Electric field electrorheological jet polishing device

A technology of polishing device and spraying device, which is applied in the direction of explosion generating device, used abrasive processing device, abrasive spraying machine tool, etc., can solve the problem of small pollution, achieve the effect of increasing stability, reducing requirements and increasing safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] specific implementation plan

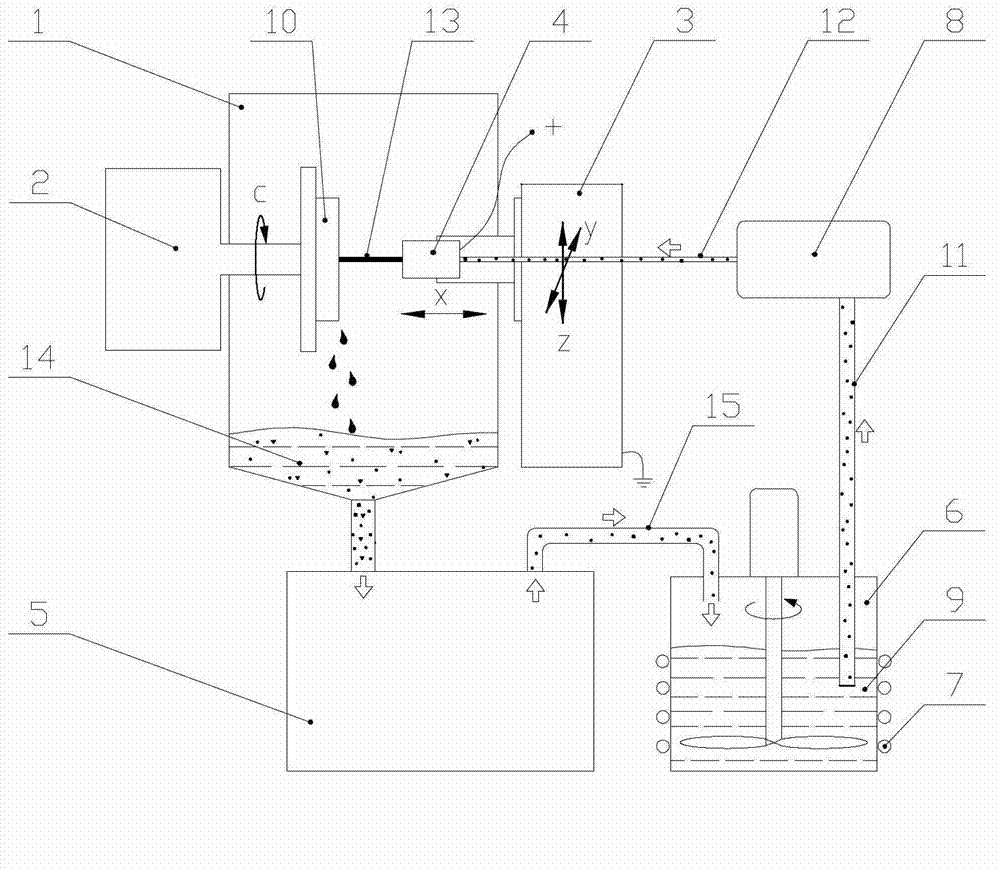

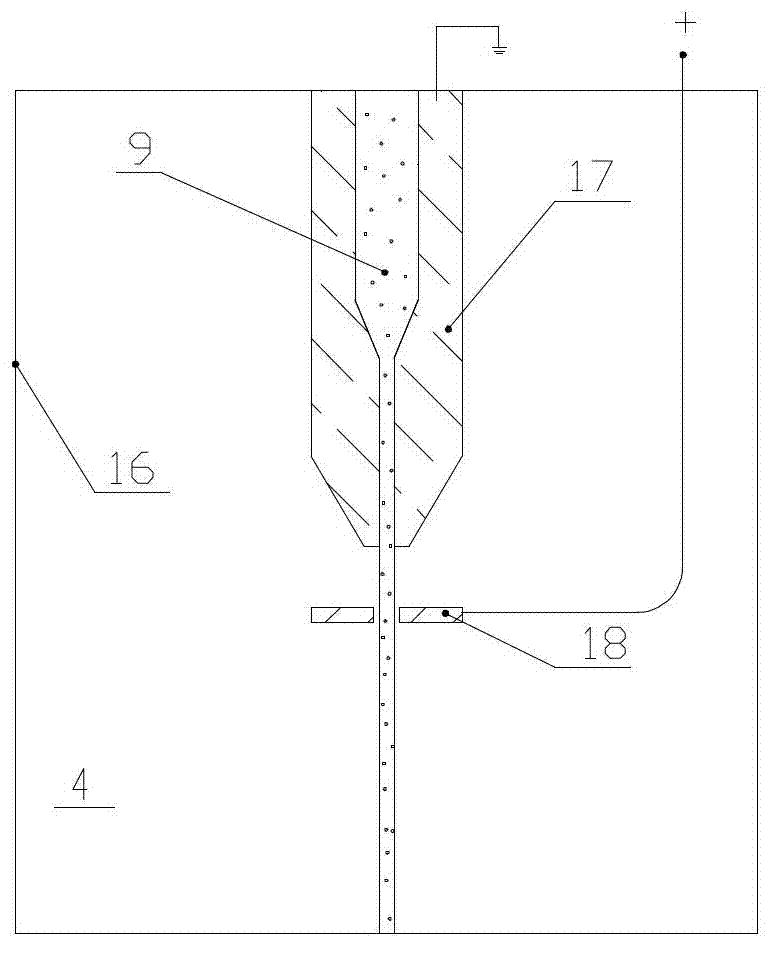

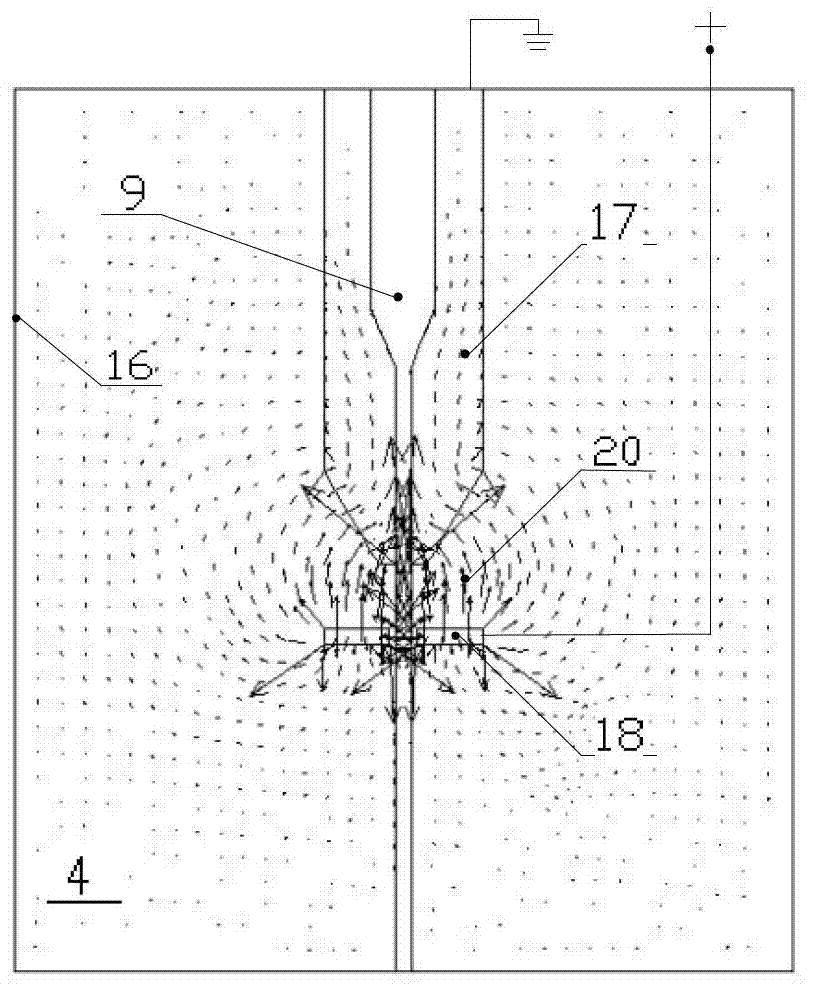

[0032] The implementation of the device of the present invention will be described in further detail below in conjunction with the accompanying drawings. Such as figure 1 , is the schematic structural view of the electrorheological jet polishing device of the present invention, including a working cabin 1, a turntable 2, a machine tool 3, an injection device 4, a filter 5, a stirring box 6, a cooling device 7, a booster device 8, an electric current Polishing liquid 9, workpiece 10, first guide tube 11, second guide tube 12, collimated jet stream 13, waste liquid 14 and third guide tube 15.

[0033] Among them, the machine tool 3 provides precision linear motion axes in the X, Y and Z directions; the spray device 4 is equipped with a nozzle and an electric field generator, which are integrally fixed on the X-axis moving device of the machine tool 3 to realize three-dimensional precise linear motion; The table is installed on the table of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com