Vacuum system

A vacuum system and vacuum technology, applied in the field of vacuum systems, can solve problems such as the inability to realize small-caliber non-gravity pressurized discharge, unfavorable sewage system pipeline layout and construction, and unsatisfactory suction and discharge forces, etc., to achieve expanded sewage treatment range, improving system reliability, and smooth sewage discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

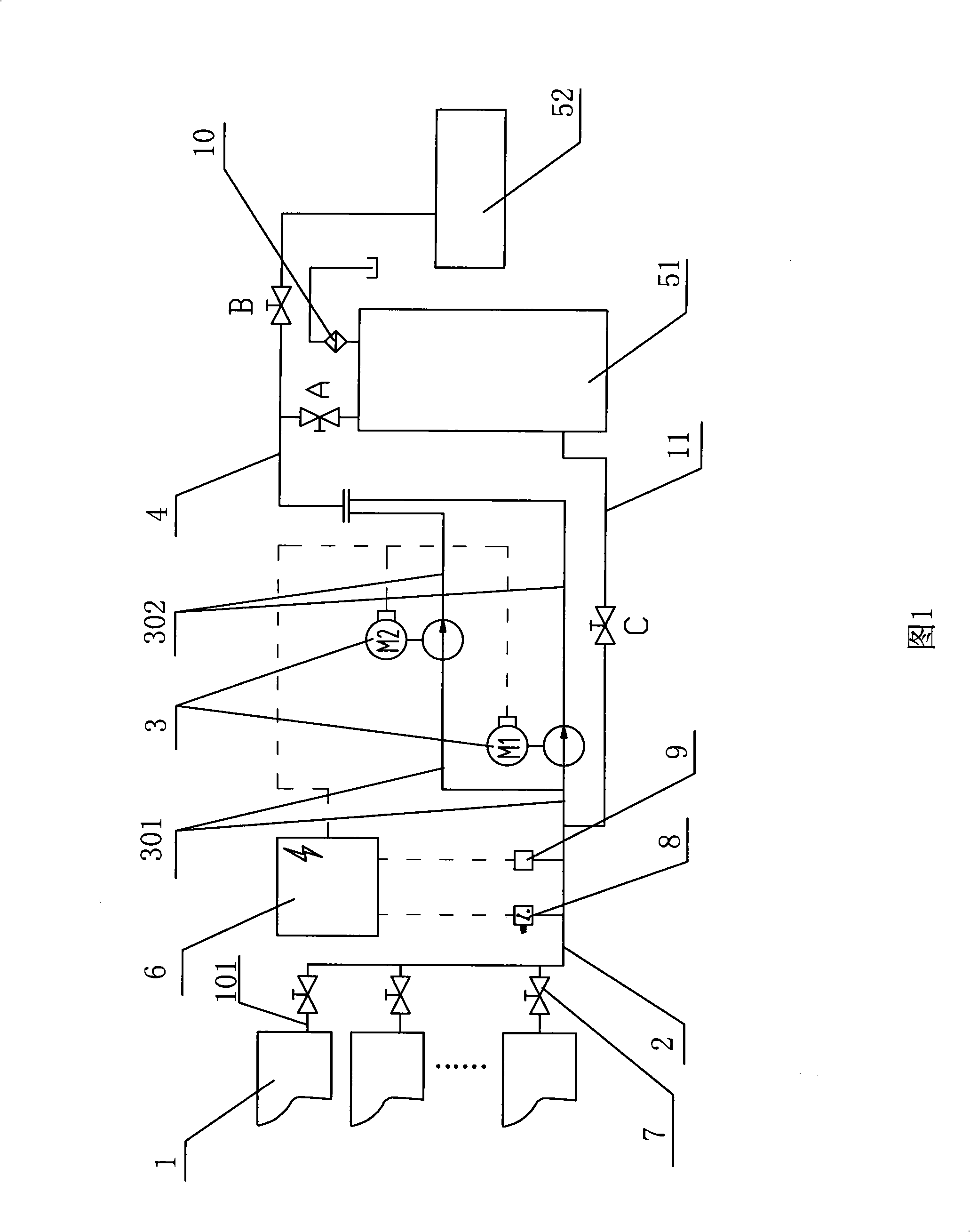

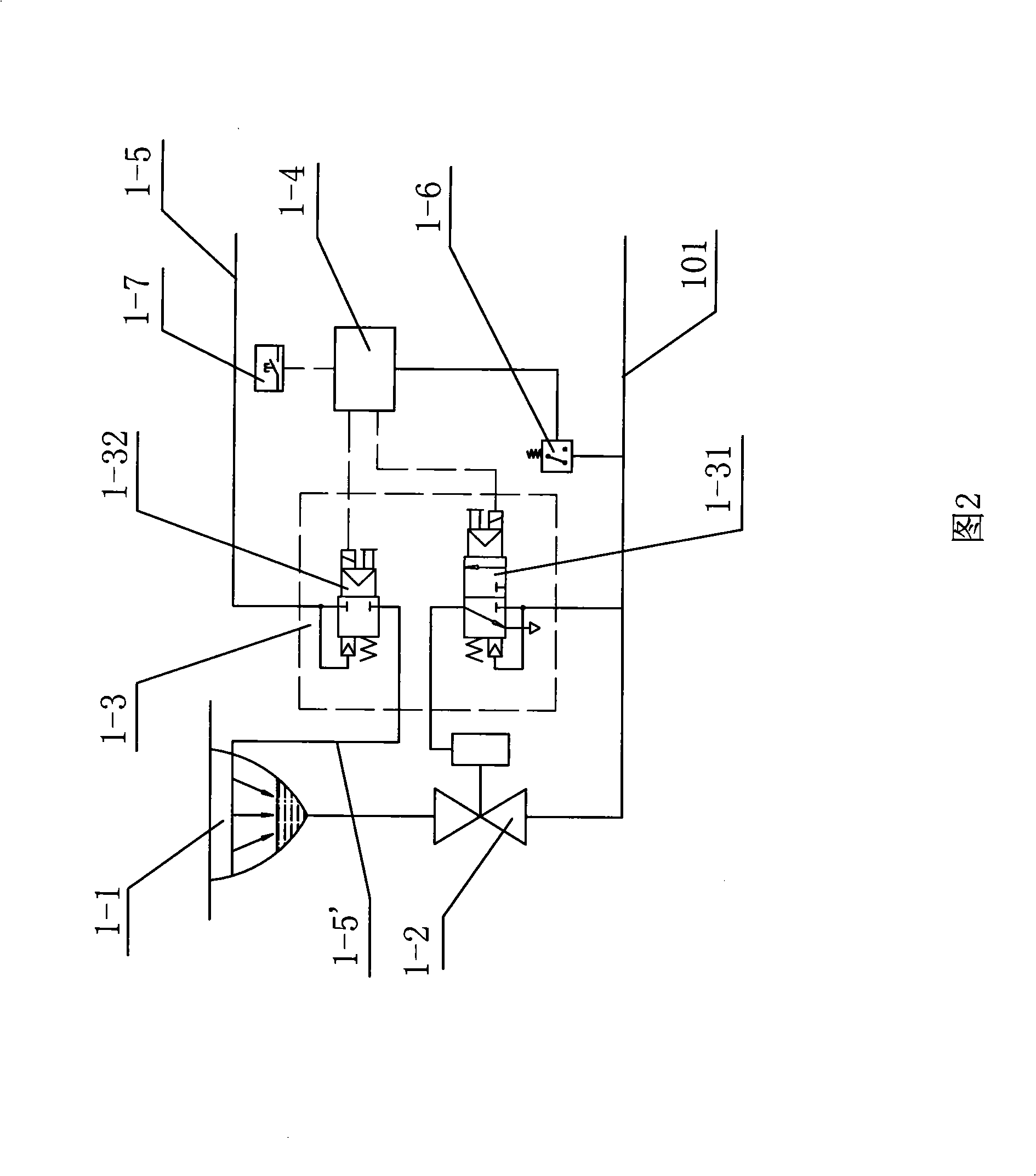

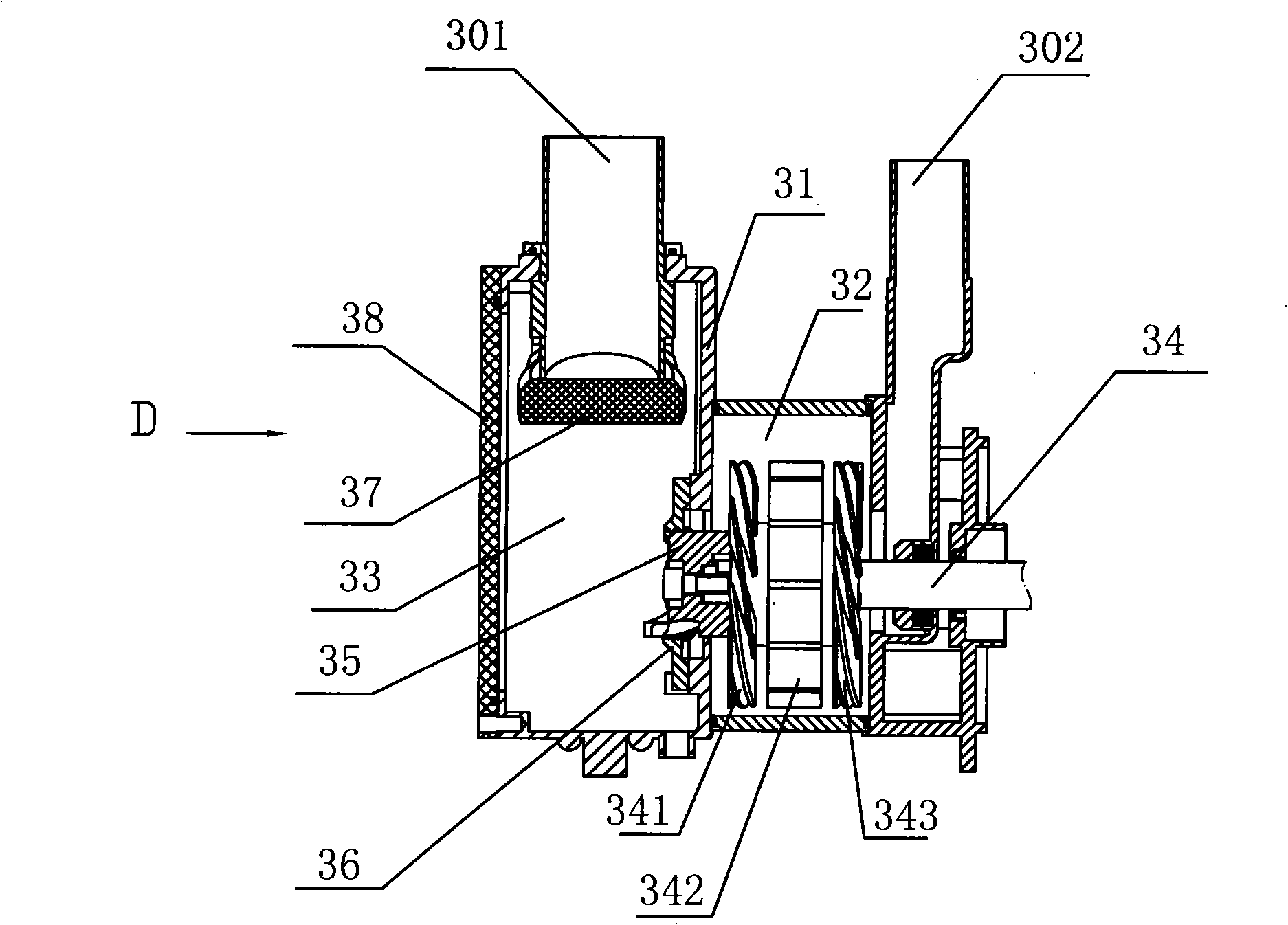

[0027]Embodiment 1: A vacuum system of this embodiment, as shown in FIG. 1 , includes multiple sewage sources 1 , two vacuum conveying pumps 3 , a waste collection place, and a control center 6 . The discharge pipe 101 of each sewage source 1 is connected to the sewage suction pipe 2 through the isolation ball valve 7, and the sewage suction pipe 2 is connected to the inlet pipe 301 of each vacuum conveying pump 3, and the outlet pipe 302 of each vacuum conveying pump 3 is connected to the sewage discharge Pipe 4, sewage pipe 4 is connected to the dirt collection place again. A vacuum pressure switch 8 and a pressure sensor 9 electrically connected to the control center 6 are installed on the sewage suction pipe 2 , and the vacuum delivery pump 3 is also electrically connected to the control center 6 . In the present embodiment, the dirt collection place includes dirt collection equipment 51 and sewage purification equipment or sewer 52, and a conversion ball valve A is instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com