Turning and milling compound multi-shaft power head device

A power head, turning and milling technology, applied in the direction of driving devices, large fixed members, metal processing machinery parts, etc., can solve the problem that the power shaft cannot be installed on two planes crossing, the machine tool carrier cannot be flexibly installed, and large-scale processing cannot be satisfied and other problems, to achieve the effect of small space occupation, powerful functions and large processing range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The turning-milling composite multi-axis power head device of the present invention will be further described in detail in conjunction with the accompanying drawings:

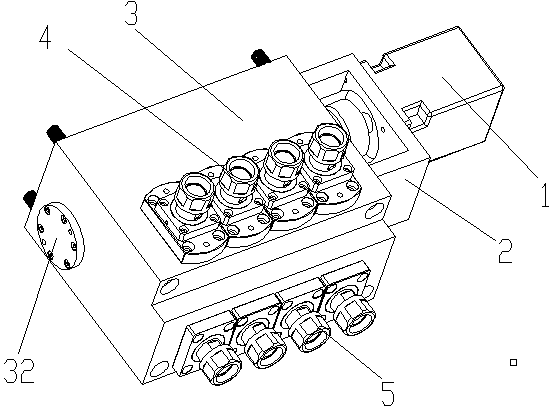

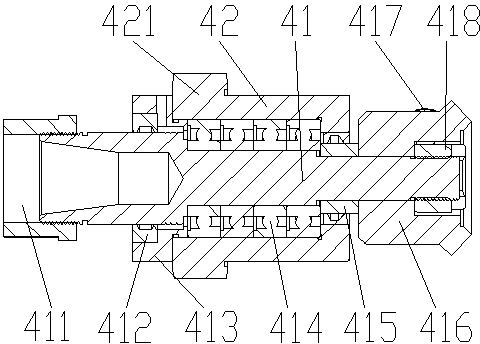

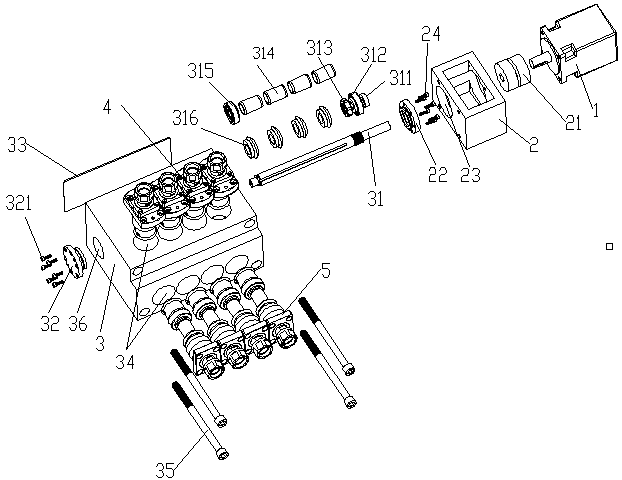

[0035] Such as Figure 1-6 Shown: a turning-milling composite multi-axis power head device according to the present invention, including a servo motor 1, a motor base 2 and a gearbox 3, the servo motor 1 is installed on the side of the motor base 2, and the motor base 2 is installed on the right side wall of the gear box 3, and two linkage shafts 21 are installed side by side in the motor base 2, and one of the linkage shafts 21 is installed on the rotating shaft of the servo motor 1; the gear box 3 A plurality of installation holes 34 are evenly provided on the two vertical surfaces, and the front axle string 4 and the side axle string 5 are respectively installed in the installation holes 34; the number of the installation holes 34 on the single vertical surface is 2 -8, and the number of correspondin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com