Flat grinder using vacuum chuck

A technology of vacuum suction cup and surface grinder, which is applied in the direction of grinding workpiece supports, etc., can solve the problems of grinding and working of non-metallic workpieces, restricting the grinding and processing of non-metallic workpieces, and reducing the processing range of ordinary surface grinders, so as to achieve the goal of expanding the processing range. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

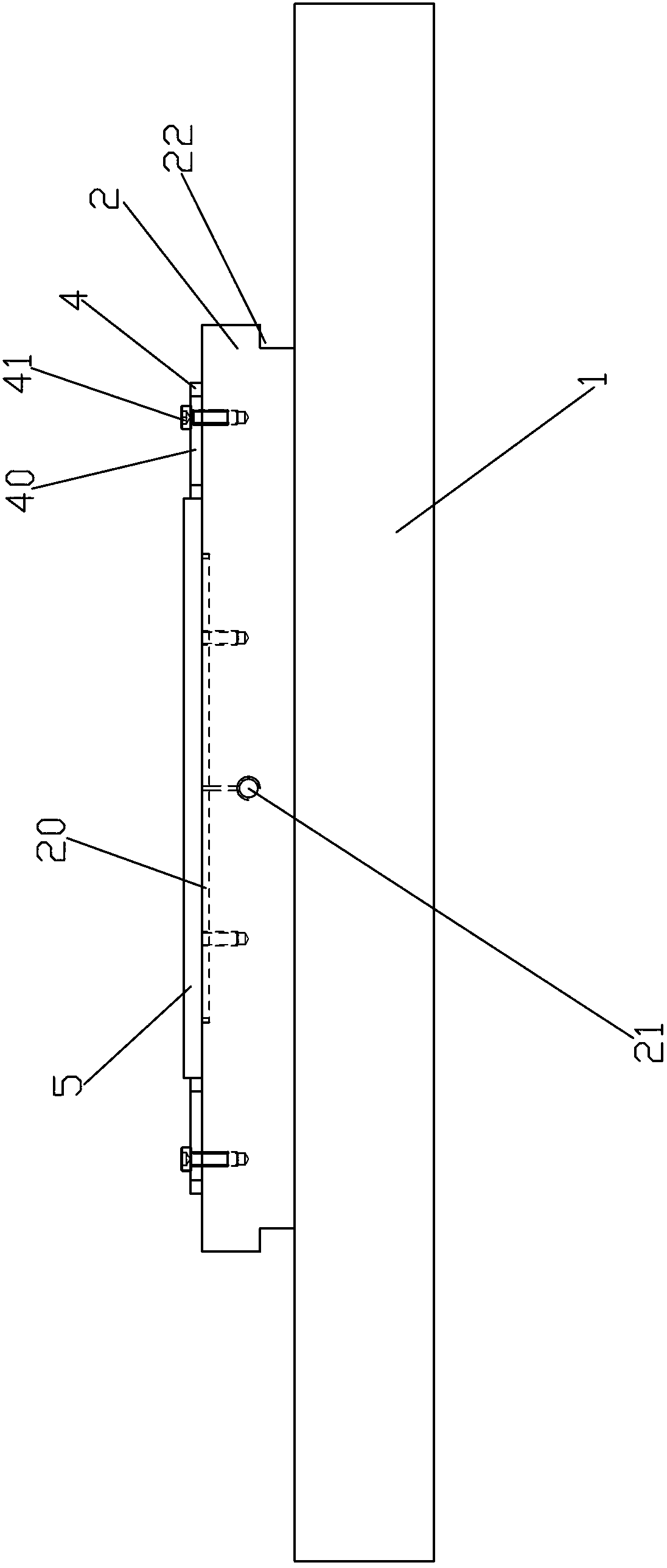

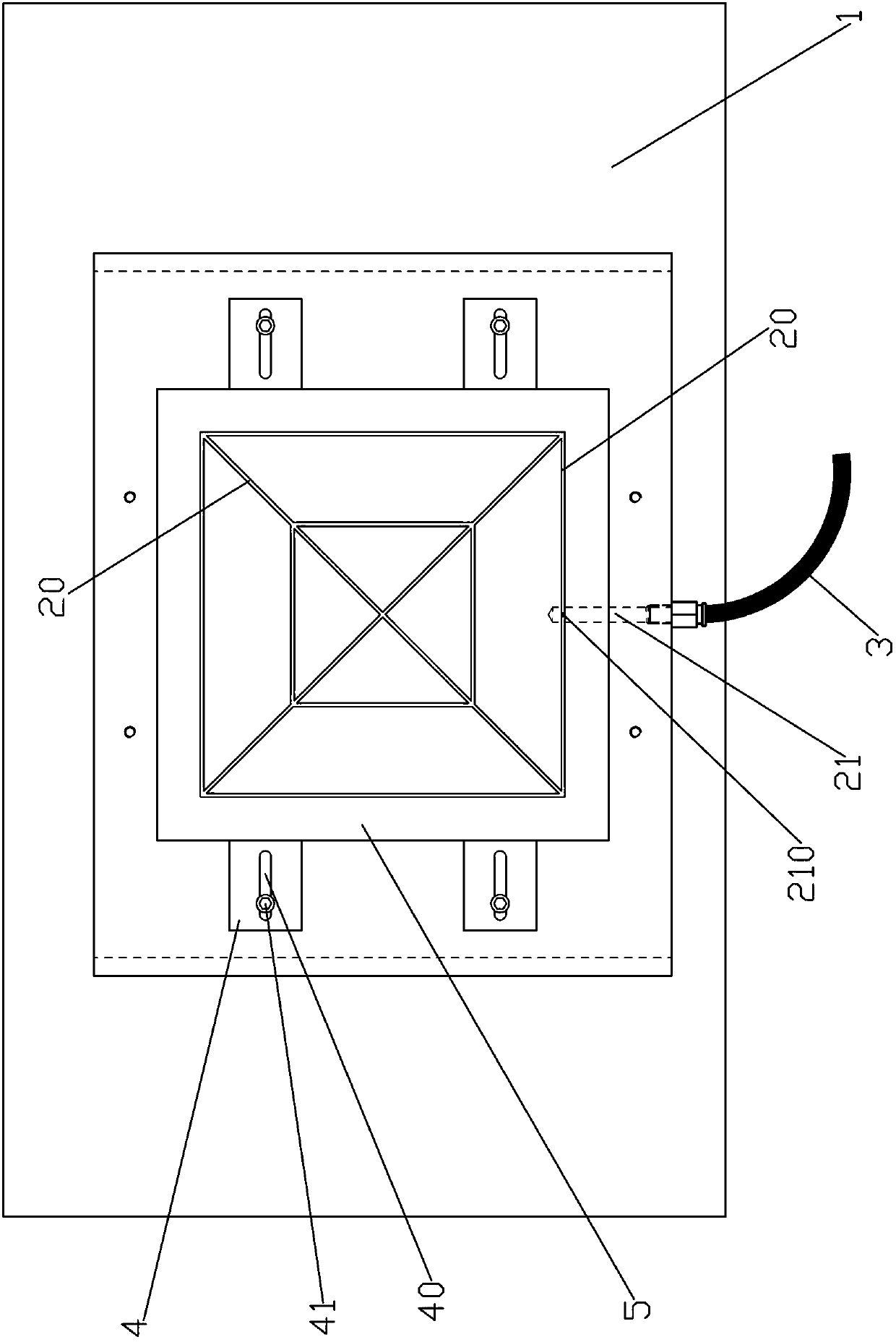

[0015] refer to figure 1 , Fig. 2, a kind of surface grinder that adopts vacuum suction cup, comprises grinder base 1, and described grinder base 1 is fixedly provided with a vacuum suction cup 2 with smooth surface, in order to save material, reduce the weight of vacuum suction cup 2 simultaneously, described The middle and lower parts of the left and right sides of the vacuum chuck 2 are respectively provided with a depression 22; the upper surface of the vacuum chuck 2 is provided with a bare groove 20, that is, when the workpiece 5 is not placed on the upper surface of the vacuum chuck 2, people can directly see it. The groove 20 located on the upper surface of the vacuum chuck 2, here, as a preferred embodiment of the present invention, the groove 20 is preferably designed to include two square ring grooves inside and outside, and a cross groove connecting the opposite corners of the outer square ring groove, so The above-mentioned intersecting groove passes through the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com