Rotary positive displacement hydraulic device

A hydraulic device and rotor technology, applied in the field of hydraulic devices, can solve the problems of insufficient rotor bearing structure with groove structure and failure to provide solutions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0023] In order to show that according to the technical scheme of the present invention, a new product series of hydraulic parts that is obviously different from the prior art, including quantitative, variable hydraulic pumps, motors and hydraulic variable speed transmissions, is now enumerated as shown in the accompanying drawings. Seven examples are described. in:

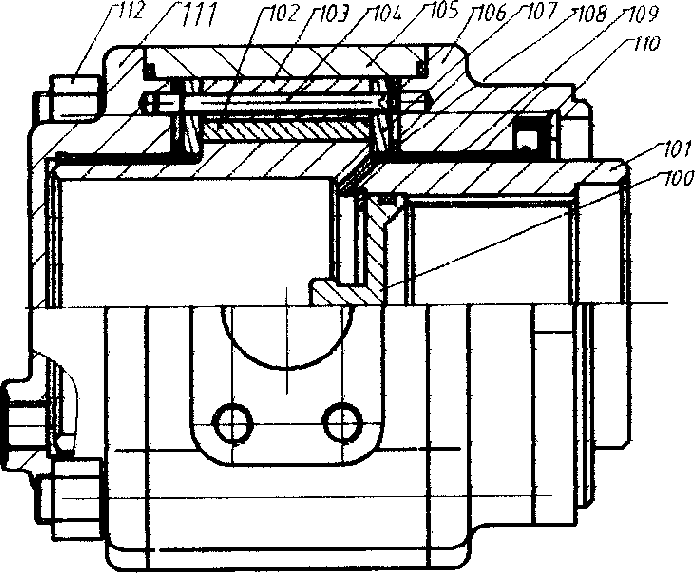

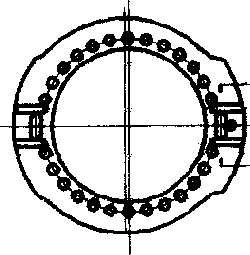

[0024] There are three basic types of fixed displacement hydraulic pumps and motors. The first type: the rotor bearing adopts DU bearing, as shown in the attached drawing Figure 1 to Figure 19As shown, one end of the inner hole of the rotor main component 101 is provided with a transmission inner spline, and the inner part of the spline is equipped with a sealing plate 100, and the sliders 102 are fitted in the slider grooves on the outer circumference to form a rotor component, and the outer circumference of the component is eccentric Bearing sleeve 103, the front surface of two floating valve plates formed b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com