Five-axis controlled motion control mechanism of water cutting head with functions of rotation and swing

A motion control and cutting head technology, applied in metal processing and other directions, can solve the problems of no five-axis control, can not be applied to occasions with cutting bevel requirements, and affect the machining accuracy and efficiency of water jet cutting machines, so as to improve the machining accuracy and efficiency. , The effect of expanding the processing range and high control precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

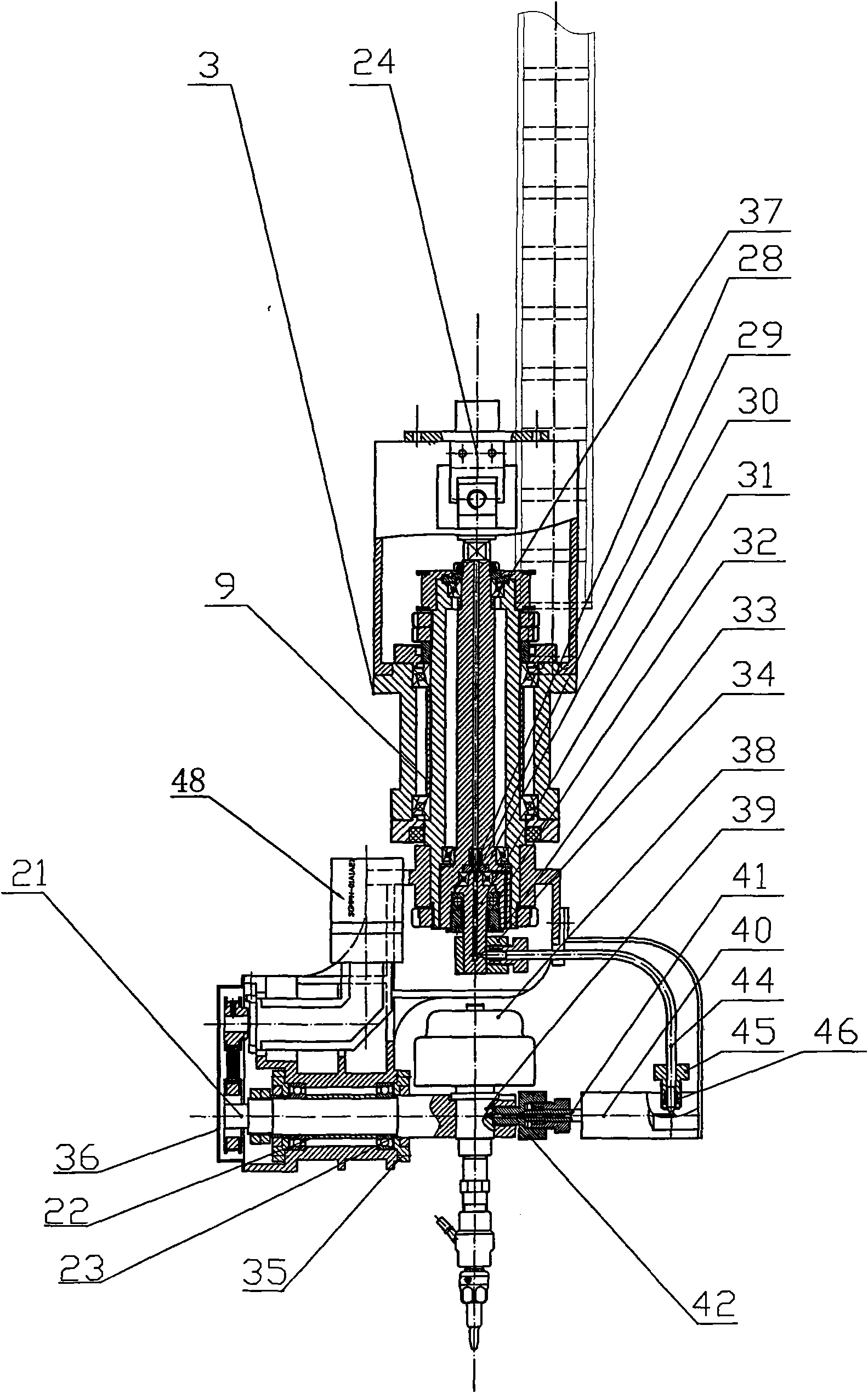

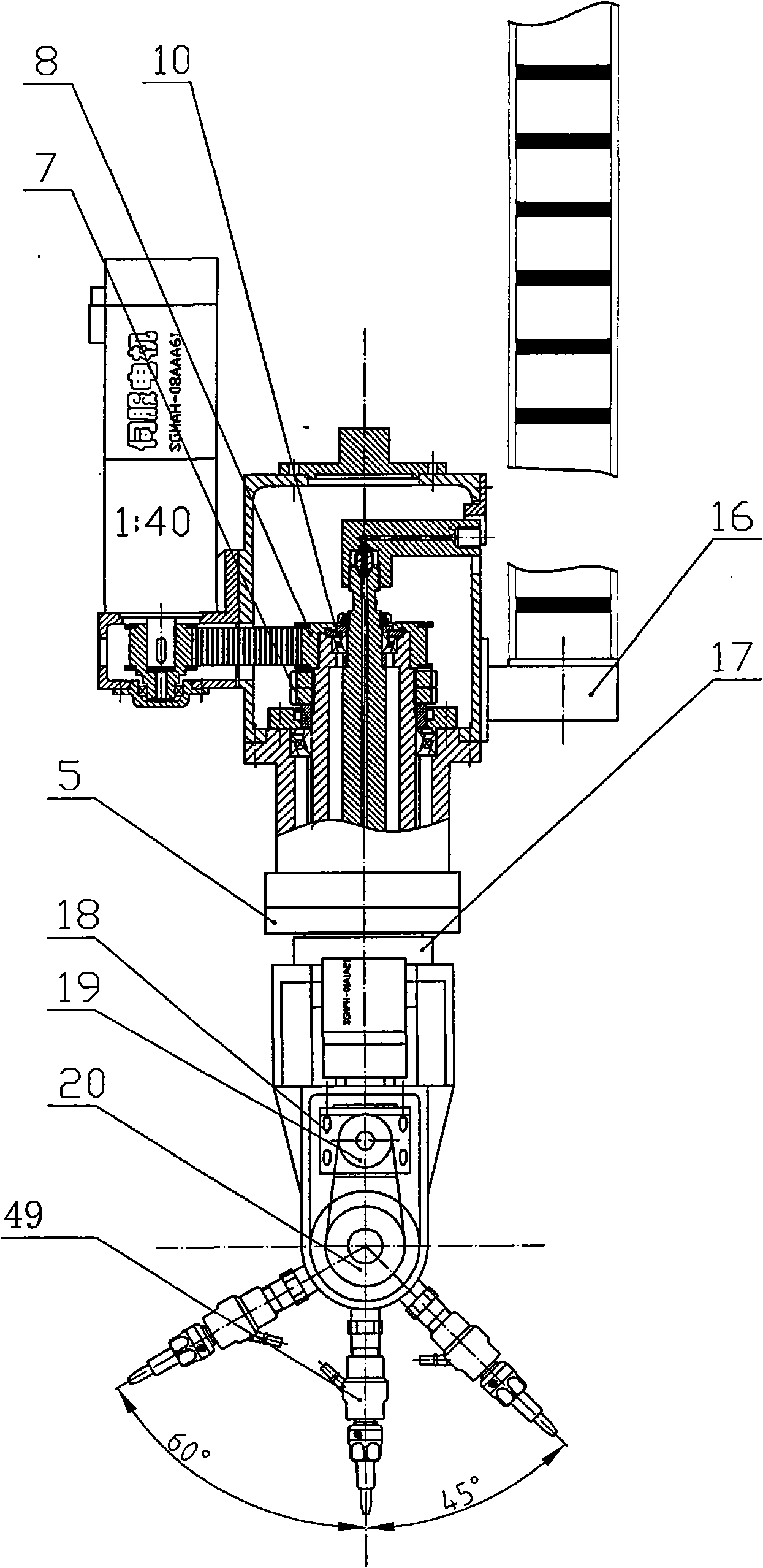

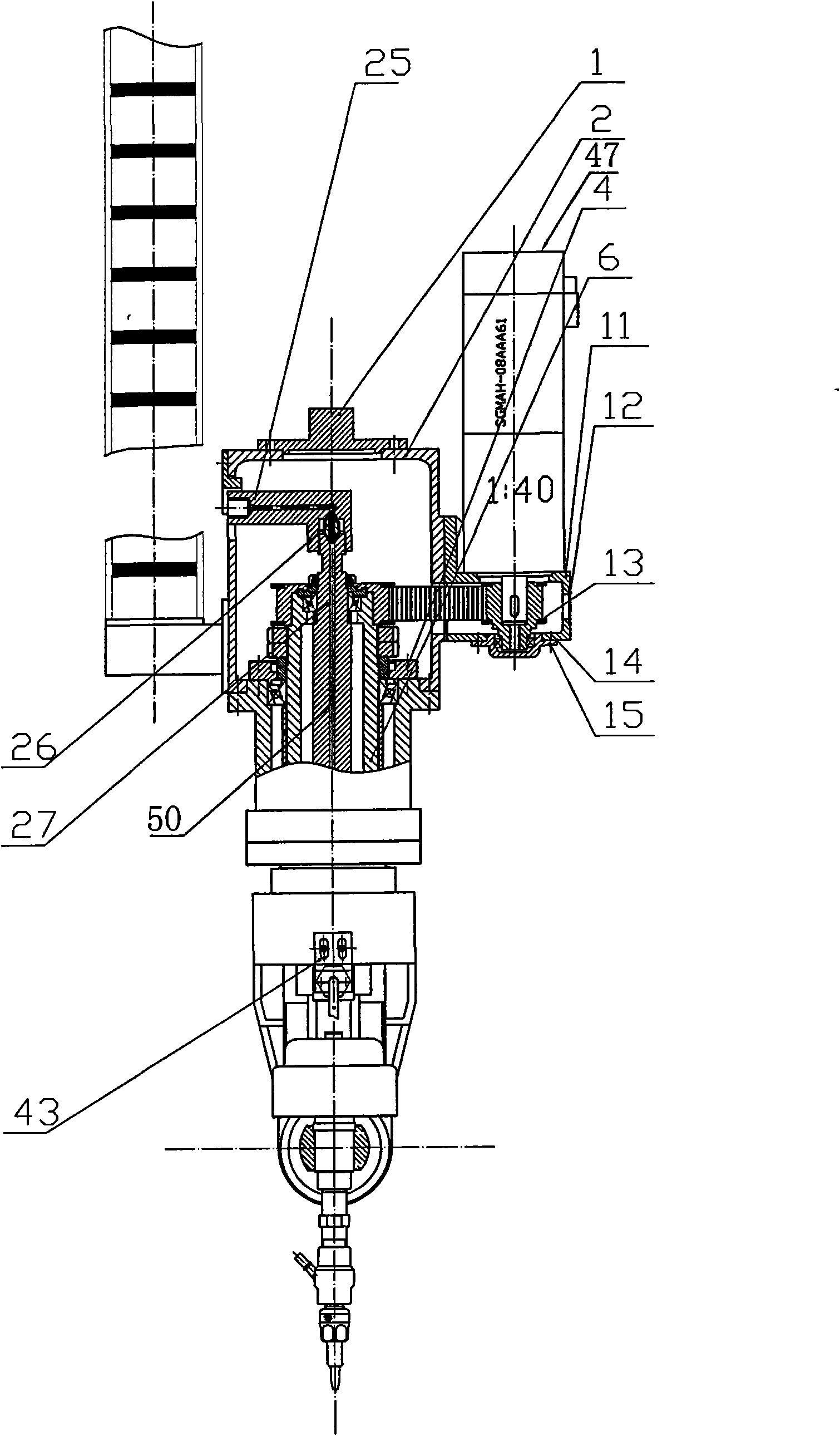

[0017] Such as figure 1 , 2 , 3 shown.

[0018] A five-axis control water cutting head motion control mechanism with rotation and yaw functions, which includes a connecting flange 1, a rotating shaft connecting frame 2, and the rotating shaft connecting frame 2 can move horizontally (that is, in the X direction) through the connecting flange 1 and It is connected with the drive frame that moves in the vertical direction (ie Z direction), and the drive frame is installed on the beam that can move longitudinally (ie Y direction). A rotary motor 47 is installed on the top, and a small synchronous wheel 13 is installed on the output shaft of the rotary motor 47 (servo motor can be used). The small synchronous wheel 13 is connected with the large synchronous wheel 8 by a synchronous belt, and the large synchronous wheel 8 is installed on the rotating shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com