Special closing-in machine for high-pressure seamless gas cylinder

A seamless gas cylinder and necking machine technology, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problem of unable to produce steel cylinders of Φ610×12000, and achieve automation of the control process, high production efficiency, and a wide range of processing big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

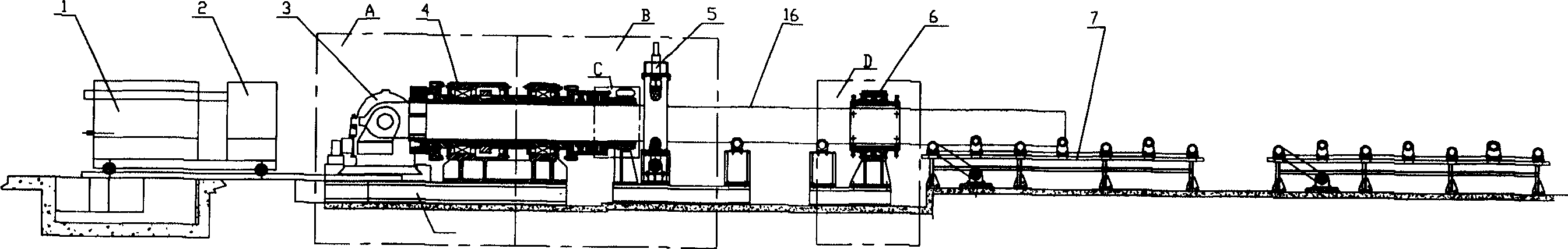

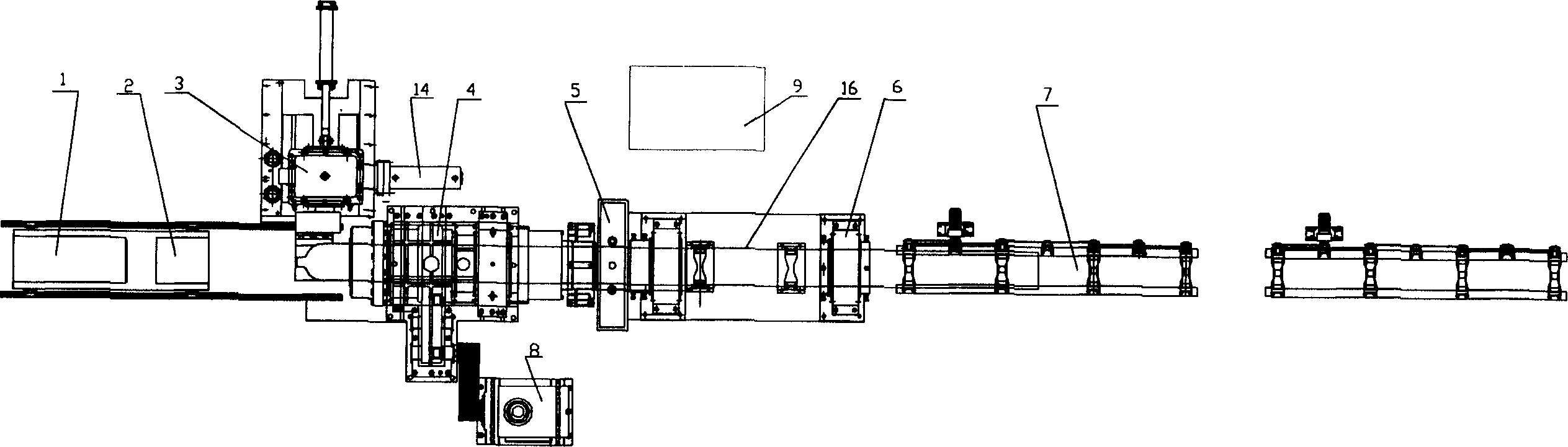

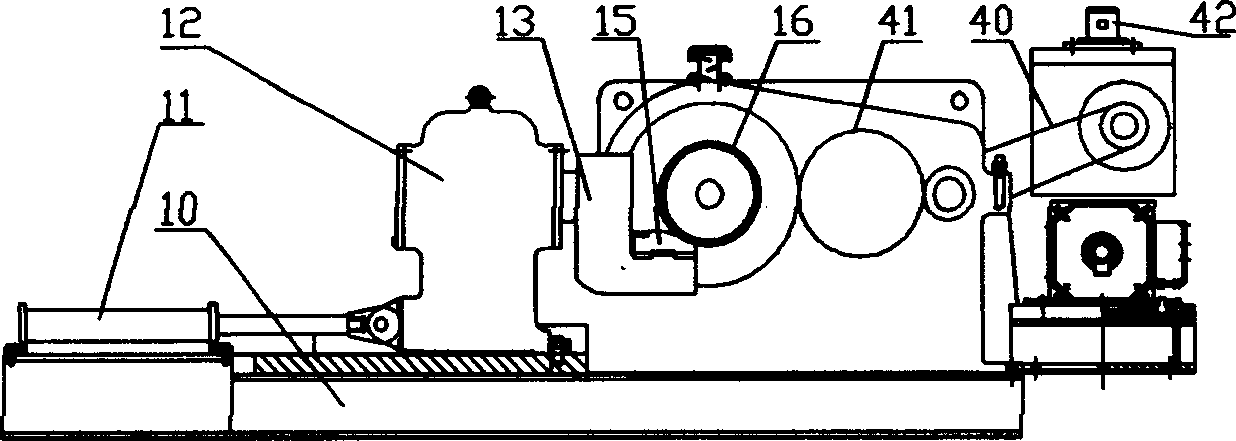

[0017] The present invention includes clamping device 4, feeding roller table 7, power device 8, forming device 3, pressing device 5, auxiliary support 6, intermediate frequency heating furnace 2, hydraulic pressure, lubrication station 9, electric control box 1 and base 10, such as figure 1 , 2 shown. The left end of the hollow main shaft 19 of the clamping device 4 fixes the jaw guide plate 18, and the inner hole wall of the jaw guide plate 18 is evenly distributed with a conical slideway, and each slideway is slidably equipped with a jaw 17 ,Such as Figure 4 shown. Jaw 17 moves to the left to loosen, and moves to the right to clamp, and the right end of jaw 17 is hinged with the left end of hollow pull bar 20 . Pull rod 20 is contained in the inner hole of main shaft 19 with clearance, and its right end is fixed with the piston 24 of oil cylinder 23, as Figure 5 As shown, the left and right chambers of the oil cylinder 23 are connected to the hydraulic pressure and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com