direction in the figure).

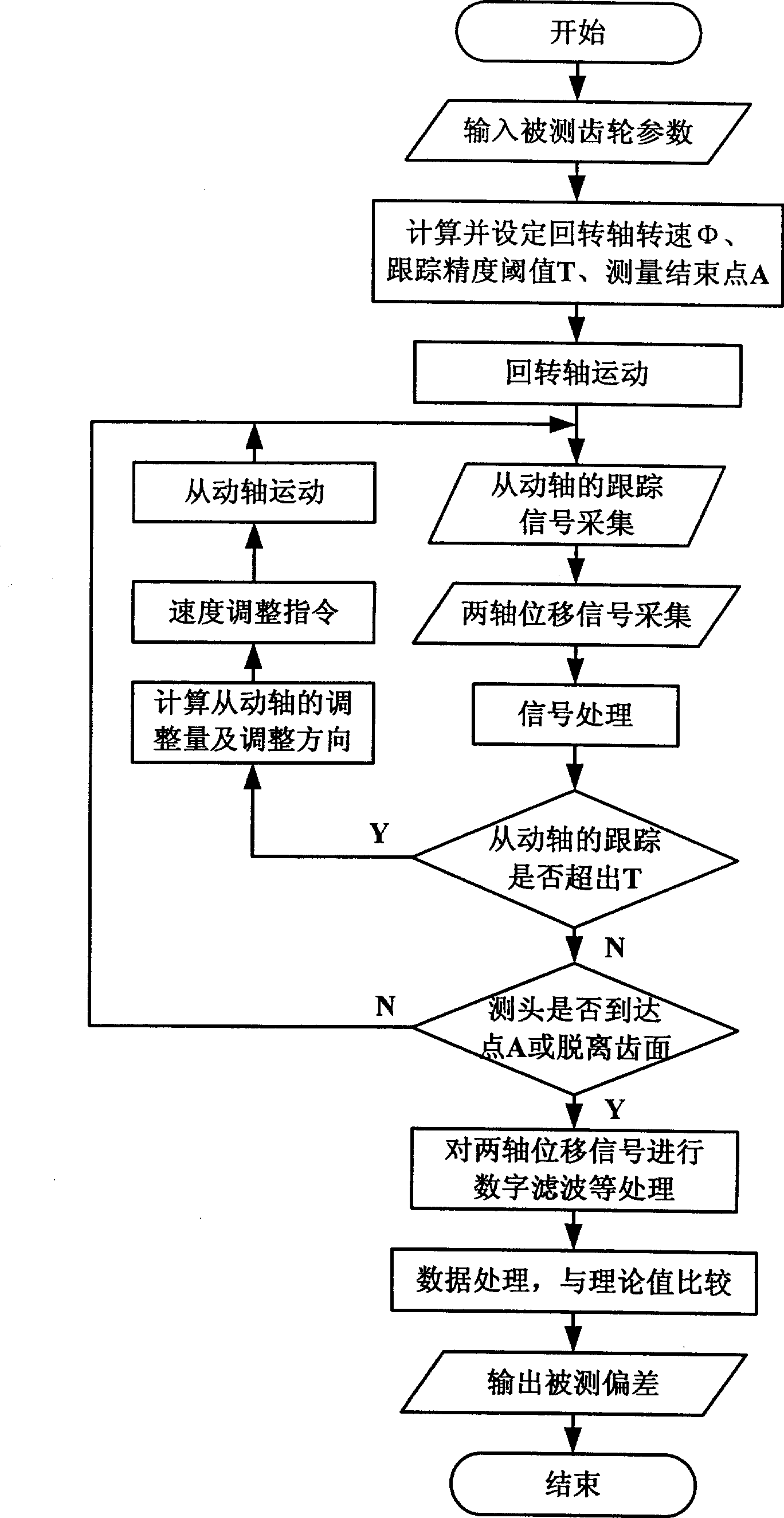

[0024] When measuring the gear tooth profile, first convert the measurement of the measured gear tooth profile into the measurement of the angular displacement of the gear rotation and the linear displacement in the tange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com