Process for synthesizing p-aminophenol through nitrobenzene hydrogenation

A technology for p-aminophenol and nitrobenzene, which is applied in the field of catalytic reaction, can solve problems such as filtration separation, loss, etc., and achieves the effects of simple equipment and process, and stable reusable performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

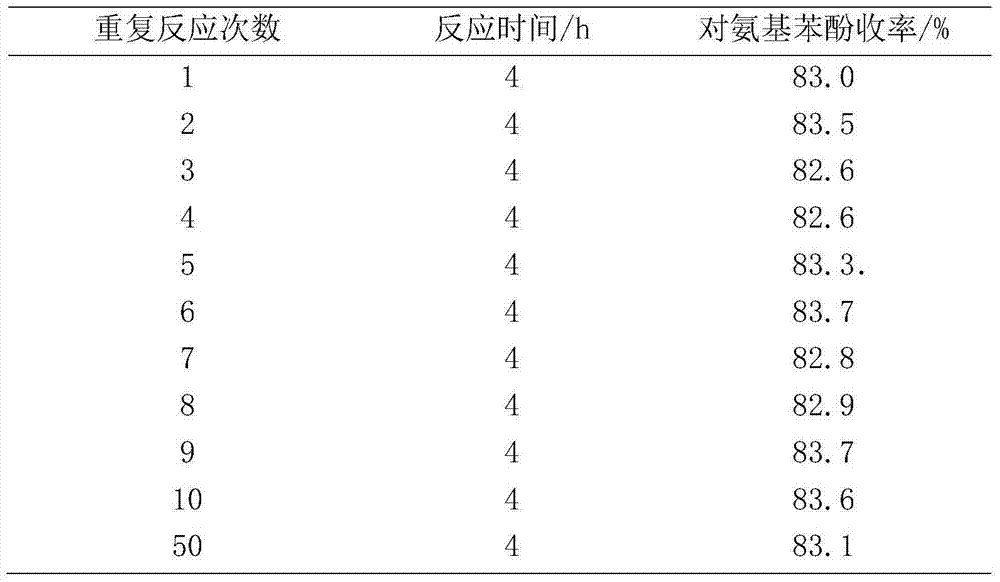

Examples

Embodiment 1

[0023] In the first step, put 1.0g of Pt / C catalyst with 0.1% Pt load and 100g of solvent water into a 200ml tank reactor whose wall material is glass after being calcined at 100°C. A zirconium stirring blade and a thermocouple sleeve, the ratio of the surface area of the metal member in contact with the reaction solution to the volume of the reaction solution is 0.1cm 2 / 1cm 3 ;

[0024] In the second step, in the above reactor, with N 2 After replacing the air for 8 to 12 minutes, pass H at a temperature of 80oC 2 , to H 2 The partial pressure is 0.1MPa, and the treatment time is 1 hour;

[0025] In the third step, after the treatment in the second step is completed, the reactor is lowered to room temperature, the catalyst is filtered, and the filtered catalyst can be used for related catalytic reactions after drying, and the filtrate can be reused as a treatment liquid for the next treatment process;

[0026] In the fourth step, the filtrate obtained by filtering in ...

Embodiment 2

[0031] In the first step, 0.4 g of Pt / Al with a Pt loading of 0.1% after calcination at 600 °C 2 0 3 Catalyst, 5g acetic acid, and 100g solvent water are put into a zirconium material tank reactor. The reactor is equipped with a stirring paddle, a thermocouple sleeve and a metal coil of the same material. The ratio of the surface area to the volume of the reaction solution is 2 cm 2 / 1cm 3

[0032] In the second step, in the above reactor, with N 2 After replacing the air for 8 to 12 minutes, pass H at a temperature of 180oC 2 , to H 2 The partial pressure is 0.5MPa, and the treatment time is 10 hours;

[0033] In the third step, after the treatment in the second step is completed, the reactor is lowered to room temperature, the catalyst is filtered, and the filtered catalyst can be used for related catalytic reactions after drying, and the filtrate can be reused as a treatment liquid for the next treatment process;

[0034] In the fourth step, the filtrate obtained by fi...

Embodiment 3

[0039] In the first step, 5 g of Pt / Al with a Pt loading of 0.01% after calcination at 300 °C 2 0 3 Catalyst, 0.1g citric acid, and 100g solvent water are put into a zirconium material tank reactor. The reactor is equipped with a stirring paddle, a thermocouple sleeve and a metal coil of the same material. The metal components and the reaction The ratio of the surface area in contact with the liquid to the volume of the reaction liquid is 5 cm 2 / 1cm 3 ;

[0040] In the second step, in the above reactor, with N 2 After replacing the air for 8-12 minutes, pass H at a temperature of 120oC 2 , to H 2 The partial pressure is 0.2MPa, and the treatment time is 4 hours;

[0041] In the third step, after the treatment in the second step is completed, the reactor is lowered to room temperature, the catalyst is filtered, and the filtered catalyst can be used for related catalytic reactions after drying, and the filtrate can be reused as a treatment liquid for the next treatment pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com