Method for preparing adipic acid by oxidizing cyclohexene with air under catalysis of non-metal carbon

A non-metal, cyclohexene technology, applied in chemical instruments and methods, preparation of organic compounds, preparation of carboxylates, etc., can solve the problems of high reaction temperature, long reaction time, easy deactivation, etc. Simple, environmentally friendly system and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

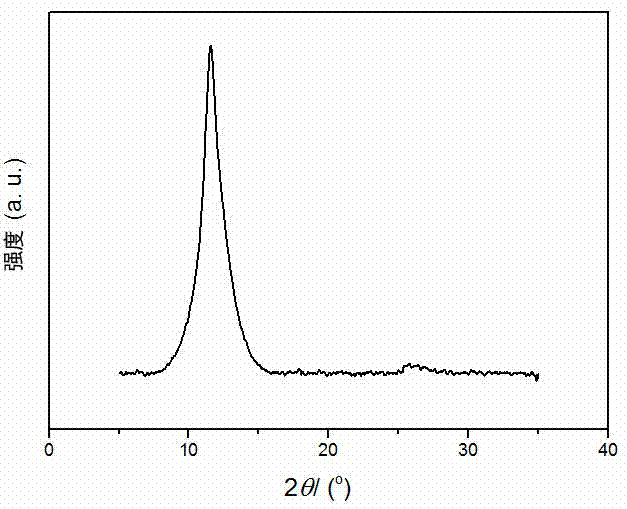

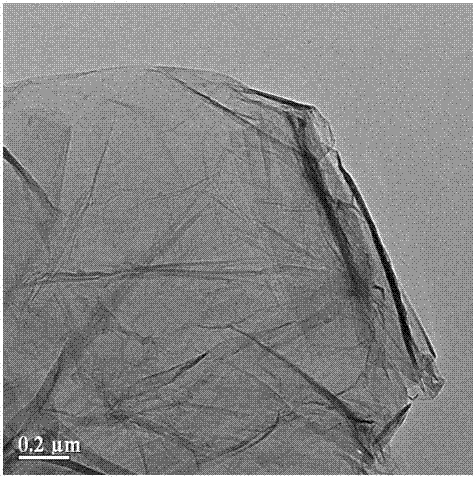

Image

Examples

Embodiment 1

[0027] Example 1: Weigh 0.2 g of acidified carbon nanotubes, put them into a 50 mL stainless steel autoclave filled with 10 mL of deionized water, place the reaction kettle in an ultrasonic instrument, and ultrasonicate for 30 minutes until the graphene oxide is evenly dispersed in water. Add 0.62 mL (0.50 g) of cyclohexene into it, replace the air in the autoclave with oxygen, and then introduce oxygen until the total pressure is 1 MPa. Increase the internal temperature of the autoclave to 80 o C, stirred for 8 hours. After the reaction, cool the autoclave to room temperature, open the autoclave, take out the reaction solution and filter it. The filtrate is separated after standing. The upper oil phase is determined by gas chromatography, and the lower water phase is determined by liquid chromatography to obtain a cyclohexene conversion rate of 32%. , Adipic acid selectivity 17%.

Embodiment 2

[0028] Example 2: Weigh 0.5 g of acidified carbon nanotubes, put them into a 50 mL stainless steel autoclave filled with 10 mL of deionized water, place the reaction kettle in an ultrasonic instrument, and ultrasonicate for 30 minutes until graphene oxide is evenly dispersed in water. Add 0.62 mL (0.50 g) of cyclohexene into it, replace the air in the autoclave with oxygen, and then introduce oxygen until the total pressure is 2 MPa. Increase the internal temperature of the autoclave by 100 o C, stirred for 8 hours. After the reaction, cool the autoclave to room temperature, open the autoclave, take out the reaction solution and filter it, and separate the filtrate after standing. The upper oil phase is determined by gas chromatography, and the lower water phase is determined by liquid chromatography to obtain a cyclohexene conversion rate of 44%. , Adipic acid selectivity 27%.

Embodiment 3

[0029] Example 3: Weigh 0.5 g of acidified carbon nanotubes, put them into a 50 mL stainless steel autoclave filled with 10 mL of deionized water, place the reaction kettle in an ultrasonic instrument, and ultrasonicate for 30 minutes until graphene oxide is evenly dispersed in water. Add 0.62 mL (0.50 g) of cyclohexene into it, replace the air in the autoclave with oxygen, and then introduce oxygen until the total pressure is 2 MPa. Increase the internal temperature of the autoclave to 120 o C, stirred for 8 hours. After the reaction, cool the autoclave to room temperature, open the autoclave, take out the reaction solution and filter it, the filtrate is separated after standing, the upper layer oil phase is measured by gas chromatography, and the lower layer water phase is measured by liquid chromatography to obtain a cyclohexene conversion rate of 56%. , Adipic acid selectivity 40%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com