Radial automatic drilling device for large-size compound cylinder

A drilling device and automatic technology, applied in the direction of boring/drilling, drilling/drilling equipment, and drilling templates for workpieces, etc., can solve the problems of low drilling efficiency and difficult tool setting, and improve processing range, avoid fiber tearing and delamination, and facilitate storage and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

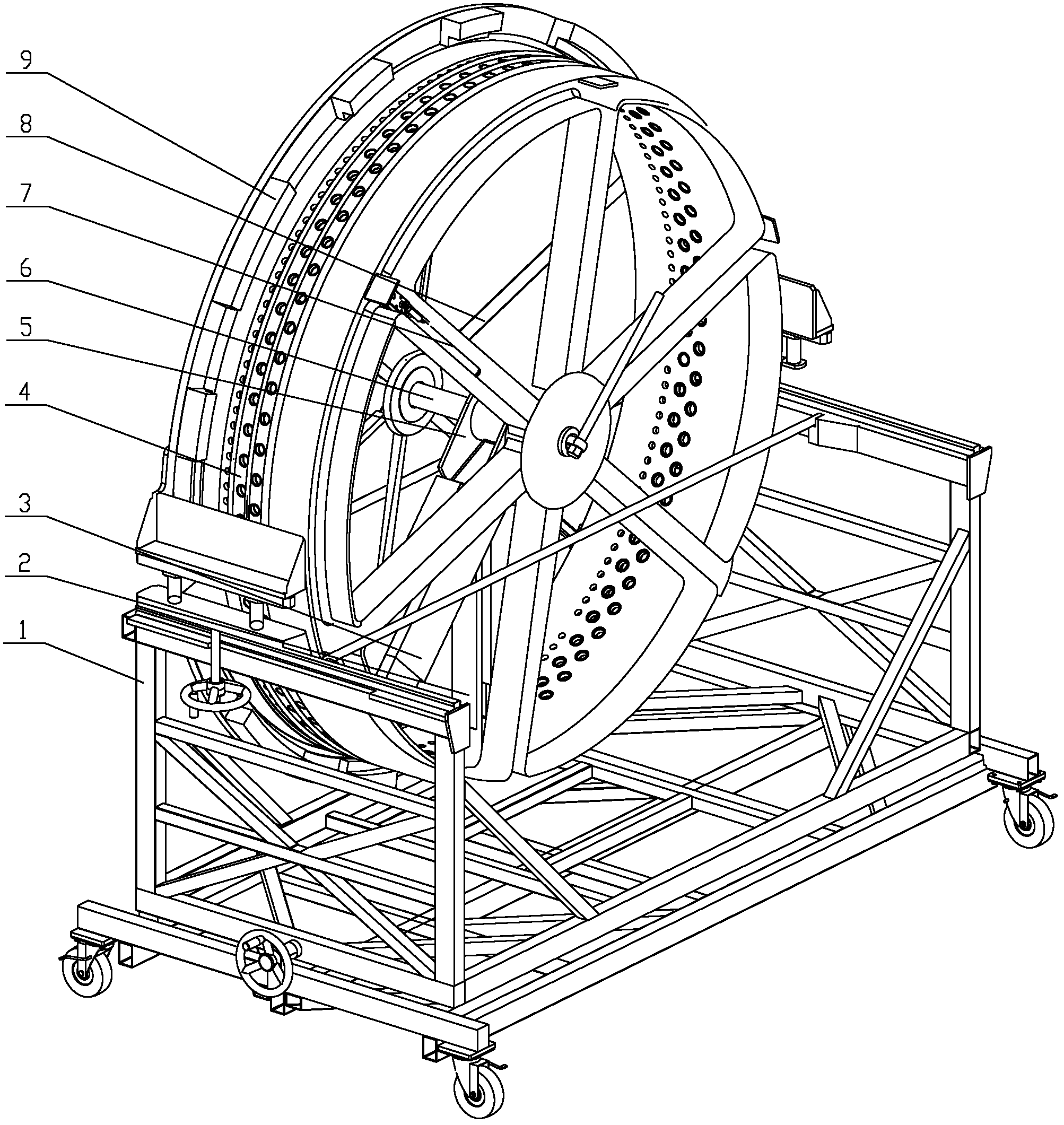

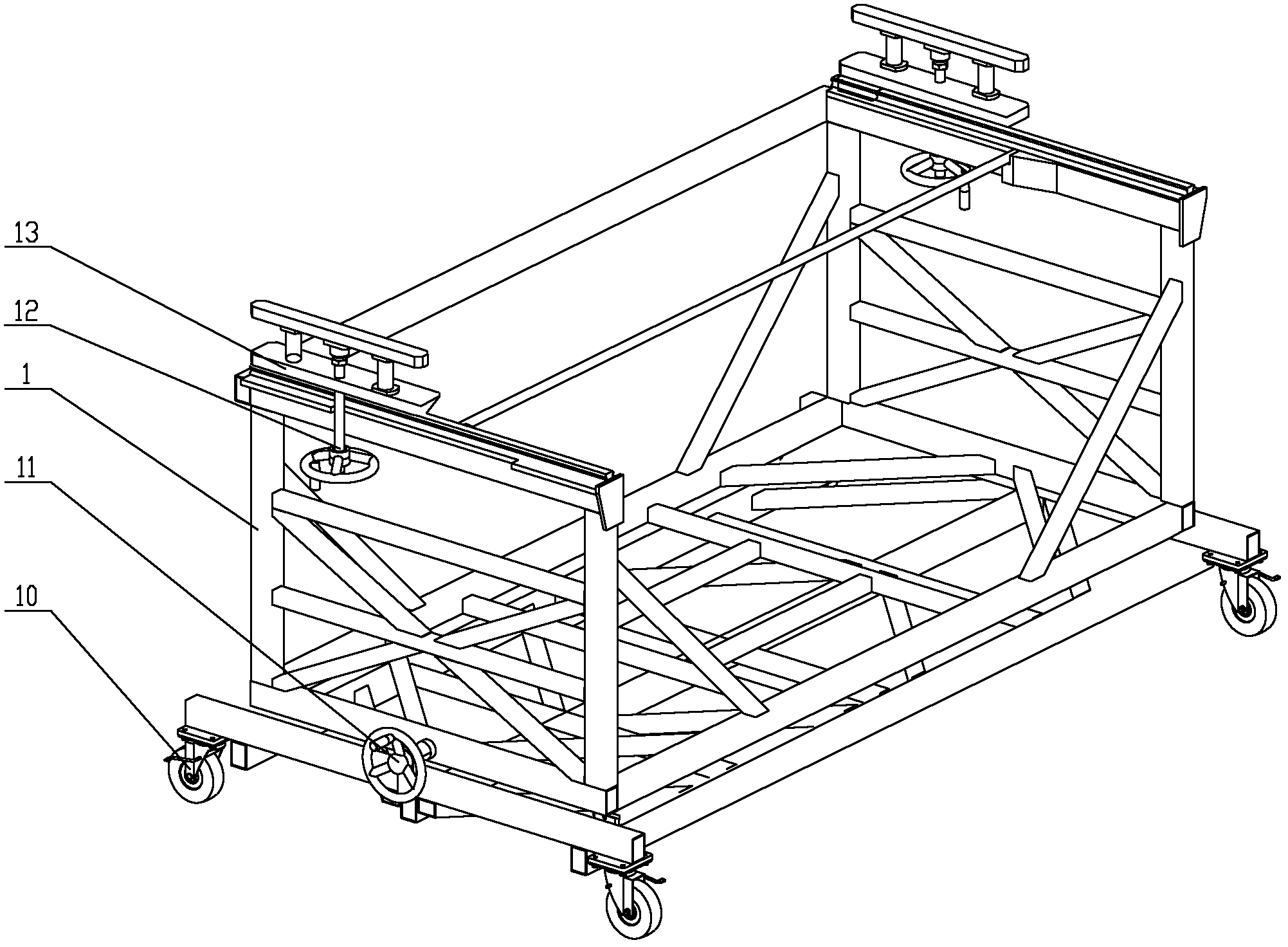

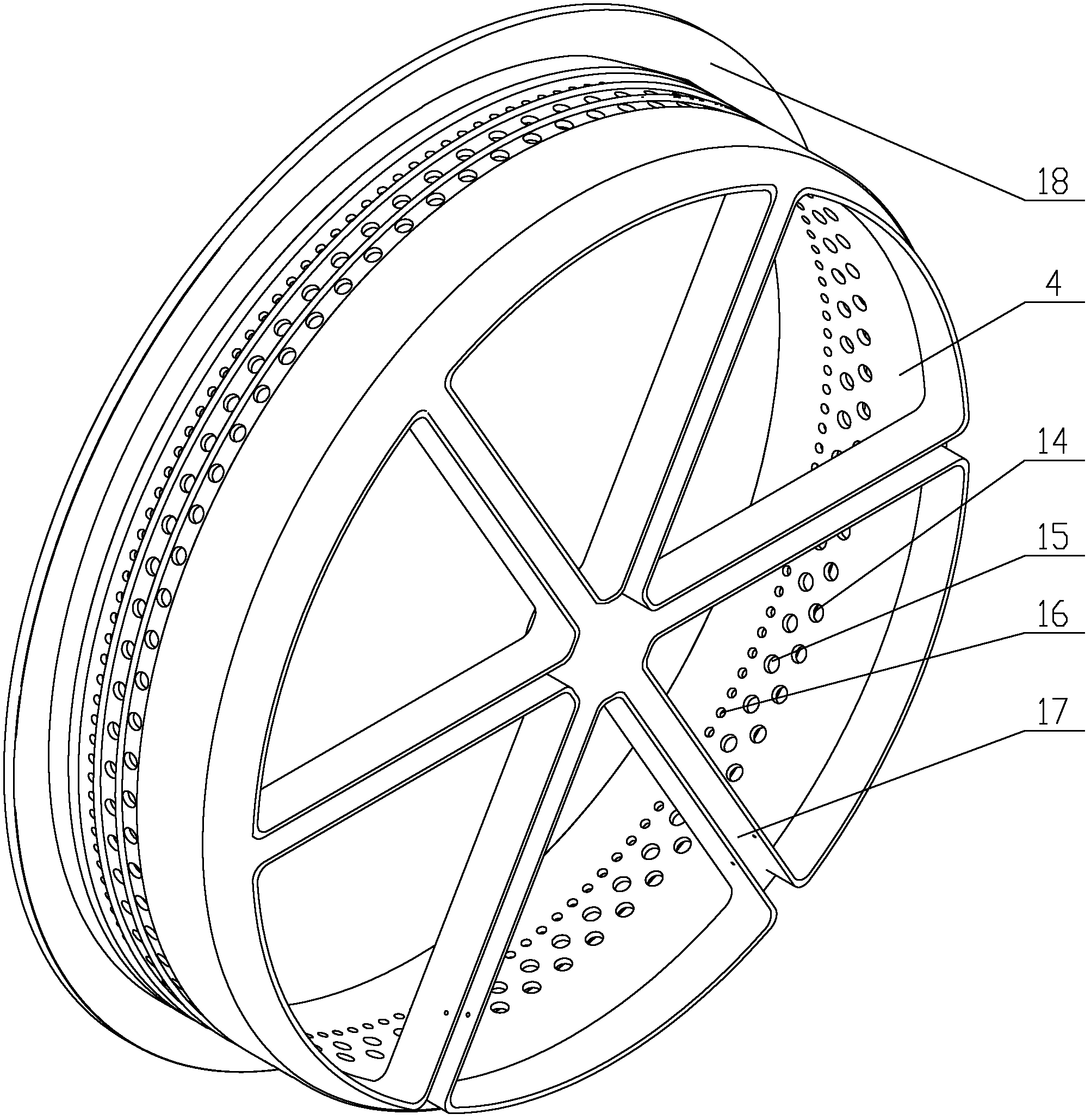

[0022] Specific embodiments of the present invention will be described in detail in combination with technical solutions and drawings.

[0023] like figure 1 As shown, the central axis of the drilling template 4 is placed horizontally, and one end of the mandrel 6 is inserted into the center of the chute 17 of the drilling template 4, and the other end is fixed by a bracket 8. The first drilling unit 2 and the second drilling unit 3 are respectively fixedly connected to the turntable 5, the center hole of the turntable 5 is coaxial with the center hole of the drilling template 4, and is penetrated by the mandrel 6, and the turntable 5 can be wound around the mandrel mandrel 6. Free rotation, no matter how the drilling template 4 rotates around its own axis, the first drilling unit 2 and the second drilling unit 3 are always in a free-sagging state under the action of their own gravity. One group of pads 9 are fixed on the flange 18 of the drilling template 4, and the purpose ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com