Design method of high-order modified eccentric circular gear and non-circular gear pair conjugated with high-order modified circular gear

A technology of eccentric circular gears and non-circular gears, which is used in gear transmissions, elements with teeth, belts/chains/gears, etc., can solve the design and application of eccentric circular-noncircular gear pairs without high-order variation research, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0064]The design method of high-order modified eccentric circular gear and its conjugate non-circular gear pair, the specific steps are as follows:

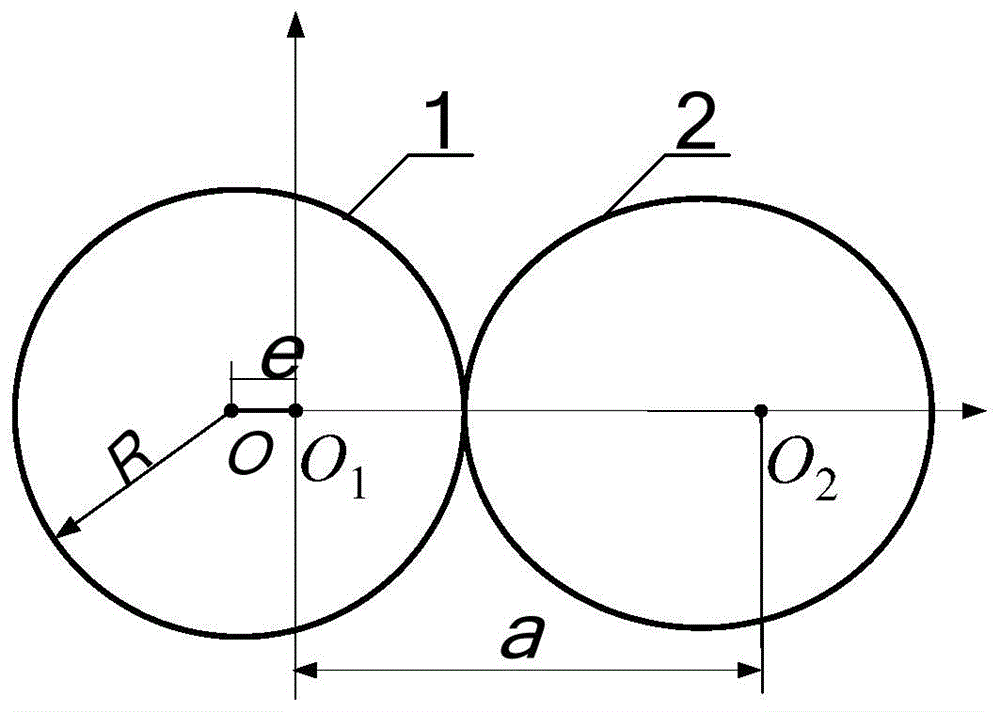

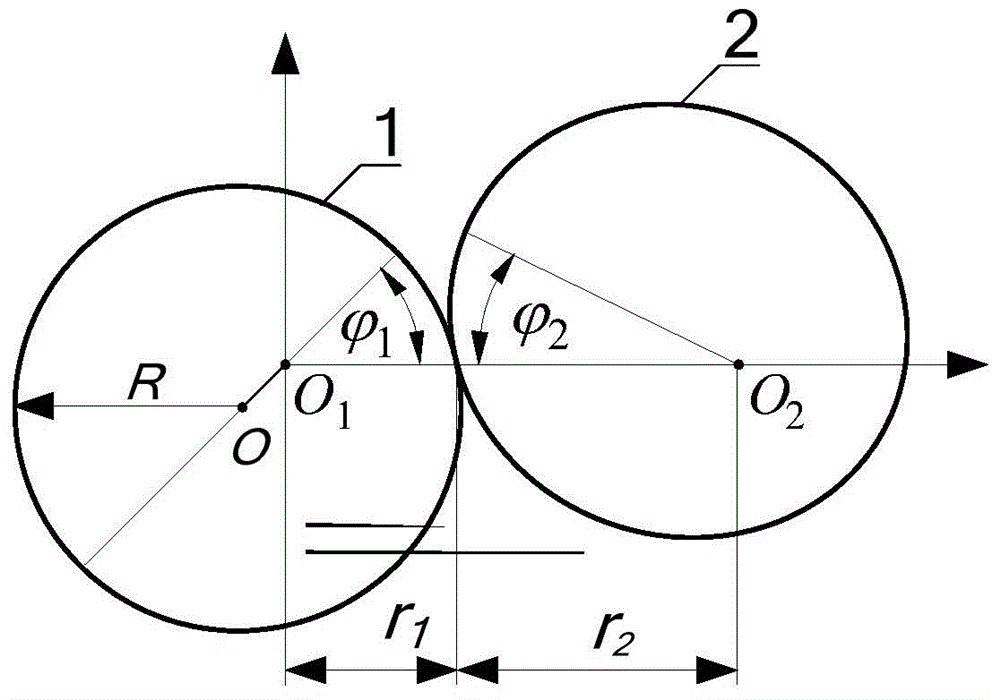

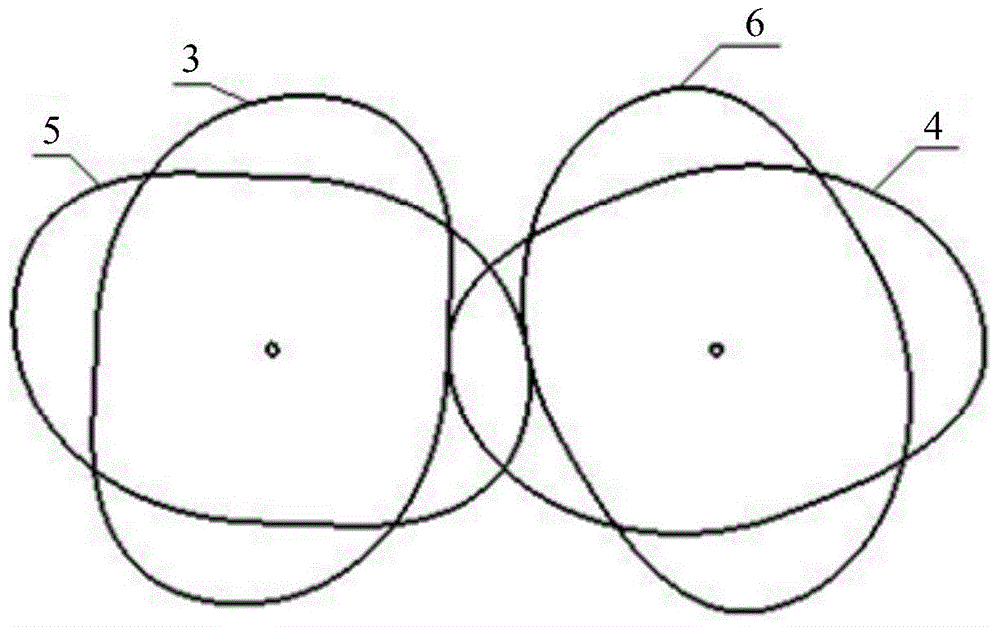

[0065] Step 1, such as Picture 1-1 and 1-2 As shown, the pitch curve equation of high-order modified eccentric circular gear 1 is established. The pitch curve of high-order modified eccentric circular gear 1 is changed by n 1 It is composed of nodal curve segments, and each nodal curve segment includes an asymmetric first denatured curve segment r 11 and the second denatured curve segment r 12 ;Angular displacement of high-order denatured eccentric gear 1 The corresponding radial direction in the first change cycle is ( The radial expressions corresponding to the remaining change periods are consistent with those of the first change period):

[0066]

[0067] In the formula, R is the radius of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com