Liquid nitrogen inner spraying type numerical control drilling and milling machine main shaft device

A spindle device, drilling and milling machine technology, applied in the direction of large fixed members, metal processing machinery parts, maintenance and safety accessories, etc., can solve the problems of not being able to process difficult-to-cut materials, ensure cutting accuracy, etc., and eliminate the utilization rate of liquid nitrogen Low, improve the processing range, and ensure the effect of processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

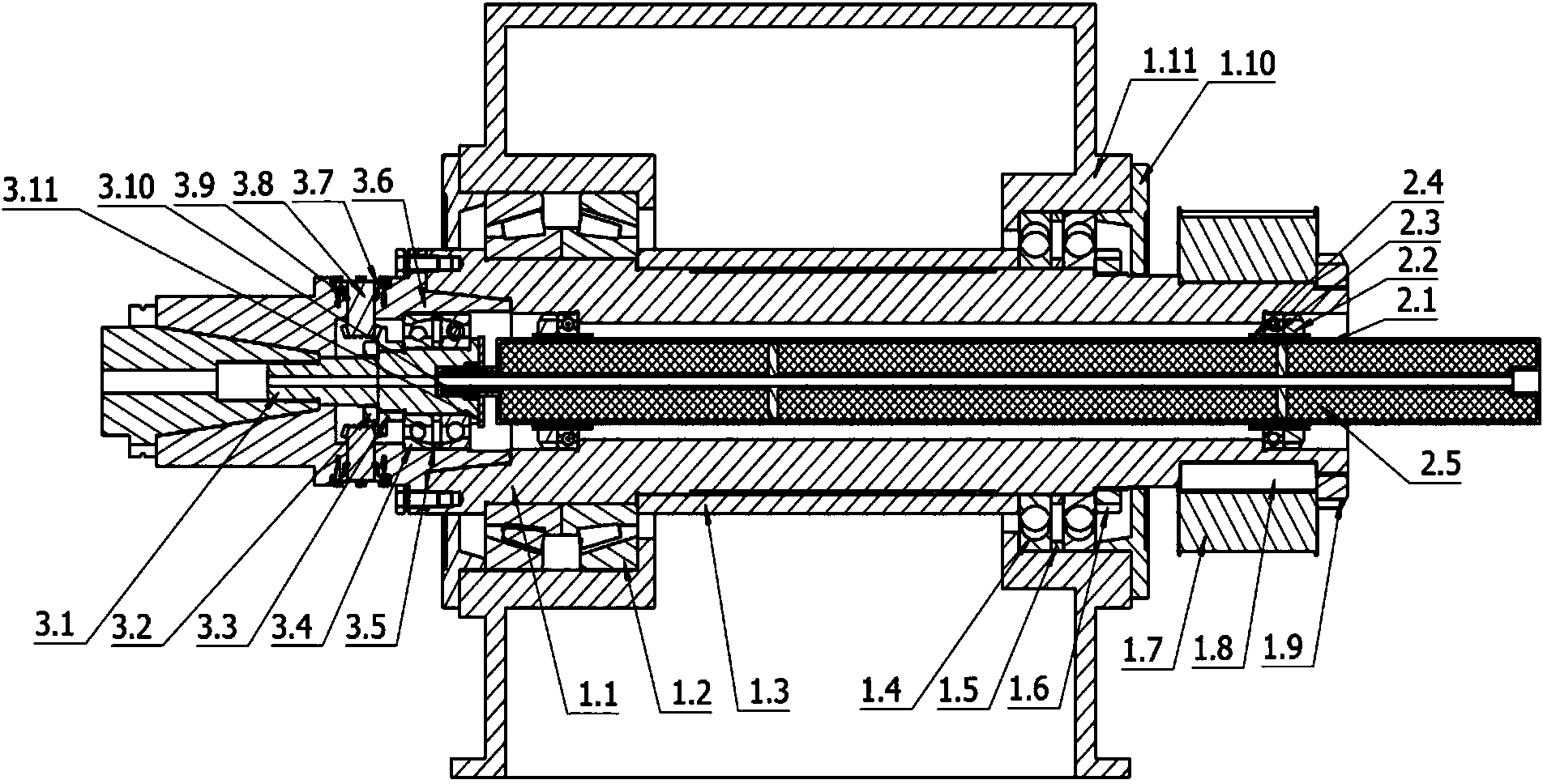

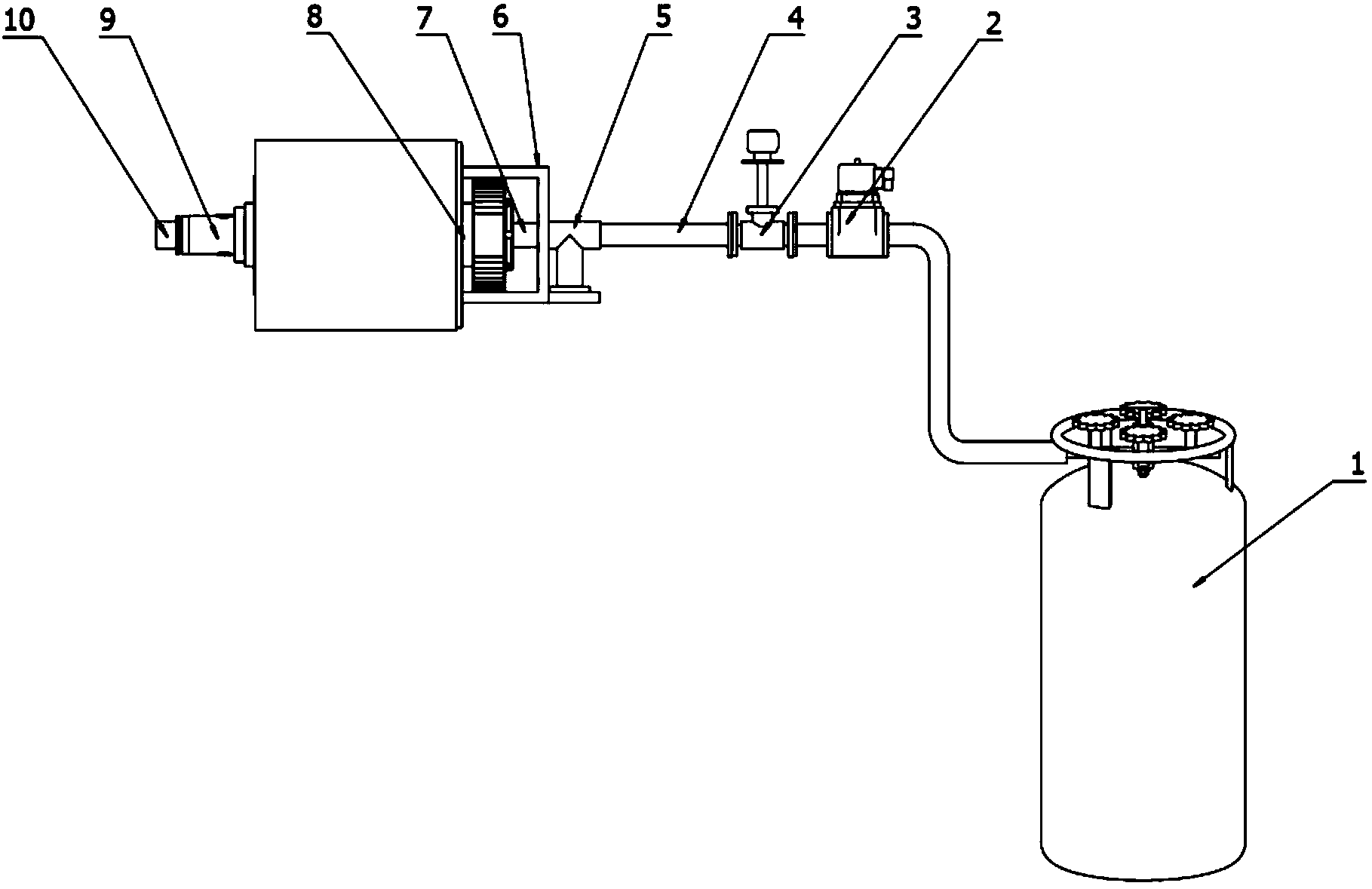

[0011] The specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings and technical solutions: the liquid nitrogen internal spray liquid supply method of the numerical control machine tool is to transform the machine tool spindle, the cutting fluid system is integrated with the machine tool spindle, and the liquid nitrogen is transported to the vacuum insulation hard The tube runs through the inner cavity of the hollow spindle and connects with the hollow pull stud, which is then connected with the hollow tool holder, and the liquid nitrogen is sprayed out from the fine holes near the cutting edge of the tool. The distance between the nozzle and the cutting surface can be within 1mm. Most of the liquid nitrogen is still in a liquid state when it is sprayed out, which improves the utilization rate of liquid nitrogen. The instantaneous temperature of the cutting area is controlled by controlling the flow of liqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com