Patents

Literature

36results about How to "Stable and reusable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of metal-base ceramic composite filter membrane

ActiveCN102500245AThe preparation process is easy to operateReasonable designSemi-permeable membranesAnodic oxidationComposite filter

The invention discloses a preparation method of a metal-base ceramic composite filter membrane. The method includes steps: firstly, uniformly coating powder on the surface of a porous matrix, and obtaining a porous metal membrane layer by means of sintering; secondly, soaking the porous metal membrane layer into electrolyte to be anodized and obtaining a transition layer; thirdly, adding oxide powder into dispersing agent to obtain coating liquid; fourthly, coating the coating liquid onto the transition layer and sintering the transition layer after the transition layer is dried; and fifthly,repeating the fourth step for a product after being sintered until a porous ceramic filtering membrane with the thickness ranging from 2mum to 80mum is obtained, and obtaining the metal-base ceramic composite filtering membrane. The problem that bonding is not firm enough when metal and ceramic are compounded is resolved, the effective transition layer is formed on the metal matrix, so that a ceramic layer is firmly bonded with the metal matrix, processability of the prepared composite filter membrane is good, and the composite filter membrane can be used for preparing filtering devices in various shapes, simultaneously, has excellent chemical attack resistance, is high in pressure resistance and stable in repeatability, and can be used as a key component for micro-nano filtering and separating.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

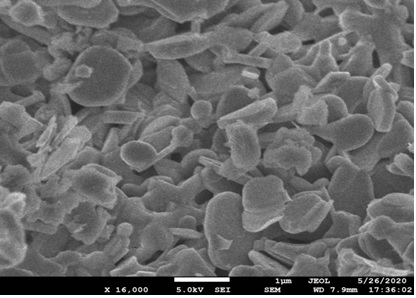

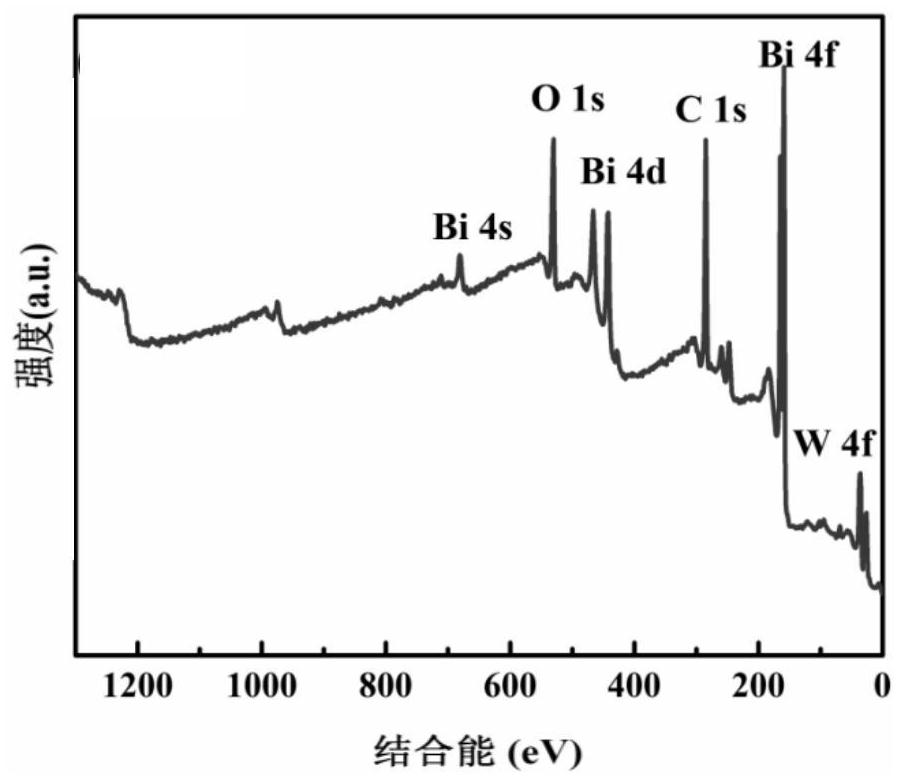

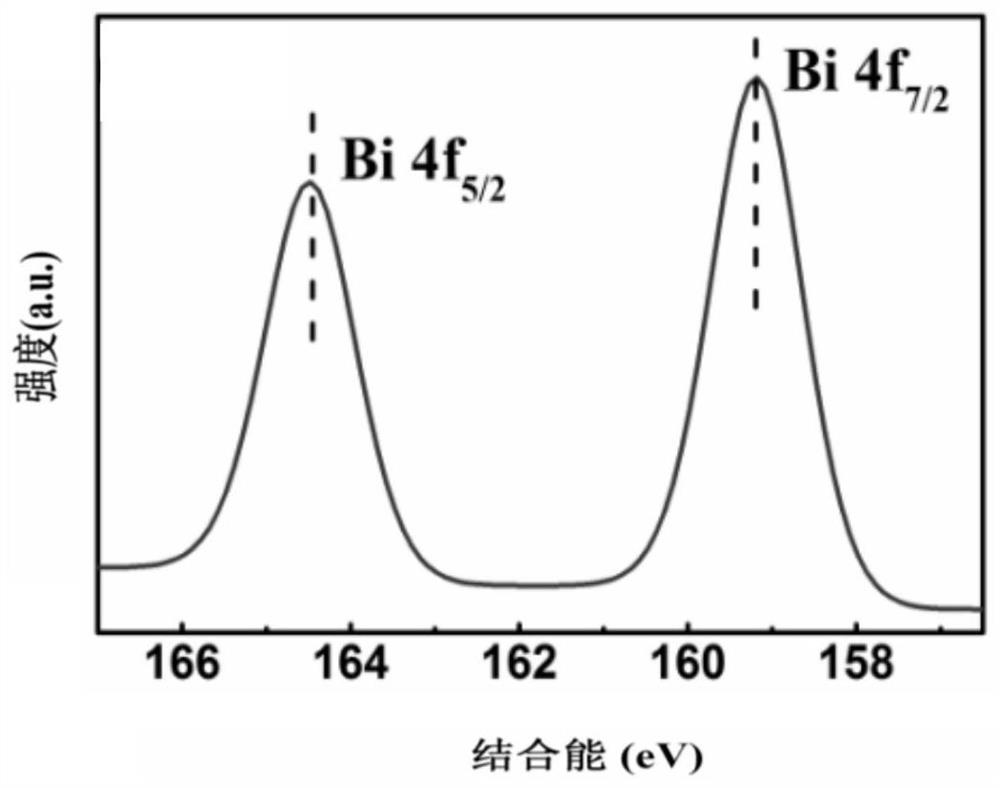

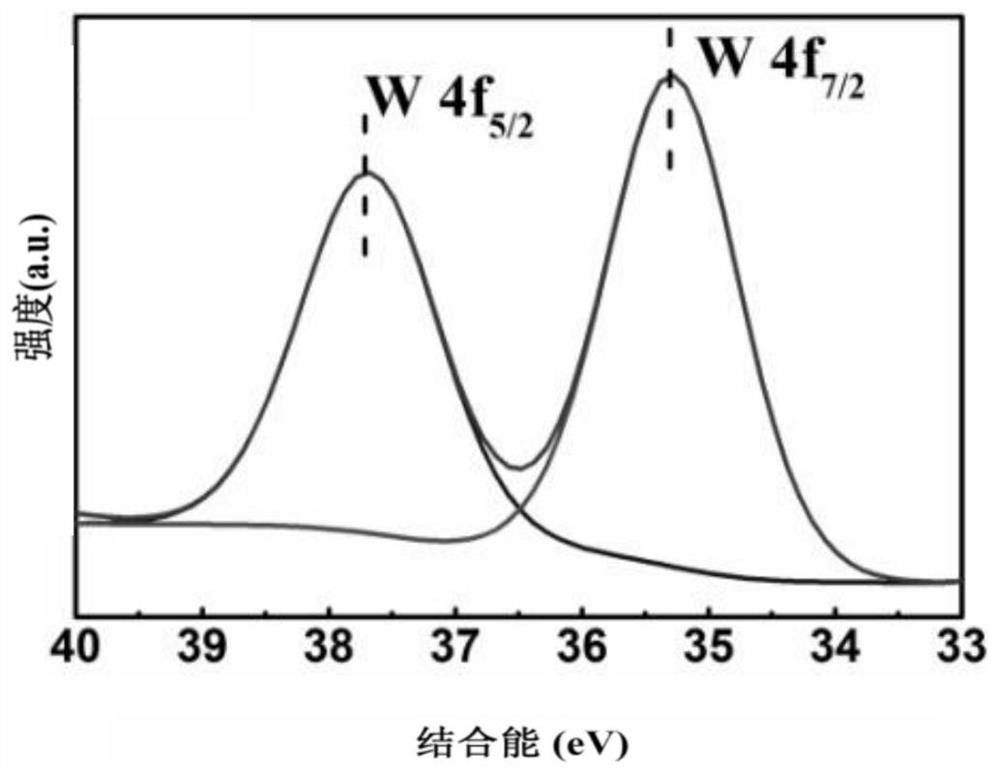

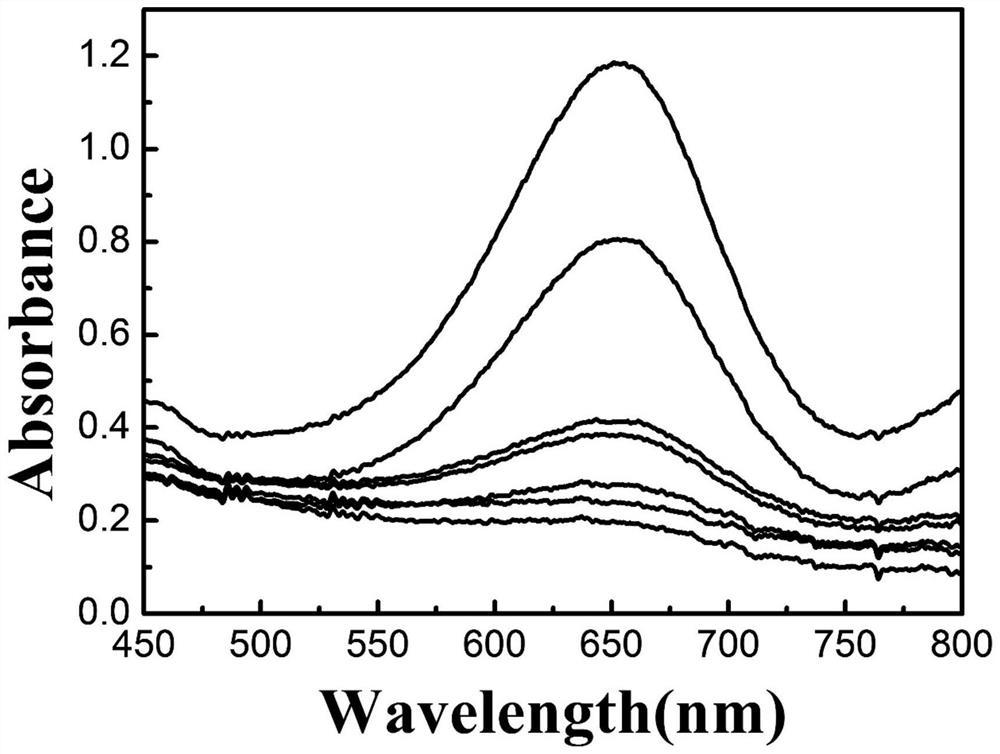

Graphene quantum dots-bismuth tungstate composite photocatalyst and preparation method thereof

InactiveCN108579727AImprove light utilizationReduce recombination rateWater/sewage treatment by irradiationWater treatment compoundsTungstateCrystallinity

The invention discloses a graphene quantum dots-bismuth tungstate composite photocatalyst and a preparation method thereof. According to the composite photocatalyst, bismuth tungstate is used as a photocatalyst, and graphene quantum dots are loaded on bismuth tungstate. The preparation method comprises the following steps: carrying out ultrasonic mixing on a graphene quantum dots solution, sodiumtungstate and deionized water, and then adding cetyl trimethyl ammonium bromide to obtain a solution A; dissolving bismuth nitrate in acetic acid to prepare a solution B, slowly adding the solution Binto the solution A and stirring to obtain a precursor suspension; transferring the precursor suspension into a microwave reaction instrument to carry out a microwave reaction, centrifuging the suspension and drying to prepare a graphene quantum dots-modified bismuth tungstate composite photocatalyst. The composite photocatalyst has good degree of crystallization, uniform morphology, has high photocatalytic activity, strong light absorption capability and high light-generated electron-cavity separation efficiency, and is safe and stable. The technology is simple, reaction conditions are mild and easy to control. The graphene quantum dots-bismuth tungstate composite photocatalyst is easy for industrial production and has good industrial application prospect.

Owner:XIANGTAN UNIV

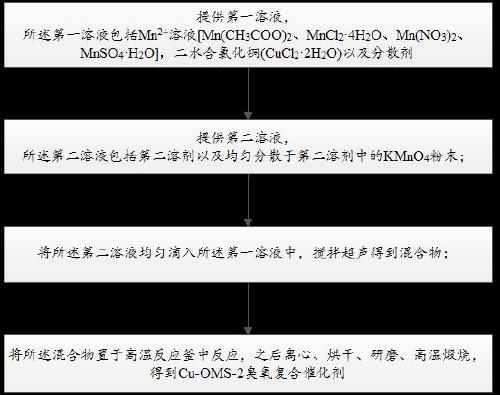

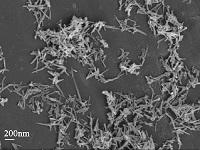

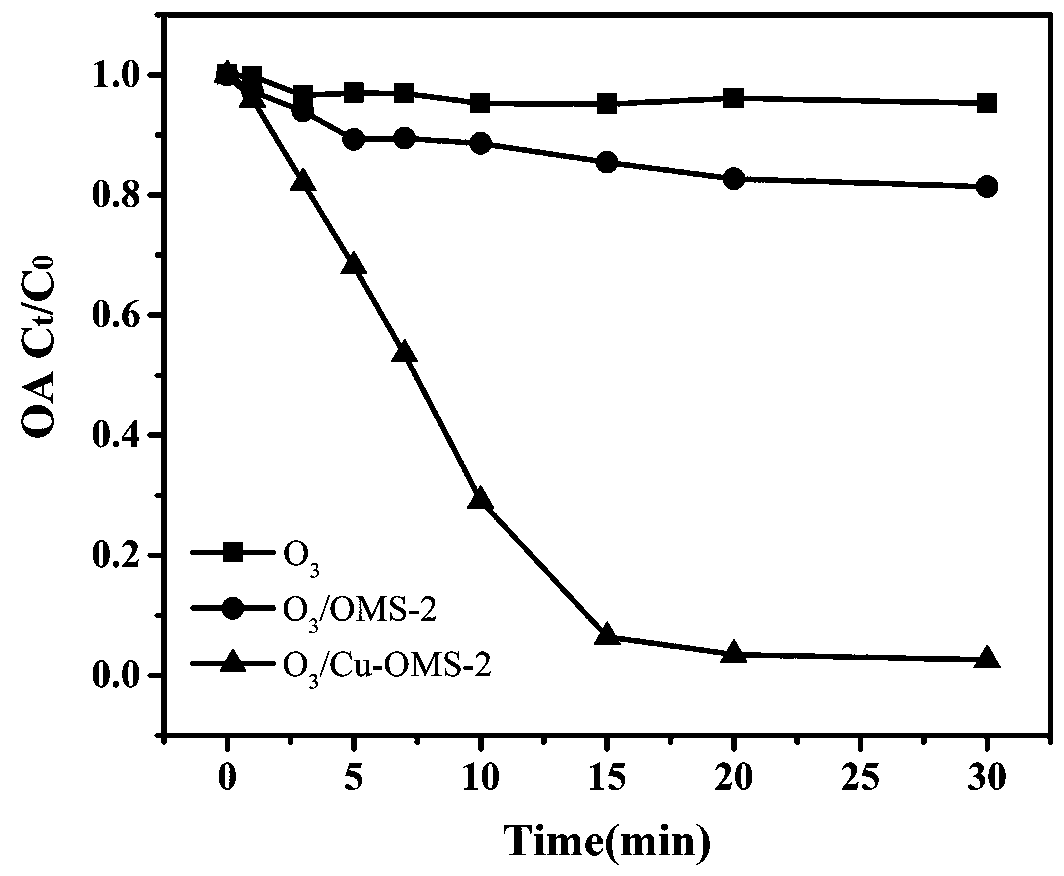

Preparation method and application of rod-like ozone catalyst Cu-OMS-2

InactiveCN110314689APromote degradationGood removal effectWater contaminantsCatalyst activation/preparationMANGANESE ACETATEAcetic acid

The invention provides a preparation method and application of a rod-like ozone catalyst Cu-OMS-2. The preparation method includes: providing a first solution, wherein the first solution comprises a Mn<2+> solution [such as manganese acetate (Mn(CH3COO)2), manganese chloride (MnCl2 4H2O), manganese nitrate (Mn(NO3)2) and manganese sulfate MnSO4 H2O], copper chloride dihydrate (CuCl2 2H2O) and a dispersing agent; providing a second solution, wherein the second solution comprises a second solvent and potassium permanganate (KMnO4) powder evenly dispersed in the second solvent; dropwise adding the second solution into the first solution, and stirring and performing ultrasonic treatment to obtain a mixture; placing the mixture into a high-temperature reaction kettle to perform reaction, centrifuging, drying, grinding, and calcining at high temperature to obtain the Cu-OMS02 ozone compound catalyst. Cu<2+> is doped into an OMS-2 crystal structure and then used for ozone catalysis, metal iondissolution after traditional metal catalyst reaction is lowered effectively, and catalyst activity and stability are increased.

Owner:WUHAN TEXTILE UNIV

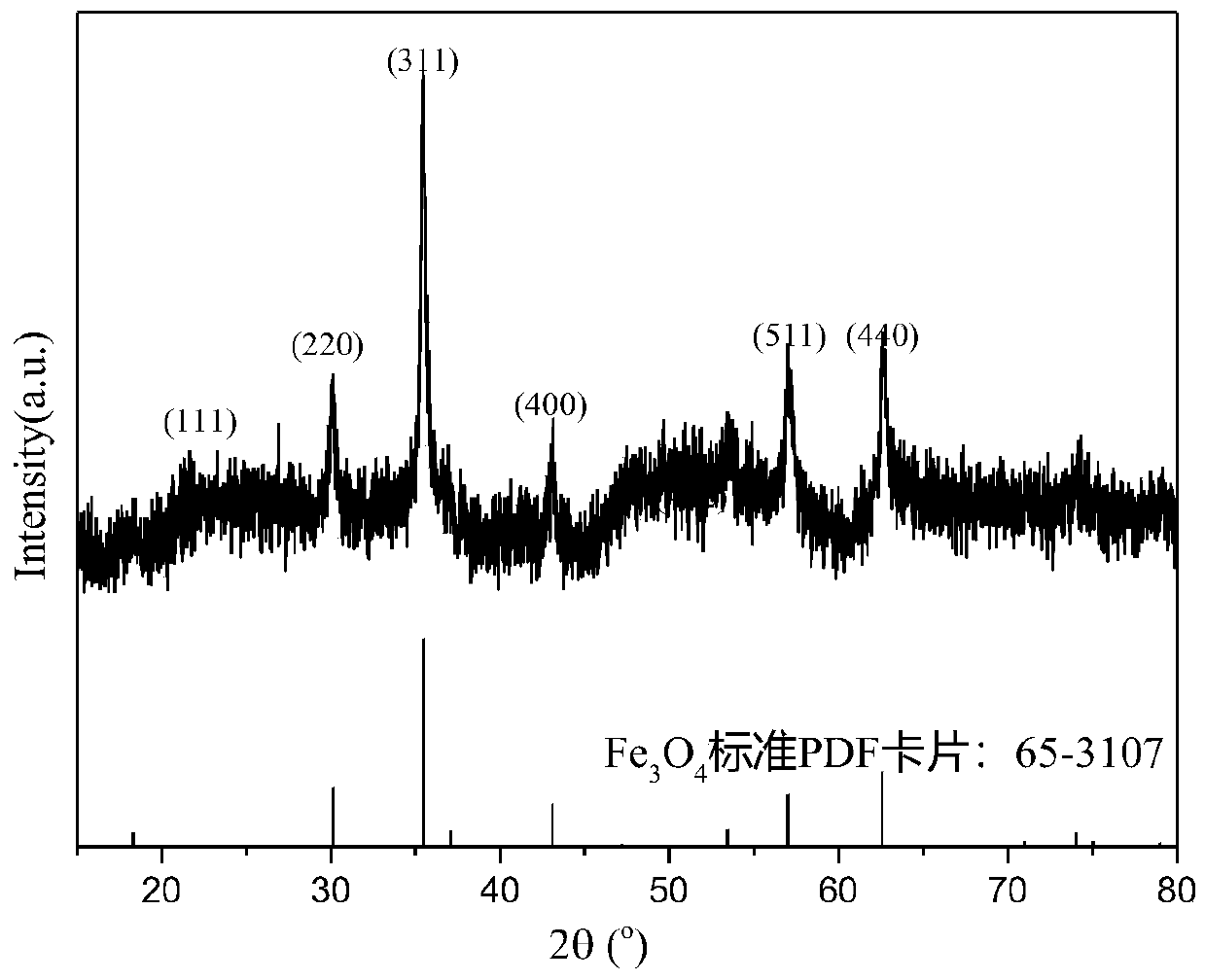

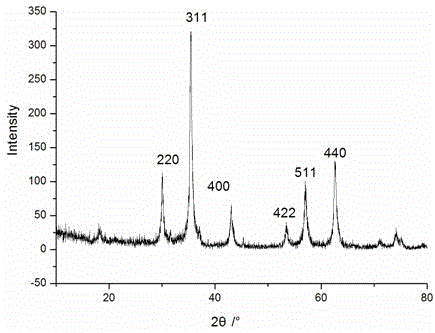

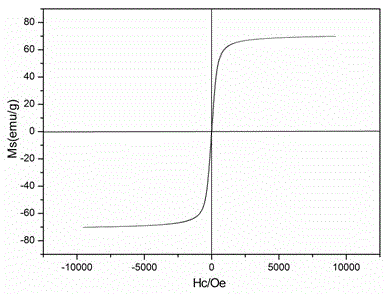

Titanium modified Fe3O4 magnetic nano-particle, preparation method and application thereof

InactiveCN110075846ARapid hydrolysisGreen environmental protection equipment requirementsWater treatment compoundsWater contaminantsMagnetite NanoparticlesSolvent

The invention provides a titanium modified Fe3O4 magnetic nano-particle, a preparation method and the application thereof. The preparation method specifically comprises the following steps: in a eutecticevaporate solvent of choline chloride and urea, taking ferrite as an iron source, tetrabutyl titanate as a titanium source and air as an oxidizing agent, and using a precipitation oxidization process to synthesize the titanium modified Fe3O4 magnetic nano-particle in one step. According to the preparation method provided by the invention, the obtained material has excellent catalytic degradation capacity (for example, under the conditions of room temperature and neutral pH, the color removal rate for a 0.01 mmol / L methylene blue solution within 2h reaching 93.8%, and the removal rate for a20 mg / L Ciprofloxacin solution reaching 96.5%) for organic waste water, is easy for magnetic separation recycle and stable in reuse performance, and is a novel magnetic environmentally-friendly material with low cost, quick and convenient operation, obvious effect and wide application prospect.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Preparation method for nano multihole copper film

The invention discloses a preparation method for a nano multihole copper film. The preparation method comprises the following steps of 1, dissolving polyvinyl butyral into an organic solvent to obtain an organic cementing solution, 2, adding the organic cementing solution into copper powder, and uniformly stirring the copper powder and the organic cementing solution to obtain copper powder slurry, and 3, uniformly coating the copper powder slurry on a carrier, and performing drying and thermal treatment to obtain the nano multihole copper film attached to the carrier, or uniformly coating the copper powder slurry on the carrier, performing drying and thermal treatment, and corroding the carrier by adopting hydrochloric acid to obtain the non-supported nano multihole copper film. According to the preparation method, raw materials are readily available; a preparation process is simple; the prepared nano multihole copper film is high in processibility, can be made into filtering devices of various shapes, is stable in reusability and can be used as a key component for micro-nano size filtration and separation. By the method, the nano multihole copper films of any shape on a load or the surface of the carrier or the non-supported nano multihole copper films can be obtained by controlling the shape of the carrier.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Organic heteropoly hybrid catalyst for esterification reaction and preparation method thereof

InactiveCN102698802AThe synthesis process is simpleHigh yieldOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsProtonationPhosphomolybdic acid

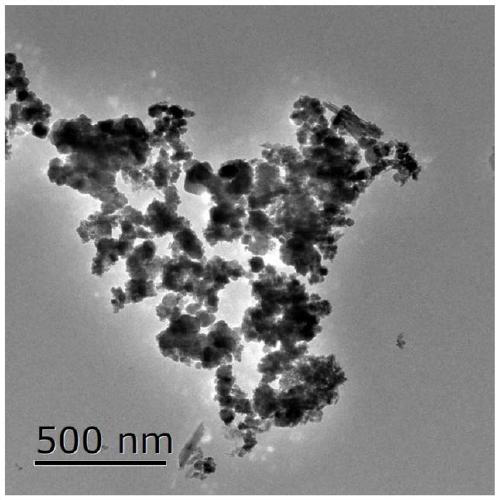

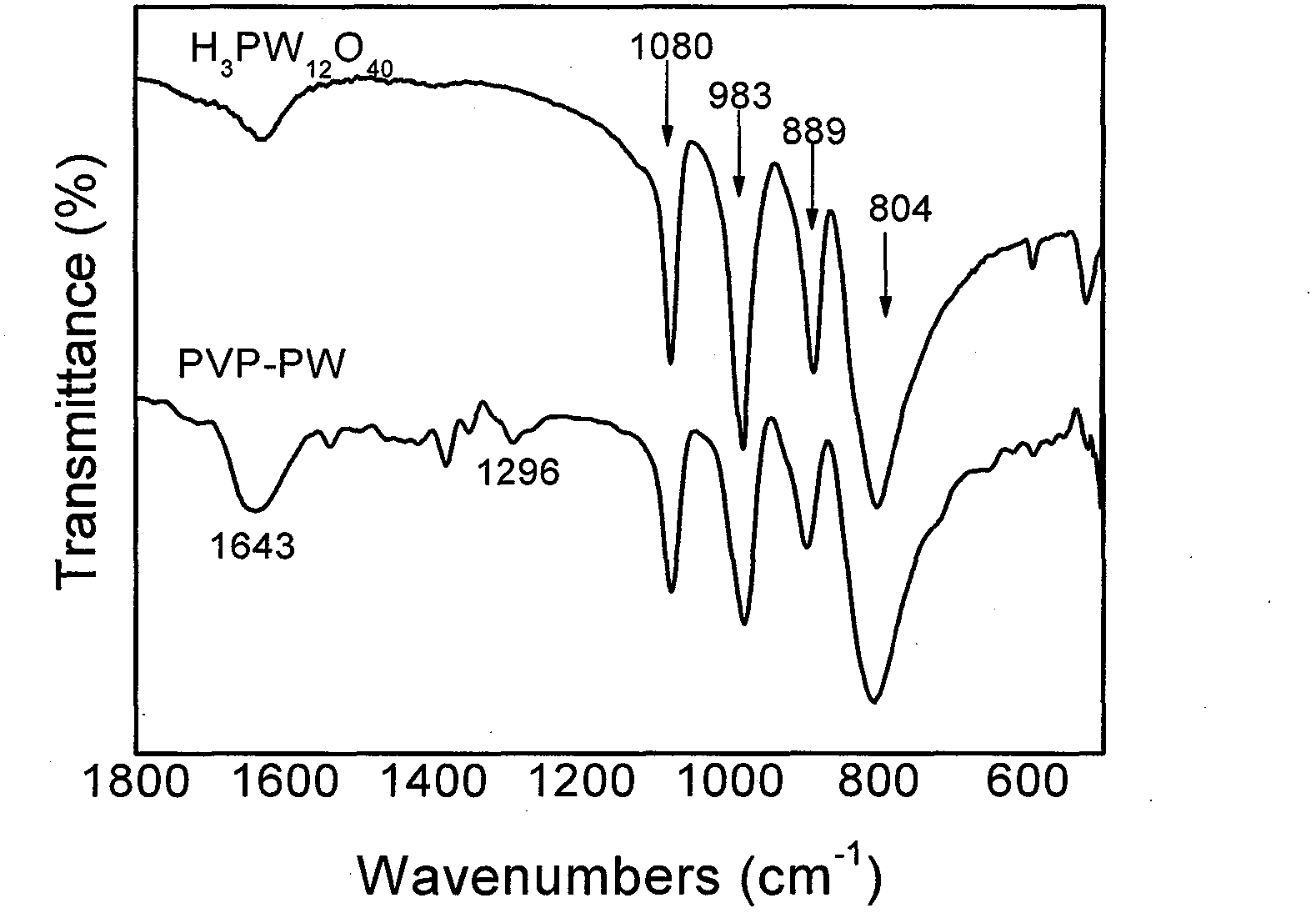

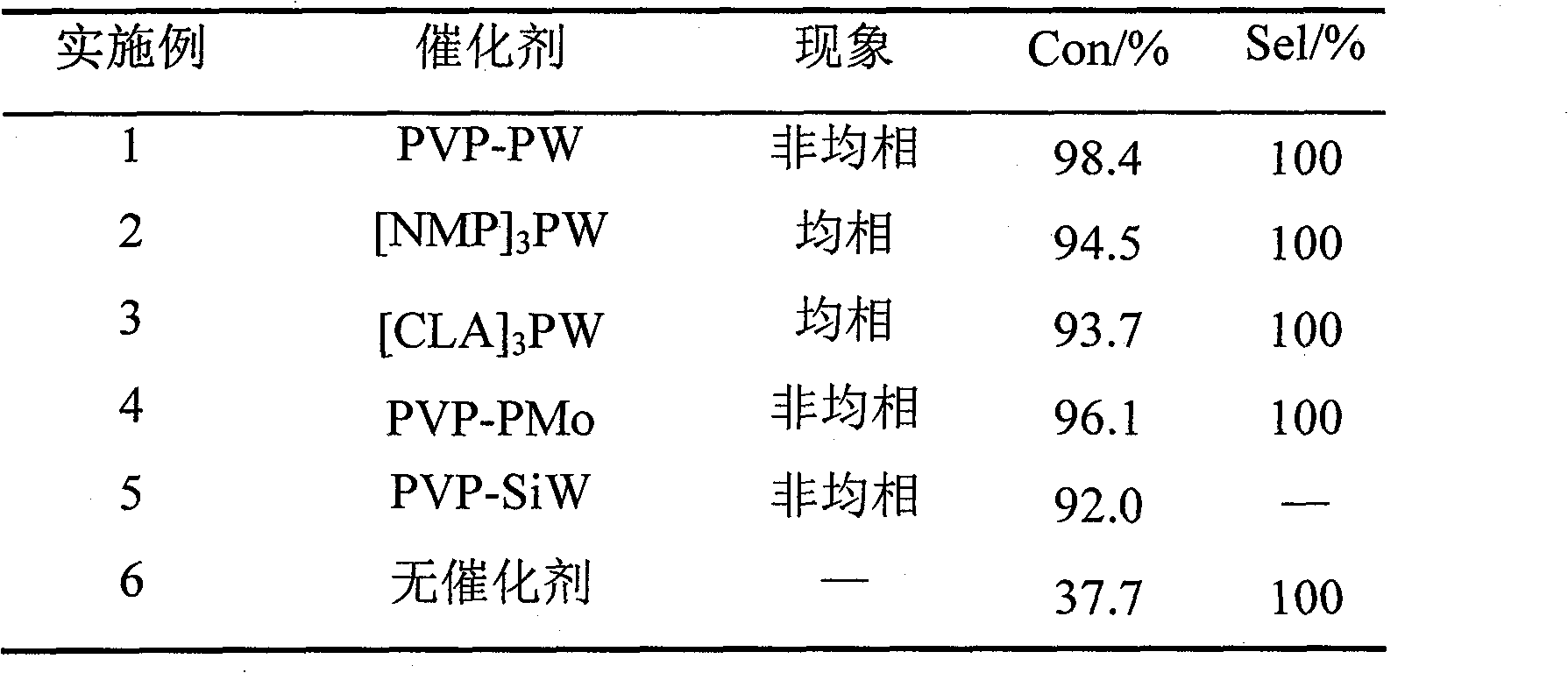

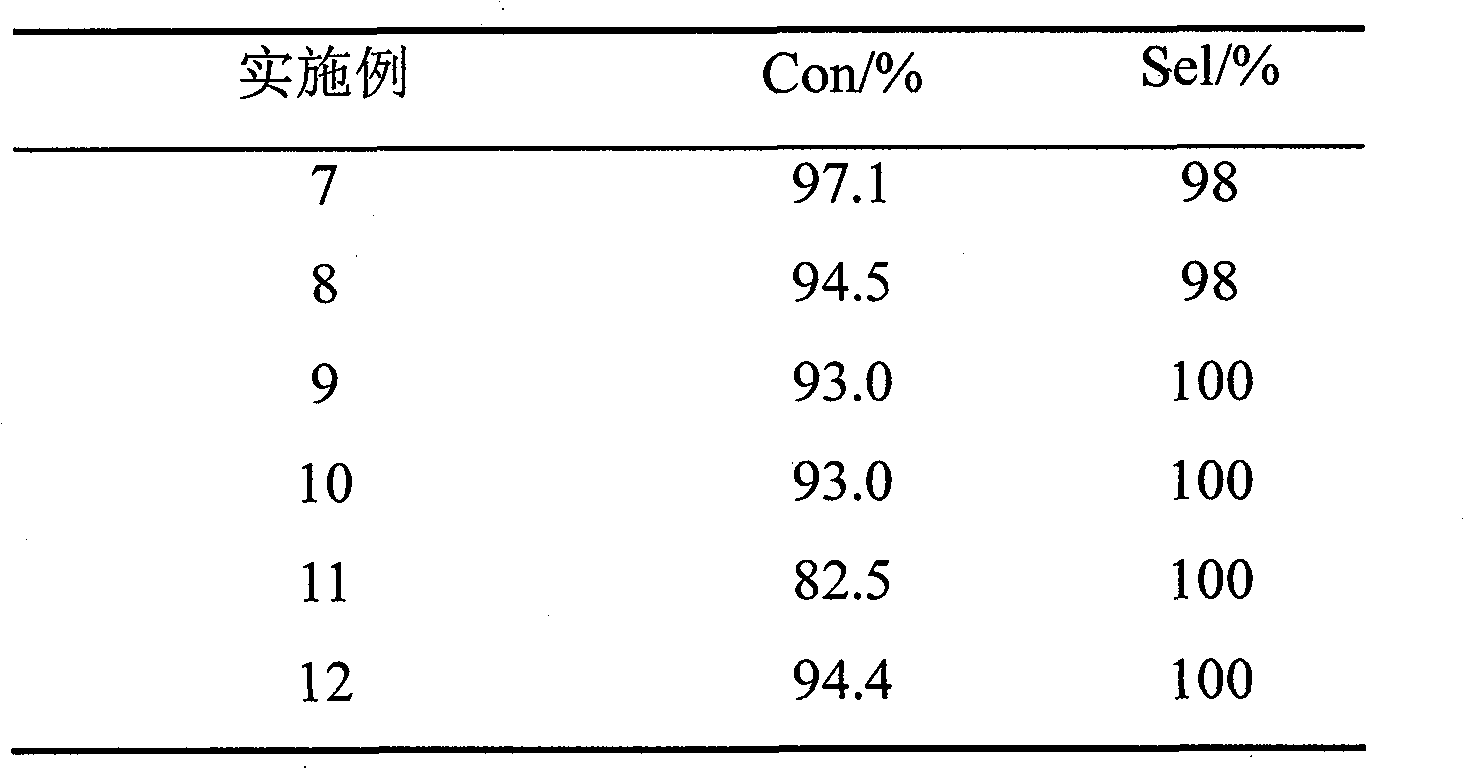

The invention discloses an organic heteropoly hybrid catalyst for an esterification reaction. The organic components comprise polyvinyl pyrrolidone, methyl-pyrrolidone and caprolactam. The heteropoly acid is 12-phosphotungstic acid, 12-phosphomolybdic acid and 12-silicotungstic acid. The preparation method comprises the step that the organic components and the heteropoly acids are subjected to protonation to obtain the organic heteropoly hybrid catalyst. The invention has the advantages that the preparation process of the catalyst is simple and practicable; and the obtained catalyst is suitable for the esterification reaction of many kinds of carboxylic acids and alcohol, and has the characteristics of high catalytic activity and selectivity, convenient recycling, and stable reutilization performance, thereby being an environment-friendly novel solid acid catalyst.

Owner:JIANGNAN UNIV

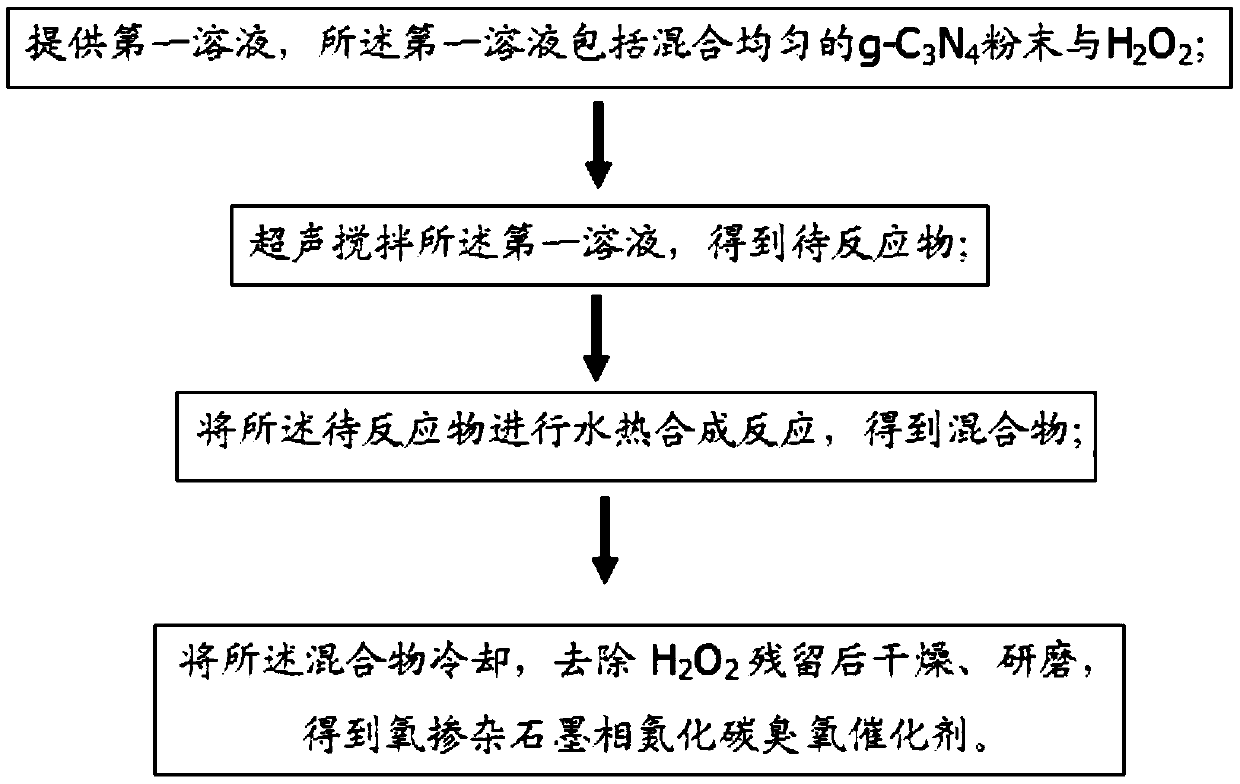

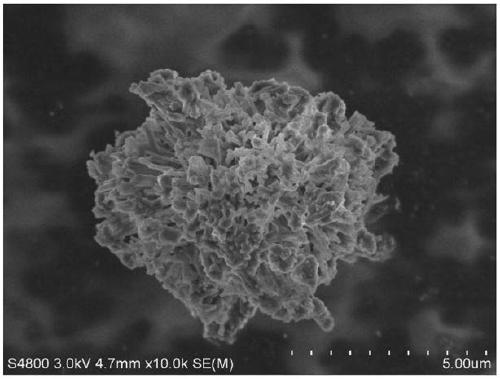

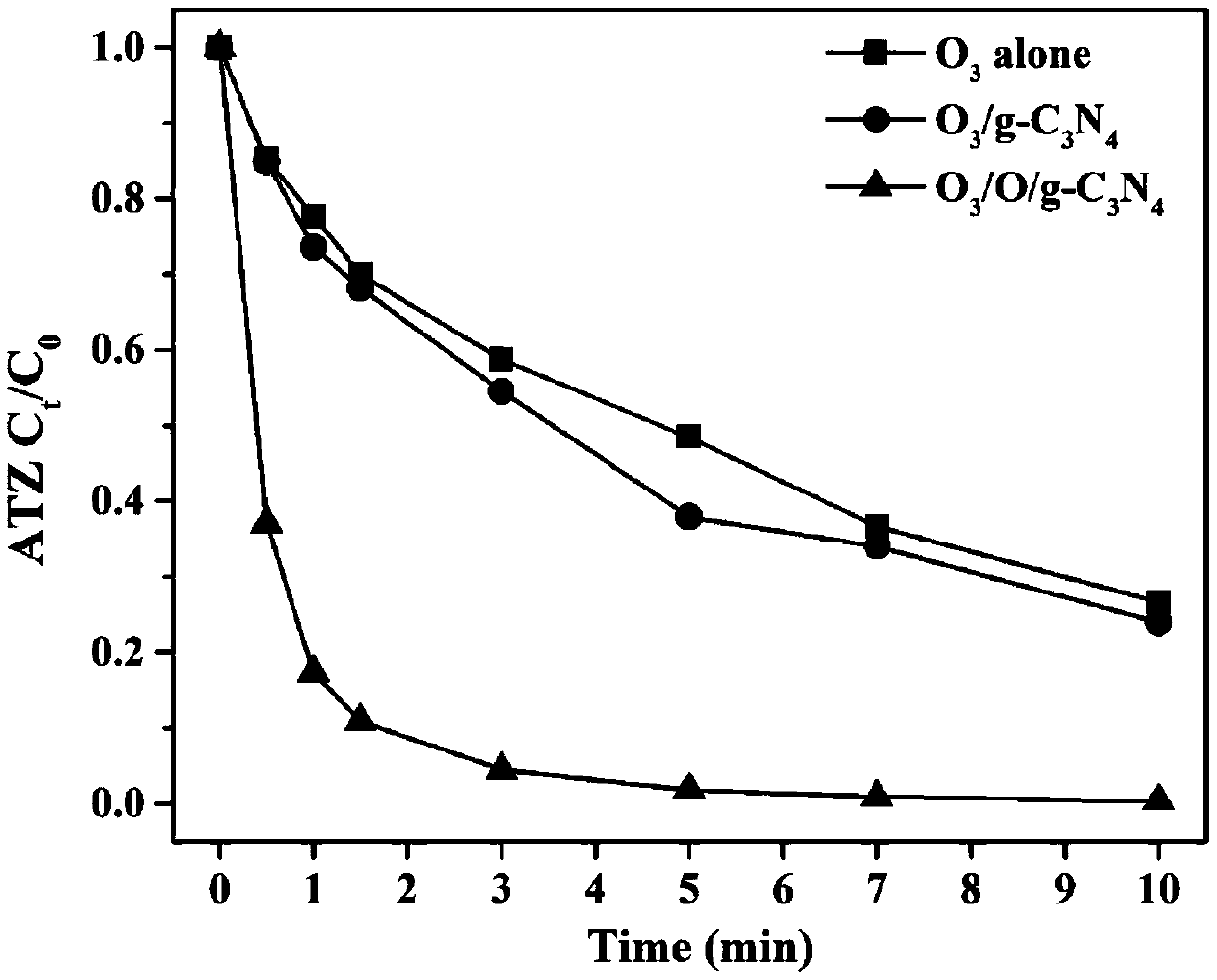

Preparation method and application of oxygen-doped graphite-phase carbon nitride ozone catalyst

ActiveCN106694021AImprove efficiencyAccelerated removal and degradationPhysical/chemical process catalystsWater treatment compoundsIonChemistry

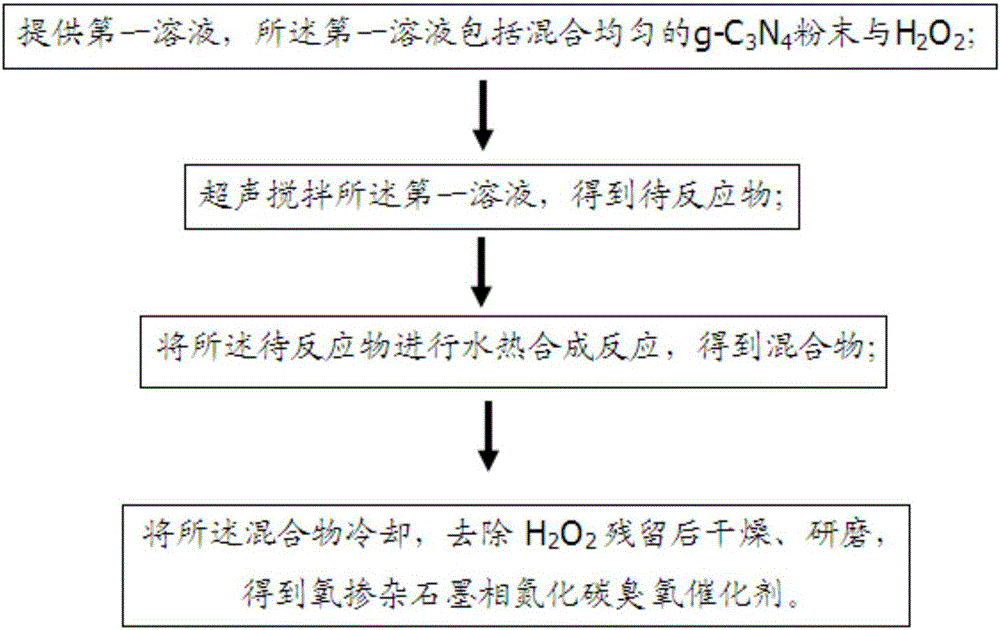

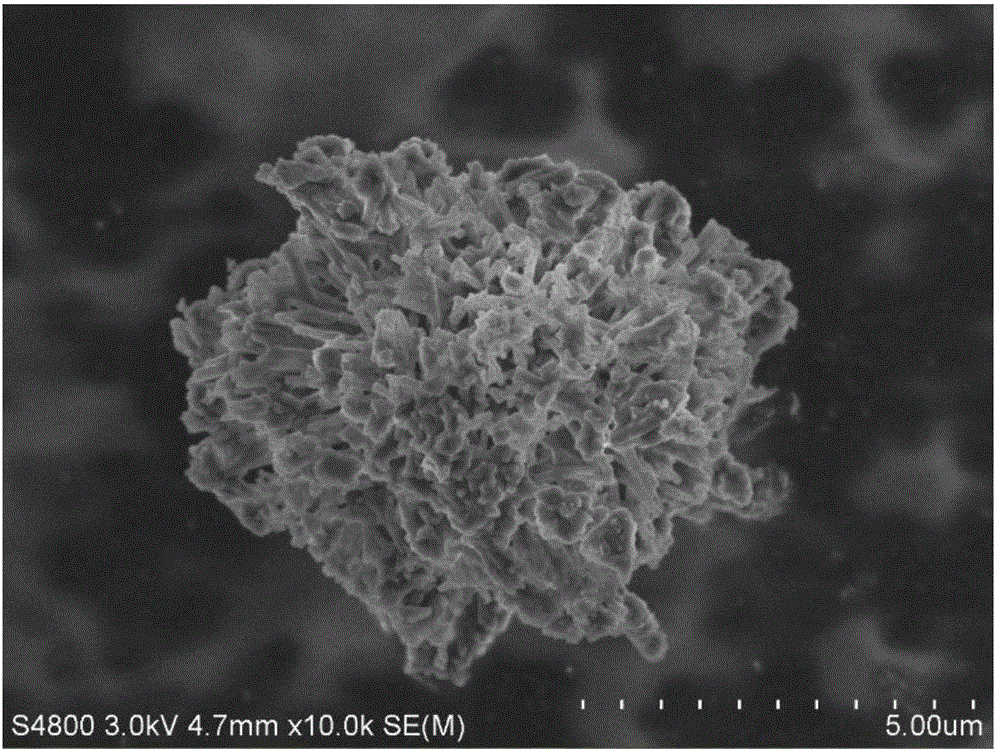

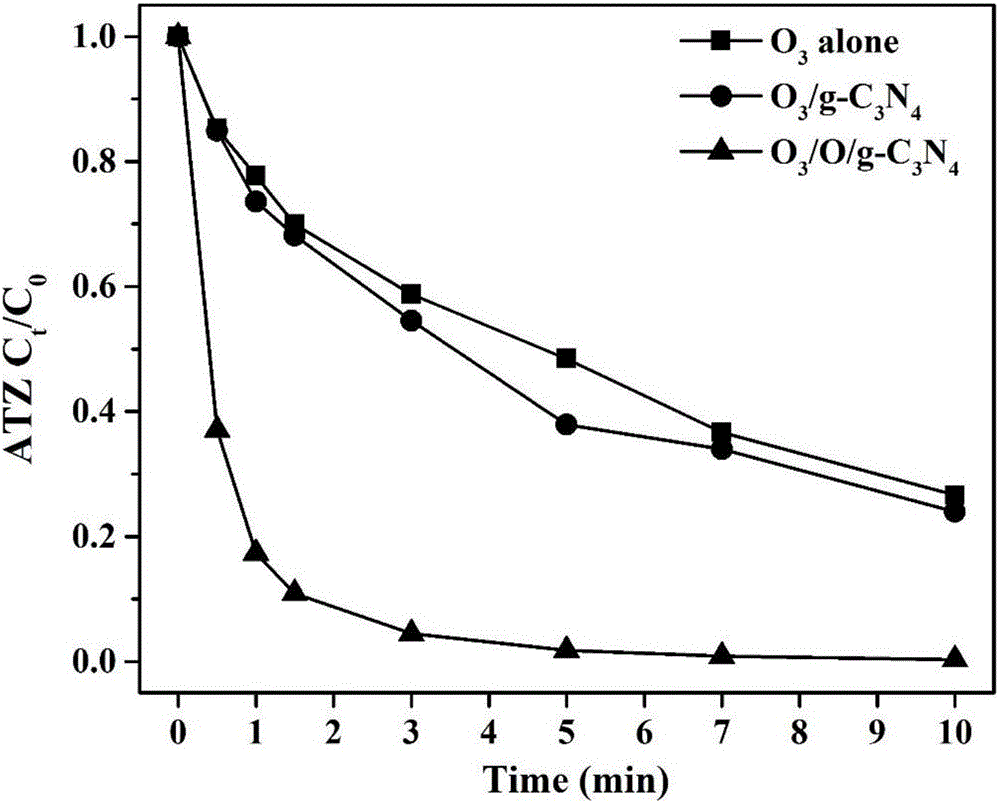

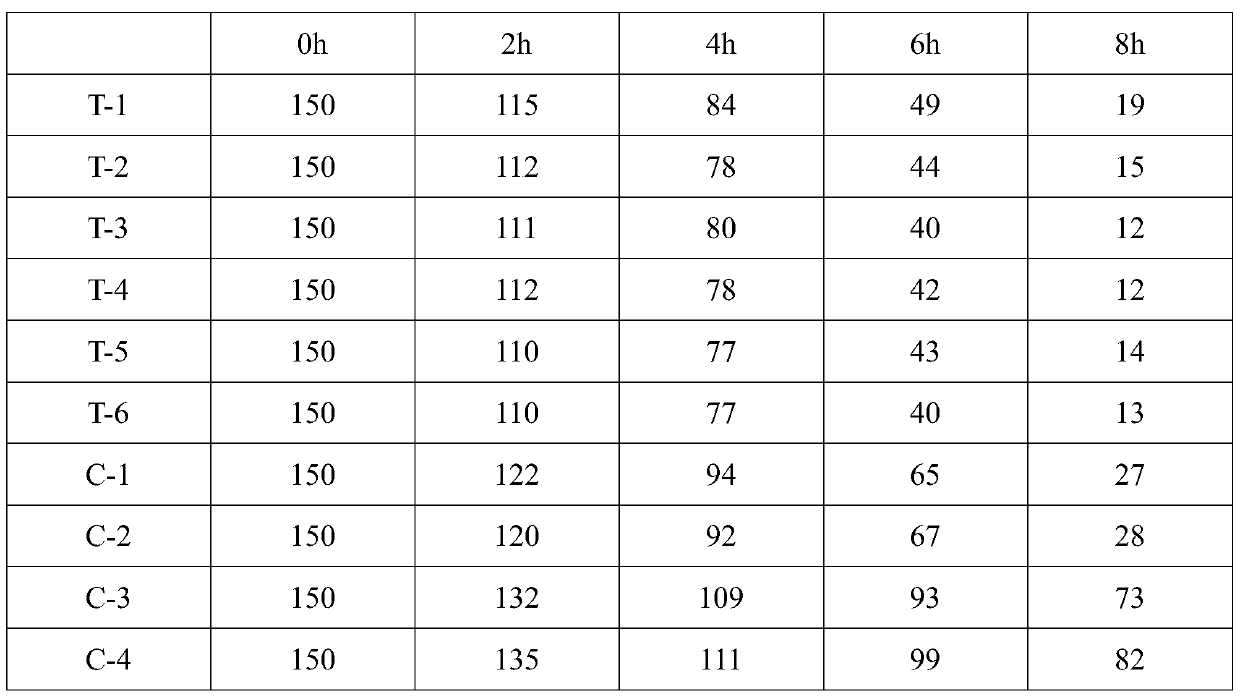

The invention provides a preparation method and application of an oxygen-doped graphite-phase carbon nitride ozone catalyst. The preparation method comprises the following steps that a first solution is prepared, wherein the first solution contains g-C3N4 powder and H2O2 which are mixed evenly and is ultrasonically stirred to obtain a substance about to react; hydrothermal synthesis reaction is conducted on the substance about to react to obtain a mixture; the mixture is cooled, H2O2 residues are removed, and then drying and grinding are performed to obtain the oxygen-doped graphite-phase carbon nitride ozone catalyst. Inorganic carbon and nitrogen materials are used for ozone catalysis process, and the problem that after reaction of traditional metal catalysts, part of metal ions is dissolved and accordingly catalyst activity reduction, further environmental pollution and the like are caused is solved.

Owner:WUHAN TEXTILE UNIV

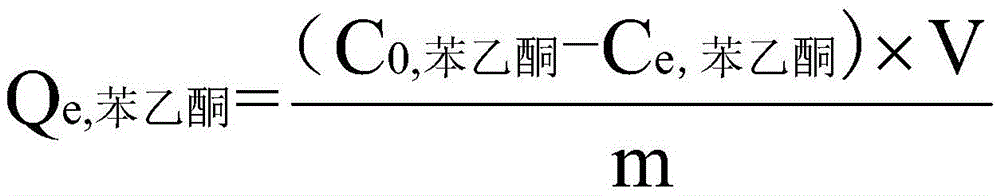

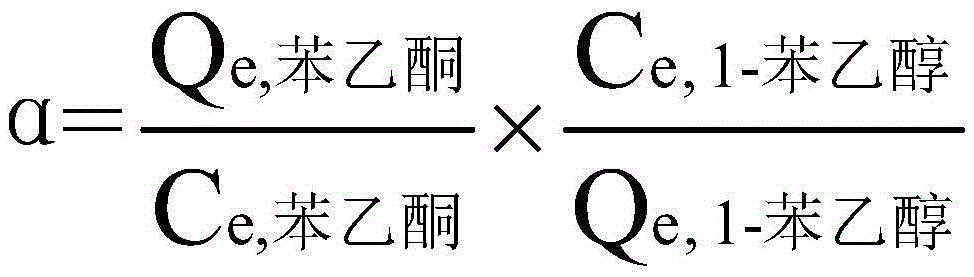

Method for selectively adsorbing and separating acetophenone and alpha-methyl benzyl alcohol

InactiveCN103288617AStable performance for repeated useSimple and gentle separation processHydroxy compound separation/purificationCarbonyl compound separation/purificationBENZYL ALCOHOL/WATERAcetophenone

The method discloses a method for selectively adsorbing and separating acetophenone and alpha-methyl benzyl alcohol. Based on the characteristics of the difference of the adsorption capacity of beta-cyclodextrin to the acetophenone and the alpha-methyl benzyl alcohol, the insolubility of the beta-cyclodextrin in a mixing solution of the acetophenone and the alpha-methyl benzyl alcohol and the like, the purpose of separation and purification is realized by performing preferential adsorption on the acetophenone under an moderate condition by taking the beta-cyclodextrin as an adsorbent. The method is moderate in separation condition, good in separation effect, simple in process, energy-saving, environmental-friendly and the like; and the adsorbent can be used repeatedly.

Owner:SUN YAT SEN UNIV

Modified silicone rubber composition, textile fabric and application thereof

ActiveCN111548632AIncreased degradation rateImprove stabilityWater contaminantsTreatment with anaerobic digestion processesAnthraquinonesPolymer science

The invention belongs to the technical field of wastewater treatment, and relates to a modified silicone rubber composition, a textile fabric and application thereof. The modified silicone rubber composition comprises silicone rubber and an anthraquinone-containing fluorosilicone compound, the weight ratio of the silicone rubber to the anthraquinone-containing fluorosilicone compound is 100: 0.05-3, and the anthraquinone-containing fluorosilicone compound is obtained by a reaction between an anthraquinone compound and a fluorosilicone polymer. The textile fabric prepared from the modified silicone rubber composition has a good effect of promoting the microbial degradation of azo dyes and nitrates.

Owner:福建拓烯新材料科技有限公司

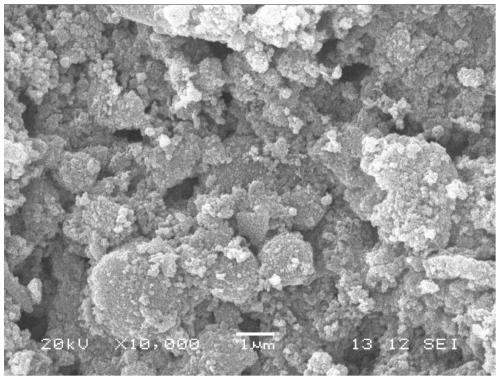

Preparation and application of ferroferric oxide composite metal chelate mimic enzyme

ActiveCN109499616AGood dispersionGood lookingMaterial analysis by observing effect on chemical indicatorOrganic-compounds/hydrides/coordination-complexes catalystsDispersityPeroxidase

The invention relates to a preparation and an application of a ferroferric oxide composite metal chelate mimic enzyme. According to the invention, a hydrothermal method is adopted for compounding Fe3O4-SL, wherein a big RCOO- group is derived from SL molecule and is attached to the surface of Fe3O4 powder; metal ions are absorbed by the Fe3O4-SL under a mild condition so as to form a nanometer composite material; due to static electricity and spatial effect, particles have excellent dispersity; the prepared Fe3O4 composite metal chelate has excellent microstructure and small grain size and hasexcellent peroxidase catalysis capacity; the separation process is simple, convenient and stable and the Fe3O4 composite metal chelate is reusable; a method for conveniently detecting hydrogen peroxide with high sensitivity and low cost is established on the basis of excellent peroxidase activity of Fe3O4 composite metal chelate mimic enzyme; the method has the advantages of mild reaction conditions, high detection speed, high sensitivity, high selectivity, capability of realizing visual rapid recognition and detection for hydrogen peroxide, and higher use value.

Owner:HANGZHOU DIANZI UNIV

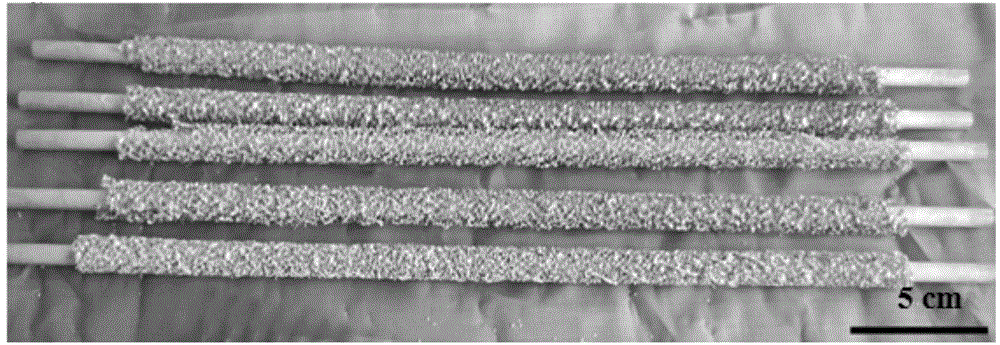

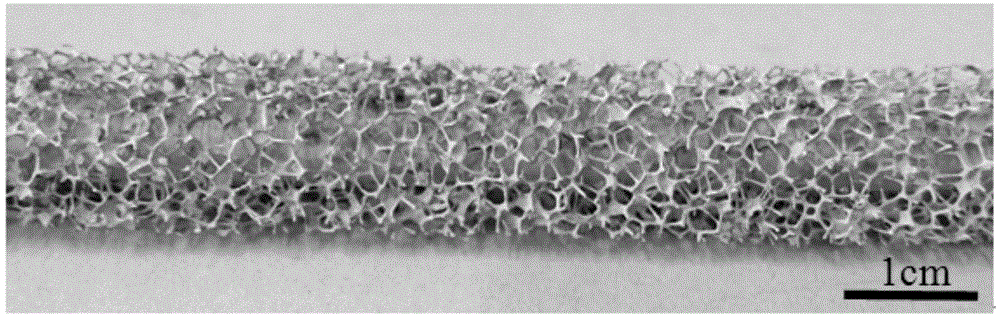

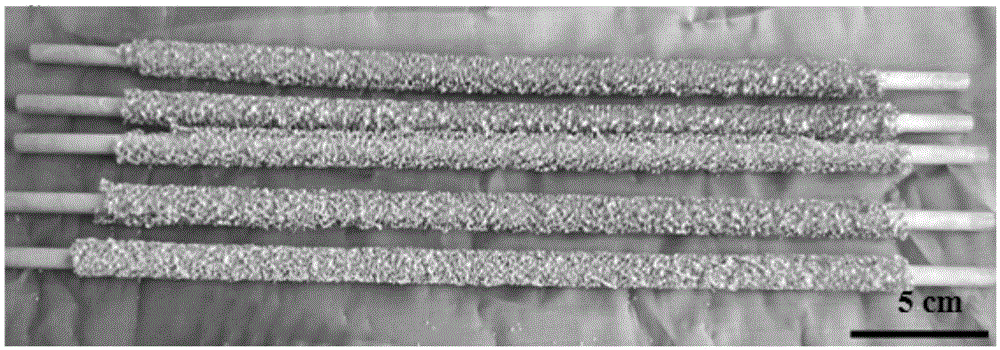

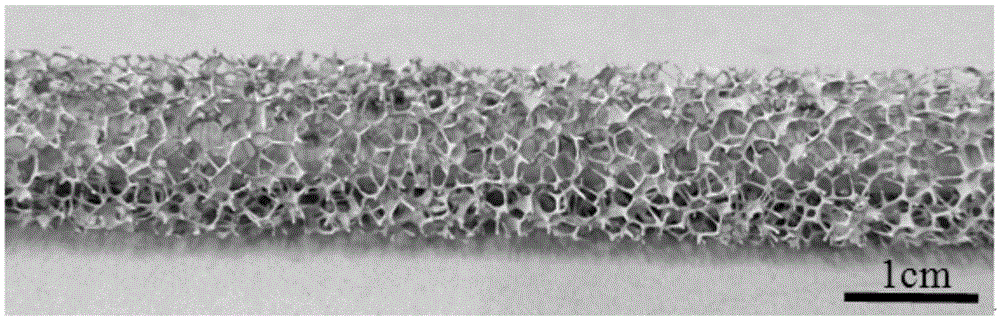

Method for manufacturing foam stainless steel composite tube

The invention discloses a method for manufacturing a foam stainless steel composite tube. The method includes the first step of preparing a dispersant, the second step of preparing stainless steel powder slurry, the third step of evenly coating the stainless steel powder slurry on the outer surface of a stainless steel tube, carrying out heat treatment after drying and obtaining a stainless steel powder sintered porous layer, the fourth step of covering the surface of the stainless steel powder sintered porous layer with a foam formwork, evenly applying the stainless steel powder slurry to the foam formwork, carrying out heat treatment after drying and obtaining a stainless steel foam layer, namely obtaining the foam stainless steel composite tube. According to the method, raw materials are wide in source range and easy to obtain, the manufacturing process is simple, the heat conductivity coefficient of the obtained foam stainless steel composite tube is reduced by more than 10 times compared with that of a stainless steel bare tube, critical heat flux density is improved more than twice, the specific area is large, and the foam stainless steel composite tube has the advantages of being good in machining performance, little in raw material consumption, large in heat exchange specific area and stable in repetitive use performance and can serve as a key part of a radiator.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

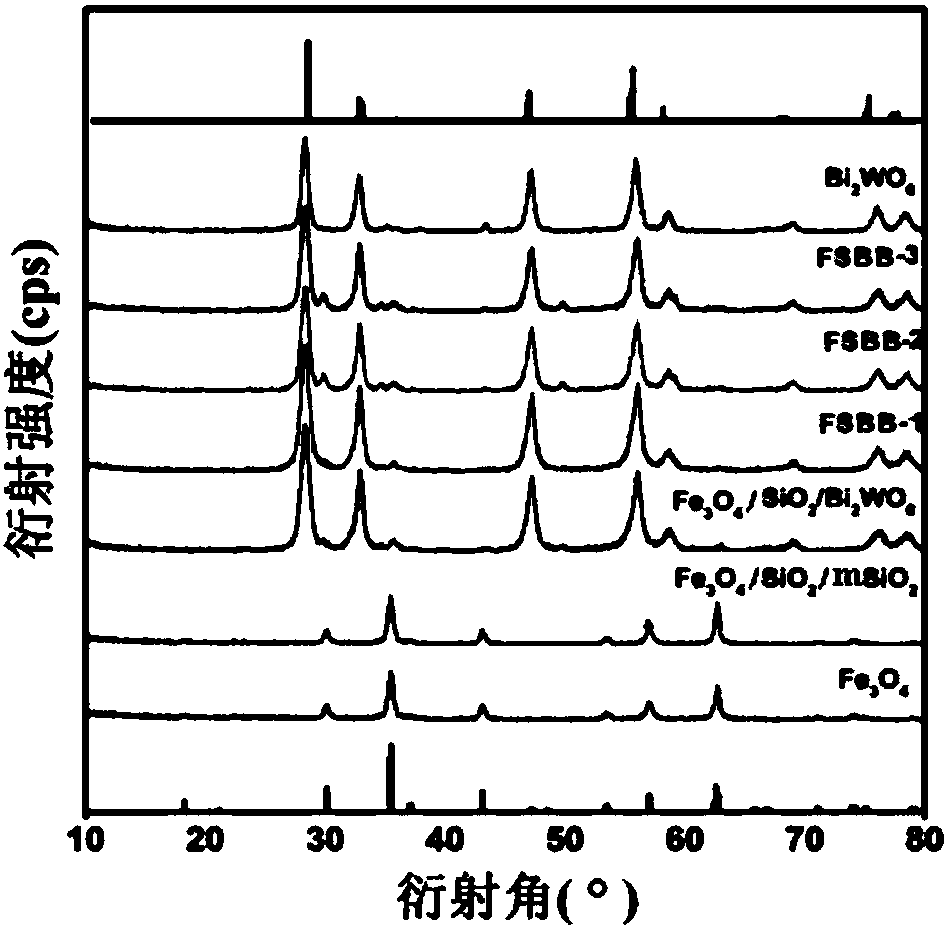

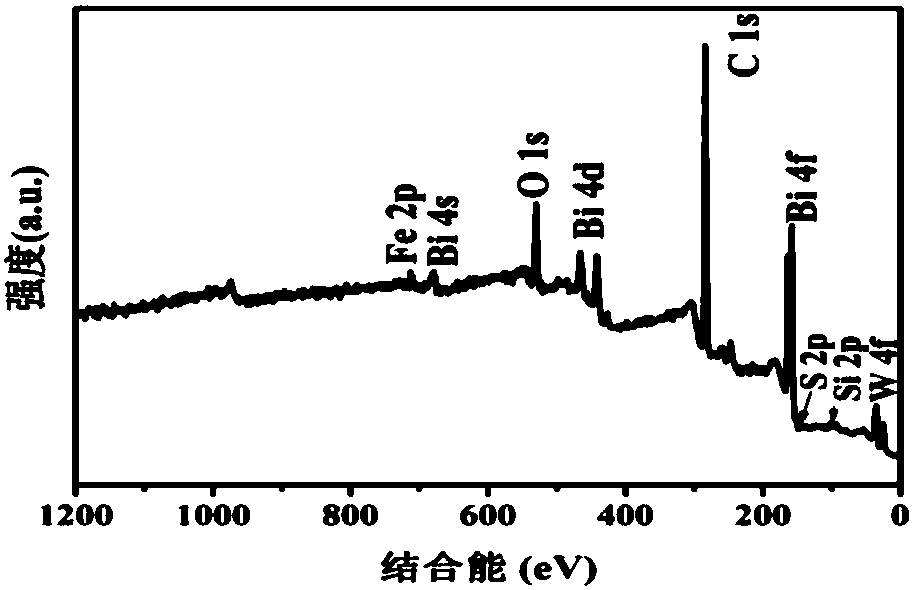

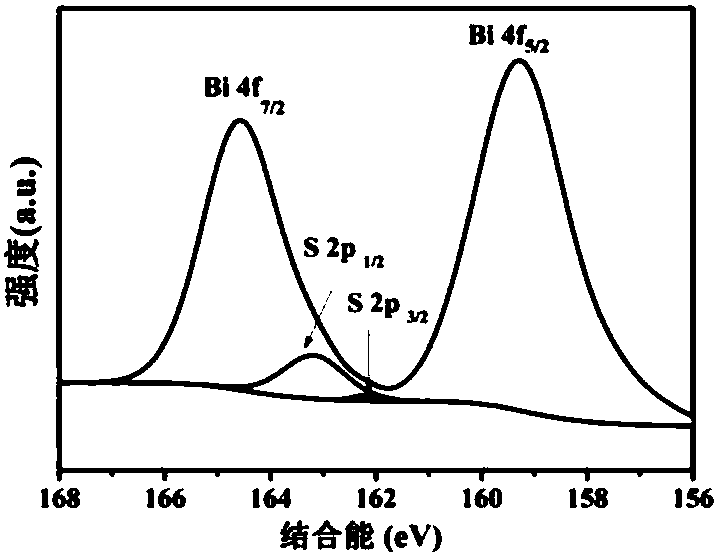

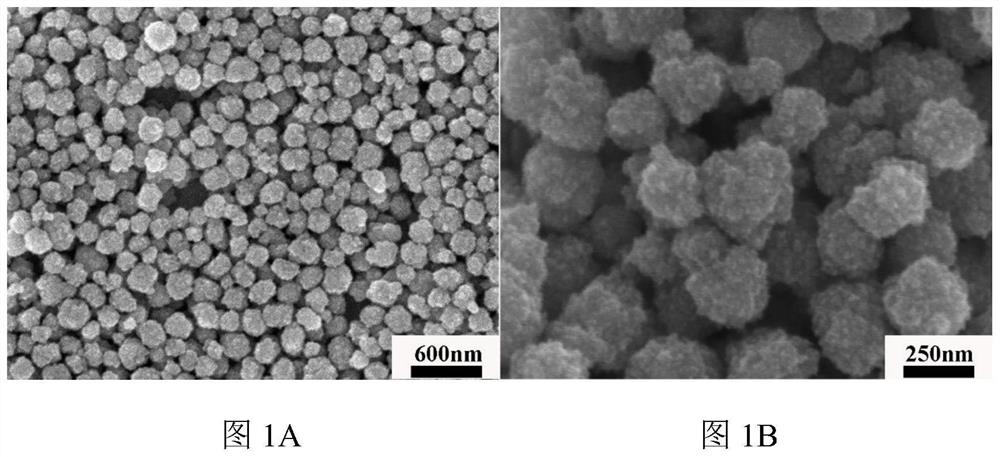

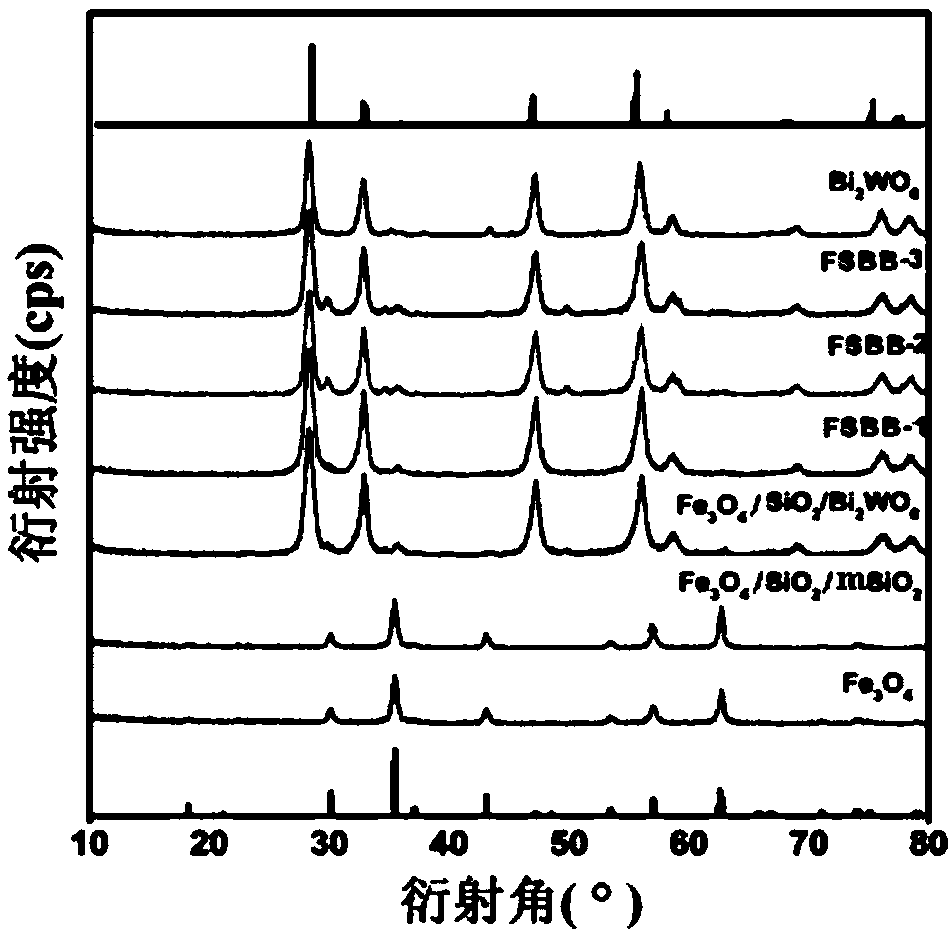

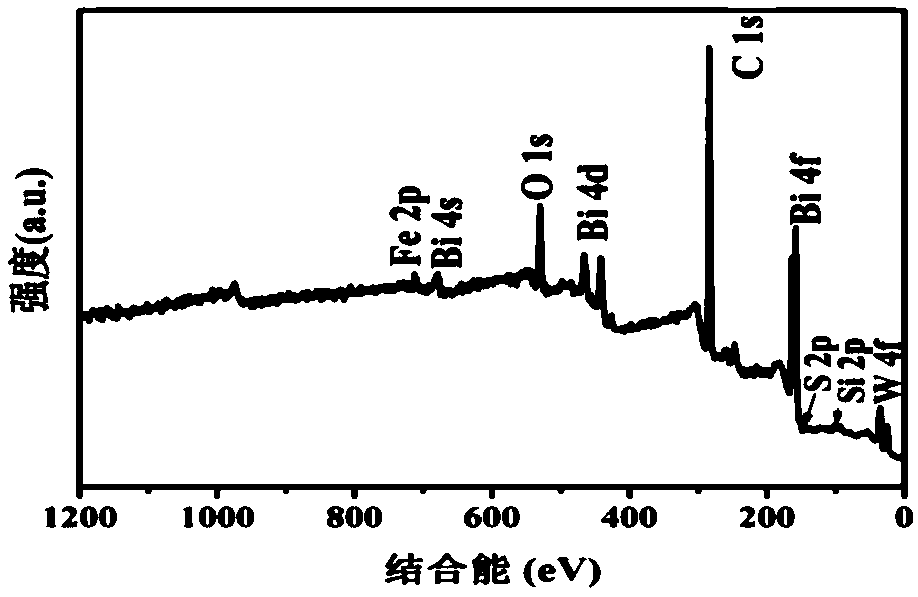

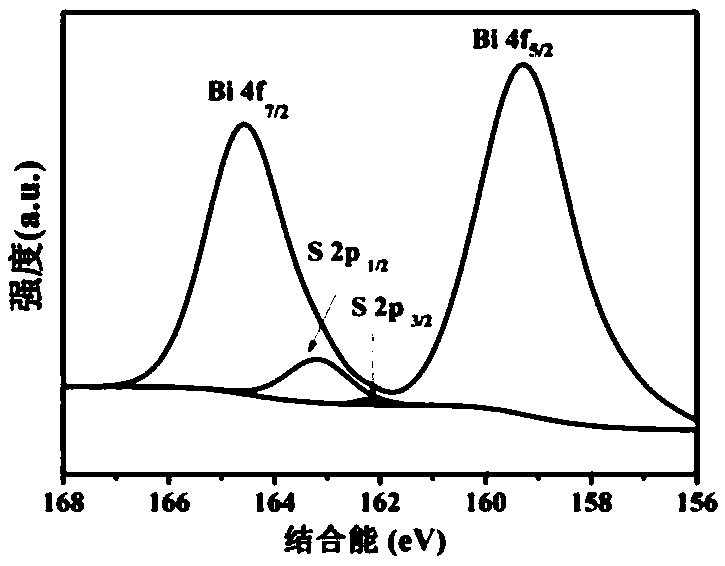

Magnetic compound photocatalytic material and preparation method thereof

ActiveCN108514884AHigh catalytic activityImprove controllabilityPhysical/chemical process catalystsWater/sewage treatment by irradiationSpectral responseReusability

The invention discloses a magnetic compound photocatalytic material which is prepared from Fe3O4 / SiO2 / mSiO2 with a 'core-shell' structure formed by wrapping Fe3O4 by two layers of SiO2, Bi2WO6 and Bi2S3. The invention also discloses a preparation method of the magnetic compound photocatalytic material. The compound photocatalytic material prepared through the method not only has a wide spectral response range and high visible-light catalytic activity, but also is easy to recover and stable in reusability.

Owner:YANAN UNIV

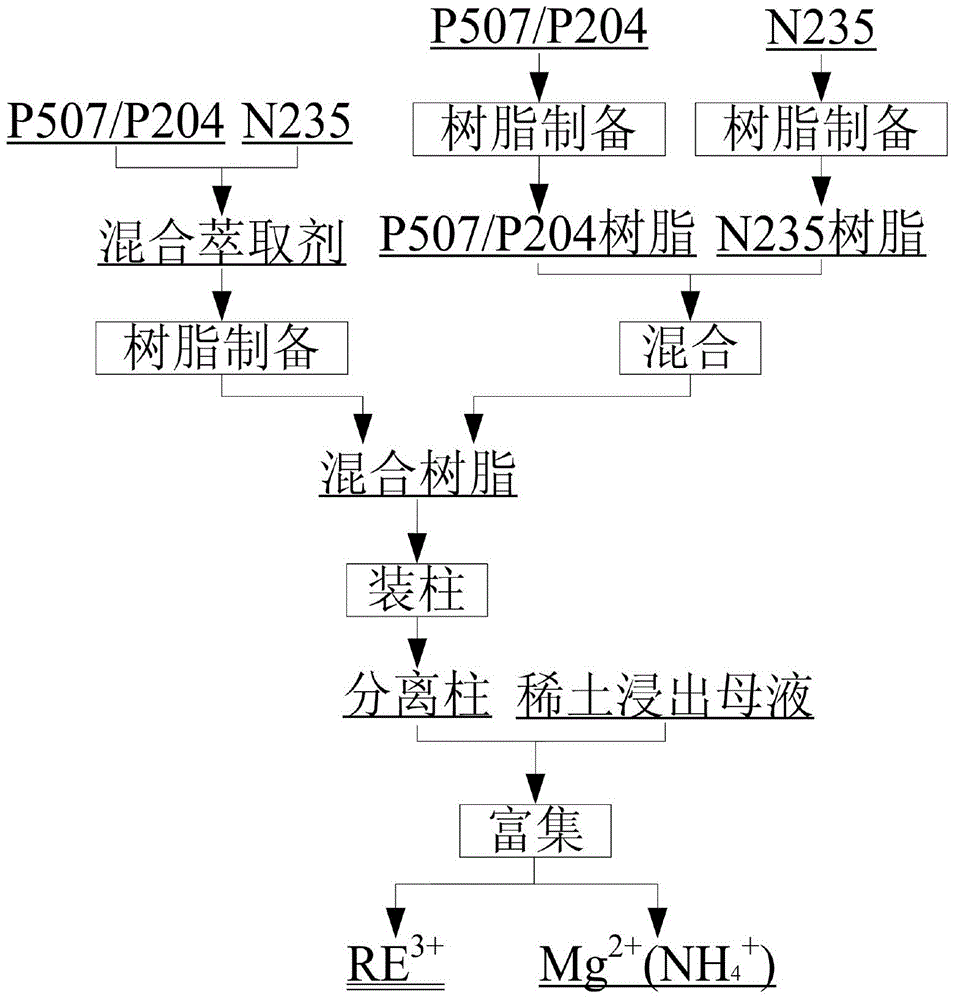

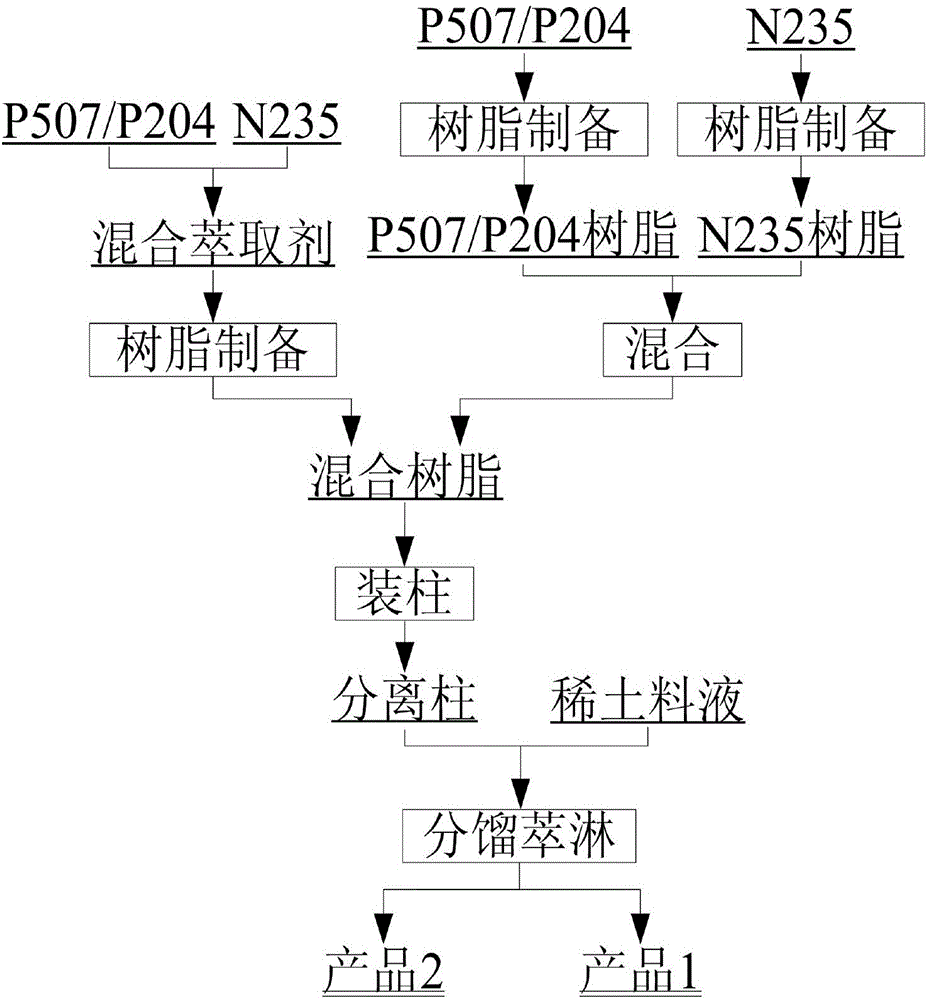

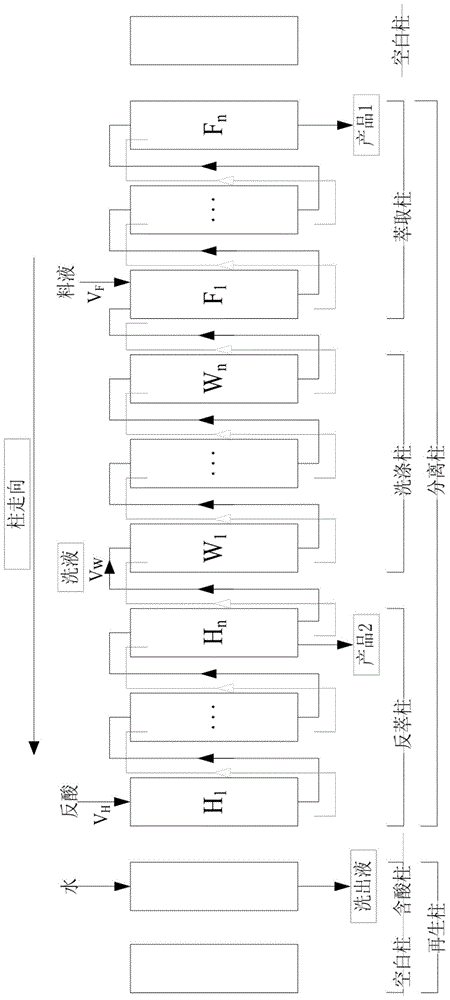

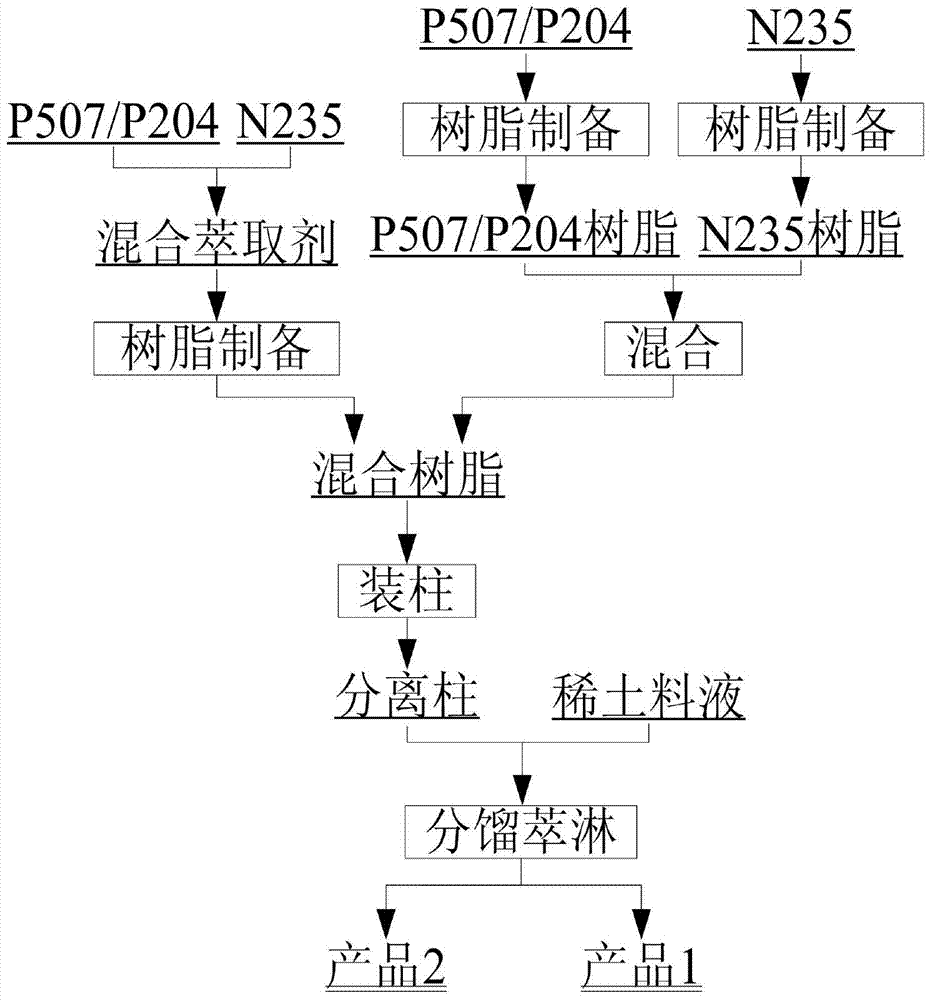

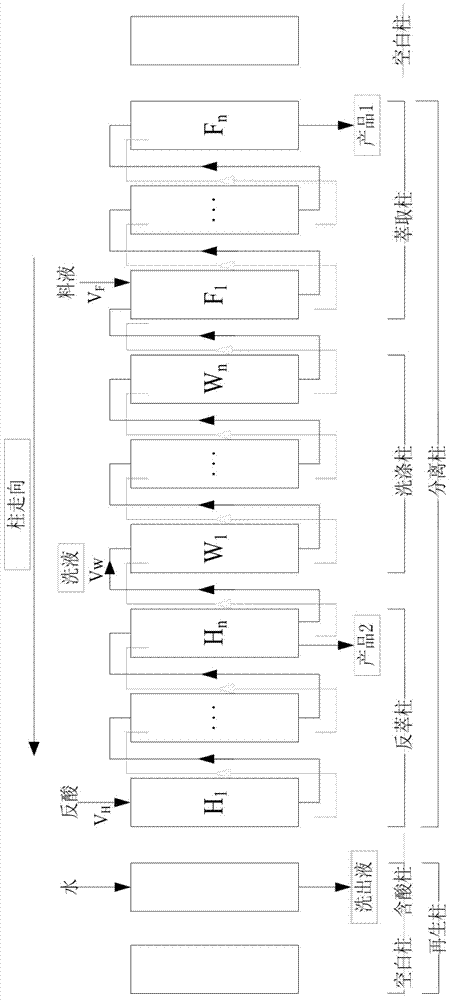

Method for enriching rare earth from rare earth leaching mother liquor

InactiveCN104593592ASolve pollutionSolve the problem of low rare earth adsorptionProcess efficiency improvementRare earth ionsIon exchange

The invention discloses a method for enriching rare earth from rare earth leaching mother liquor. The method comprises the following steps: (1) preparation of mixed resin, (2) column packing, (3) column enrichment, (4) column washing and (5) column cycling. The method has the positive effects that the rare earth leaching mother liquor is enriched by adopting an ion-exchange resin method, thus solving the problem of environmental pollution caused by precipitation; the problem of low rare earth adsorption quantity caused by low extraction equilibrium acidity of rare earth ions is solved by applying the H<+1> adsorption capacity of N235 resin; the problem of phase separation difficulty caused by traditional solvent extraction is solved by enriching the rare earth leaching mother liquor by an ion exchange method; a new method is provided for enrichment of the rare earth leaching mother liquor.

Owner:JIANGXI UNIV OF SCI & TECH +1

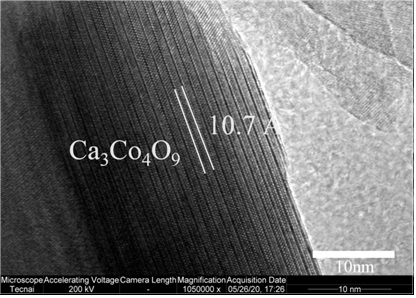

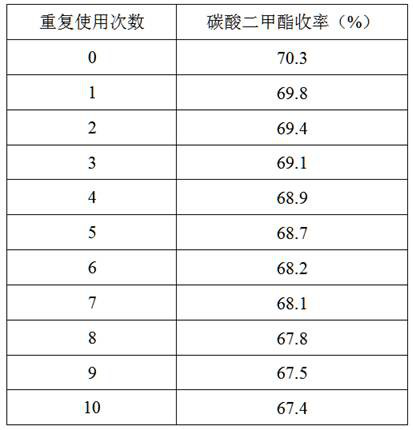

Application of Ca-based solid alkali heterogeneous catalyst in preparation of dimethyl carbonate

ActiveCN112624924AEasy to prepareStable and reusableOrganic compound preparationCatalyst activation/preparationTrans esterificationPtru catalyst

The invention provides an application of a Ca-based solid base heterogeneous catalyst in preparation of dimethyl carbonate. The Ca-based solid base heterogeneous catalyst is a Ca3Co4O9 catalyst and is used in a reaction for preparing dimethyl carbonate through transesterification of cyclic carbonate and methanol. The Ca-based solid alkali heterogeneous catalyst Ca3Co4O9 has the advantages of high temperature resistance, oxidation resistance, good thermal stability, high chemical stability and the like, loss of Ca active components can be effectively inhibited, high dimethyl carbonate yield is realized under normal-pressure and low-temperature reaction conditions, and in addition, the catalyst is simple in preparation method, stable in repeated use performance and suitable for industrial production. The industrial amplification is facilitated.

Owner:HENAN UNIVERSITY

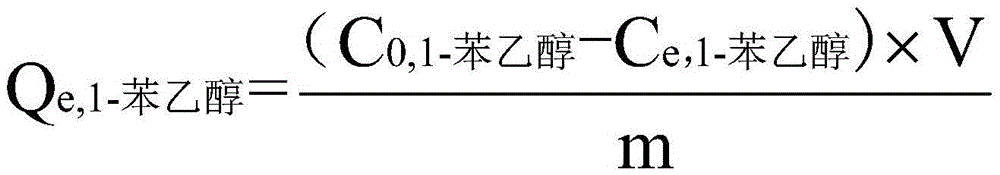

Acetophenone and 1-phenethyl alcohol separation method

InactiveCN105418380AHigh mechanical strengthImprove mechanical stabilityHydroxy compound separation/purificationCarbonyl compound separation/purificationPreferential adsorptionPhenethyl alcohol

The invention discloses an acetophenone and 1-phenethyl alcohol separation method. According to the method, the adsorption capacity difference of a soluble starch-immobilized beta-cyclodextrin polymer in adsorbing acetophenone and 1-phenethyl alcohol is used, the soluble starch-immobilized beta-cyclodextrin polymer is taken as an adsorbent, and an aim of separation purification is achieved by preferential adsorption to the acetophenone under a mild condition. The separation method has the advantages of being mild in separation condition, simple in process, simple and convenient in operation, good in separation effect, green and environment-friendly, good in adsorbent regenerability, low in running cost and the like.

Owner:GUANGXI UNIV

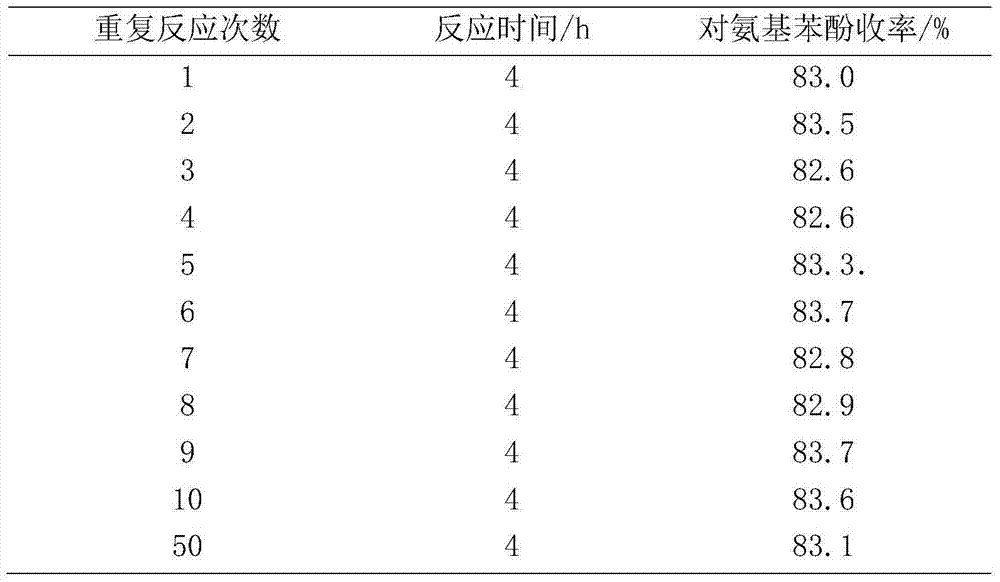

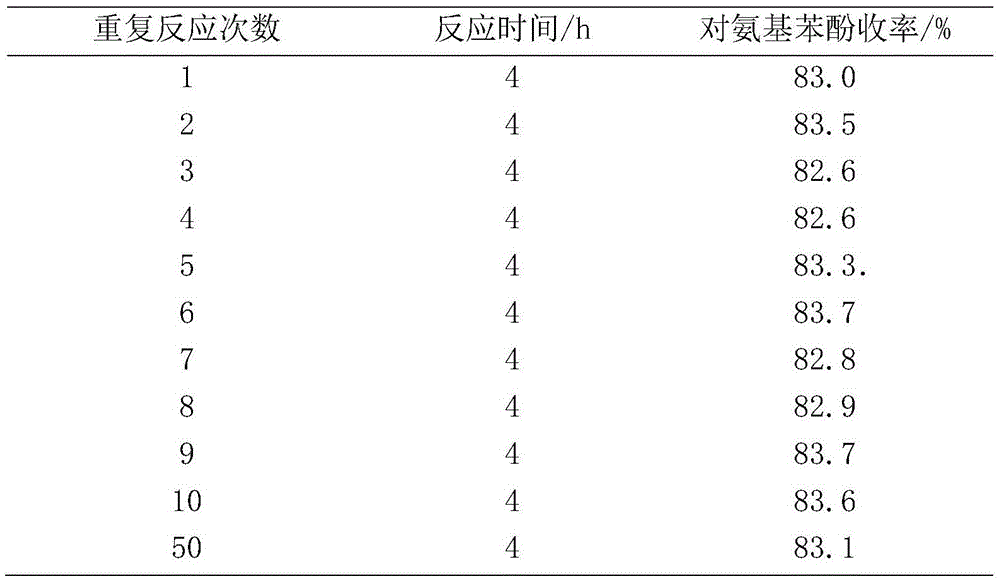

Process for synthesizing p-aminophenol through nitrobenzene hydrogenation

ActiveCN104326925ASimple equipment and processStable performance for repeated useOrganic compound preparationChemical recyclingNitrobenzeneChemistry

The present invention relates to a process for synthesizing p-aminophenol through nitrobenzene hydrogenation. The process comprises: adding water, concentrated sulfuric acid, zinc sulfate, nitrobenzene and a surfactant hexadecyl trimethyl ammonium bromide to a reactor provided with an active reaction member according to a mass ratio of concentrated sulfuric acid to zinc sulfate to nitrobenzene to hexadecyl trimethyl ammonium bromide to water of 0-20:0-2:2-20:0.01:100; and adopting N2 to replace air for 8-12 min, heating to a reaction temperature of 80-200 DEG C, introducing H2 to achieve a hydrogen partial pressure of 0.1-2.0 MPa, and carrying out a reaction for 3-8 h to make the nitrobenzene convert into the p-aminophenol. According to the present invention, the active reaction member is adopted to synthesize the p-aminophenol through nitrobenzene hydrogenation, wherein the highest p-aminophenol yield is 83.7%, the repeated use performance is stable, the reaction result does not significantly change after repeating the reaction more than 50 times, and the catalyst loss and regeneration problems are not produced during the reaction process.

Owner:HEBEI UNIV OF TECH

Method for separating squalene and vitamin E

ActiveCN106083518ASeparation process conditions are mildEasy to operateHydrocarbonsExtraction purification/separationVacuum dryingBeta-Cyclodextrins

The invention discloses a method for separating squalene and vitamin E. The method comprises the steps that beta-cyclodextrin is used for inclusion separation of a mixture containing squalene and natural vitamin E, and the purposes of purification and separation are achieved through preferential adsorption of squalene under the mild condition by using the difference of the weak interaction force of different substrates of beta-cyclodextrin, squalene and natural vitamin E. A small quantity of the squalene and natural vitamin E mixture dissolved with ethyl alcohol is dropwise added into a saturate beta-cyclodextrin aqueous solution at a constant temperature, stirring is carried out at the constant temperature, an inclusion complex is separated out after cooling and standing, filtering and vacuum drying are carried out, and squalene and natural vitamin E in the inclusion complex are extracted out with absolute ethyl alcohol. The method has the advantages of being mild in separating condition, simple in process, capable of saving energy, environmentally friendly, capable of recycling a separation carrier and avoiding the oxidation phenomenon which is likely to occur as the heat sensitivity of substances, and the like.

Owner:HUIZHOU RES INST OF SUN YAT SEN UNIV

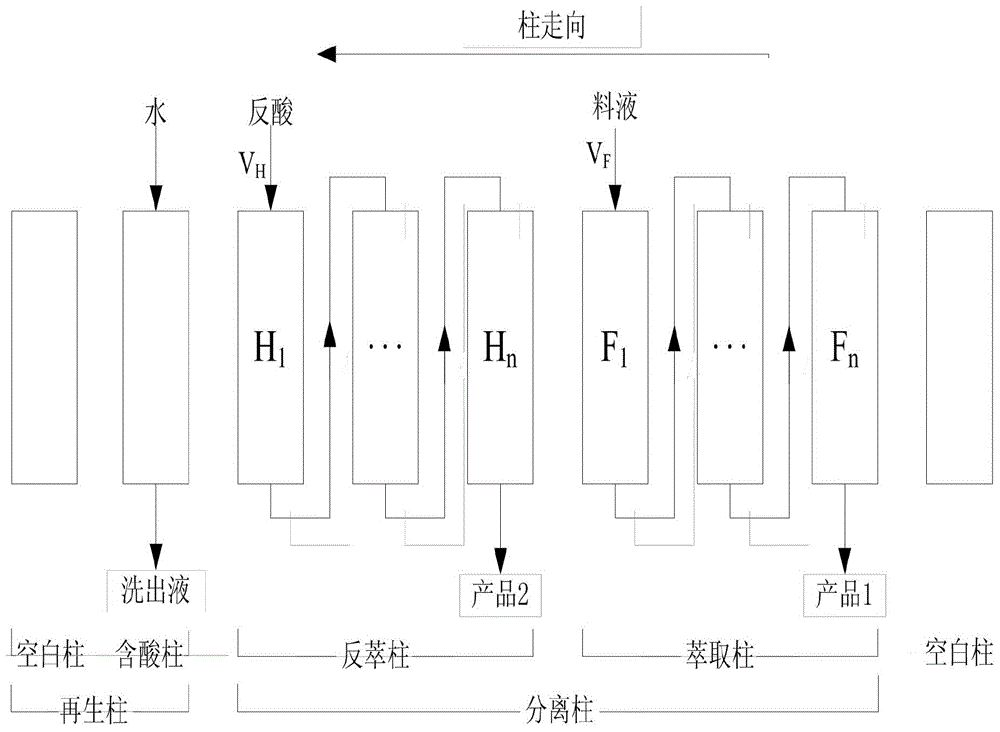

Method for separating rare earth elements

ActiveCN104593591ASolve pollutionSolve the problem of low rare earth adsorptionProcess efficiency improvementRare-earth elementAbsorption capacity

The invention discloses a method for separating rare earth elements. The method comprises the following steps: (1) preparation of mixed resin, (2) column packing, (3) column separation, (4) column washing and (5) column cycling. The method has the advantages that the rare earth elements are separated by adopting an ion-exchange resin method, thus solving the problem of environmental pollution caused by saponification; the problem of low rare earth adsorption quantity caused by low extraction equilibrium acidity of rare earth ions is solved by applying the H<+1> adsorption capacity of N235 resin; the exchange acidity of an adsorption zone can be controlled by utilizing the acid absorption capacity of N235, so that resin has better light rare earth separating capacity; separation of the rare earth elements by adopting a fractional extraction-elution process is achieved by utilizing a mode of connecting a plurality of columns in series and a new method is provided for separation of the rare earth elements.

Owner:宁夏同乐新材料科技有限责任公司

A method for separating rare earth elements

ActiveCN104593591BSolve pollutionSolve the problem of low rare earth adsorptionProcess efficiency improvementRare-earth elementAbsorption capacity

The invention discloses a method for separating rare earth elements. The method comprises the following steps: (1) preparation of mixed resin, (2) column packing, (3) column separation, (4) column washing and (5) column cycling. The method has the advantages that the rare earth elements are separated by adopting an ion-exchange resin method, thus solving the problem of environmental pollution caused by saponification; the problem of low rare earth adsorption quantity caused by low extraction equilibrium acidity of rare earth ions is solved by applying the H<+1> adsorption capacity of N235 resin; the exchange acidity of an adsorption zone can be controlled by utilizing the acid absorption capacity of N235, so that resin has better light rare earth separating capacity; separation of the rare earth elements by adopting a fractional extraction-elution process is achieved by utilizing a mode of connecting a plurality of columns in series and a new method is provided for separation of the rare earth elements.

Owner:宁夏同乐新材料科技有限责任公司

A kind of preparation method of foam stainless steel composite pipe

The invention discloses a method for manufacturing a foam stainless steel composite tube. The method includes the first step of preparing a dispersant, the second step of preparing stainless steel powder slurry, the third step of evenly coating the stainless steel powder slurry on the outer surface of a stainless steel tube, carrying out heat treatment after drying and obtaining a stainless steel powder sintered porous layer, the fourth step of covering the surface of the stainless steel powder sintered porous layer with a foam formwork, evenly applying the stainless steel powder slurry to the foam formwork, carrying out heat treatment after drying and obtaining a stainless steel foam layer, namely obtaining the foam stainless steel composite tube. According to the method, raw materials are wide in source range and easy to obtain, the manufacturing process is simple, the heat conductivity coefficient of the obtained foam stainless steel composite tube is reduced by more than 10 times compared with that of a stainless steel bare tube, critical heat flux density is improved more than twice, the specific area is large, and the foam stainless steel composite tube has the advantages of being good in machining performance, little in raw material consumption, large in heat exchange specific area and stable in repetitive use performance and can serve as a key part of a radiator.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

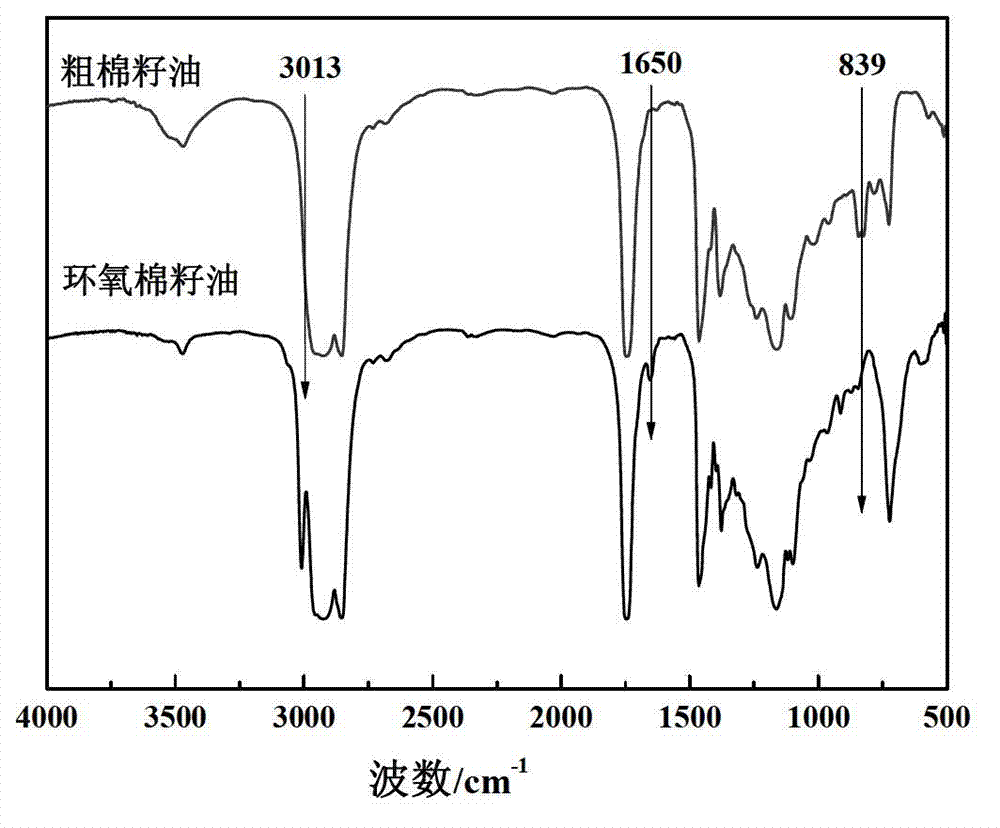

Preparation method and application of heterogeneous epoxy catalyst

InactiveCN103111329BSimple preparation processHigh catalytic activityOrganic chemistryFatty acid esterificationEpoxyPlasticizer

A preparation method and application of a heterogeneous epoxy catalyst belong to the technical field of catalyst preparation and application. With a high-molecular polymer as a carrier, the heterogeneous epoxy catalyst is grafted with a molybdenum metal complex after reacting with Schiff base ligand. The heterogeneous epoxy catalyst can be used for catalytic synthesis of epoxy aliphatic ester by using swill-cooked dirty oil as the initial raw material; and the epoxy aliphatic ester obtained is a novel environment-friendly plasticizer. The heterogeneous epoxy catalyst provided by the invention is simple in preparation process, and has the characteristics of high catalytic activity and selectivity, convenience in recovery, stable reusability and the like if applied to the epoxidation reactions. Besides, the waste edible oil is taken as the initial raw material for preparing the epoxy aliphatic ester so that the problems of recycling, environmental pollution and the like of the waste edible oil are solved; moreover, the epoxy aliphatic ester can be used for replacing the traditional orthophthalic plasticizers to a certain extent.

Owner:JIANGNAN UNIV +1

Nickel zinc ferrite/bismuth tungstate magnetic composite photocatalytic material and preparation method thereof

ActiveCN110102311BVisible light response range is wideVisible light catalytic activity is highWater/sewage treatment by irradiationWater treatment compoundsTungstateSeparation technology

The invention discloses a nickel-zinc ferrite / bismuth tungstate magnetic composite photocatalytic material, which is composed of Bi 2 WO 6 and Ni 0.5 Zn 0.5 Fe 2 O 4 Composed, where Ni 0.5 Zn 0.5 Fe 2 O 4 with Bi 2 WO 6 The mass ratio is 1‑4:10. The invention also discloses a method for preparing the nickel-zinc ferrite / bismuth tungstate magnetic composite photocatalytic material. The nickel-zinc ferrite / bismuth tungstate magnetic composite photocatalytic material has a wide visible light response range, high visible light catalytic activity, is easy to be recycled through magnetic separation technology, and has stable reuse performance.

Owner:YANAN UNIV

A kind of technique for synthesizing p-aminophenol by hydrogenation of nitrobenzene

ActiveCN104326925BNo lossNo internal diffusion effectOrganic compound preparationChemical recyclingSulfateReaction temperature

The present invention relates to a process for synthesizing p-aminophenol through nitrobenzene hydrogenation. The process comprises: adding water, concentrated sulfuric acid, zinc sulfate, nitrobenzene and a surfactant hexadecyl trimethyl ammonium bromide to a reactor provided with an active reaction member according to a mass ratio of concentrated sulfuric acid to zinc sulfate to nitrobenzene to hexadecyl trimethyl ammonium bromide to water of 0-20:0-2:2-20:0.01:100; and adopting N2 to replace air for 8-12 min, heating to a reaction temperature of 80-200 DEG C, introducing H2 to achieve a hydrogen partial pressure of 0.1-2.0 MPa, and carrying out a reaction for 3-8 h to make the nitrobenzene convert into the p-aminophenol. According to the present invention, the active reaction member is adopted to synthesize the p-aminophenol through nitrobenzene hydrogenation, wherein the highest p-aminophenol yield is 83.7%, the repeated use performance is stable, the reaction result does not significantly change after repeating the reaction more than 50 times, and the catalyst loss and regeneration problems are not produced during the reaction process.

Owner:HEBEI UNIV OF TECH

A kind of preparation method and application of oxygen-doped graphite phase carbon nitride ozone catalyst

ActiveCN106694021BPromote degradationGood removal effectPhysical/chemical process catalystsWater contaminantsMetal catalystCarbon nitride

The invention provides a preparation method and application of an oxygen-doped graphite phase carbon nitride ozone catalyst. The preparation method includes the following steps: providing a first solution, the first solution including uniformly mixed g-C 3 N 4 Powder and H 2 O 2 , ultrasonically stir the first solution to obtain the reactant; subject the reactant to a hydrothermal synthesis reaction to obtain a mixture; cool the mixture to remove H 2 O 2 The residue is dried and ground to obtain an oxygen-doped graphite phase carbon nitride ozone catalyst. The present invention uses inorganic carbon-nitrogen materials in the ozone catalytic process, which solves the problems of partial metal ions dissolving out after the reaction of traditional metal catalysts, resulting in reduced catalyst activity and further environmental pollution.

Owner:WUHAN TEXTILE UNIV

Preparation and application of a kind of ferric oxide complex metal chelate mimetic enzyme

ActiveCN109499616BGood dispersionGood lookingMaterial analysis by observing effect on chemical indicatorOrganic-compounds/hydrides/coordination-complexes catalystsNano compositesPeroxidase

The invention relates to the preparation and application of a complex metal chelate mimetic enzyme of ferric oxide. The present invention adopts hydrothermal method to synthesize Fe 3 o 4 ‑SL, SL molecules derive large RCOO‑groups, adsorbed on Fe 3 o 4 On the surface of the powder, the metal ions are covered by Fe under mild conditions 3 o 4 ‑SL is adsorbed to form nanocomposites, and the particles have good dispersion due to electrostatic and steric effects; and the prepared Fe 3 o 4 Composite metal chelates have good morphology and small particle size, have excellent peroxidase catalytic ability, and the separation process is simple, convenient, stable and reusable; based on Fe 3 o 4 The complex metal chelate mimics the excellent peroxidase activity of the enzyme, and a highly sensitive, low-cost, and simple method for the detection of hydrogen peroxide is established. The reaction condition is mild, the detection speed is fast, the sensitivity is high, and the selectivity is good, which can realize the visual and rapid identification and detection of hydrogen peroxide, and has high use value.

Owner:HANGZHOU DIANZI UNIV

A kind of magnetic composite photocatalytic material and preparation method thereof

ActiveCN108514884BHigh catalytic activityImprove controllabilityPhysical/chemical process catalystsWater/sewage treatment by irradiationSpectral responseReusability

The invention discloses a magnetic composite photocatalytic material, which consists of two layers of SiO 2 PackageFe 3 O 4 Fe forming a “core‑shell” structure 3 O 4 / SiO 2 / mSiO 2 , the composite photocatalytic material also includes Bi 2 WO 6 and Bi 2 S 3 ; The invention also discloses a method for preparing this magnetic composite photocatalytic material. The composite photocatalytic material prepared by this method not only has a wide spectral response range and high visible light catalytic activity, but is also easy to recycle, and its reusability is also very stable.

Owner:YANAN UNIV

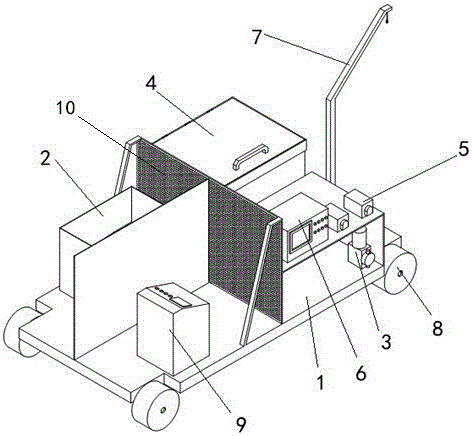

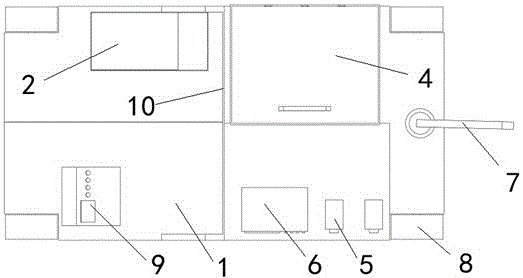

Emergency treatment apparatus applicable to catalytic oxidation of high-risk wastewater

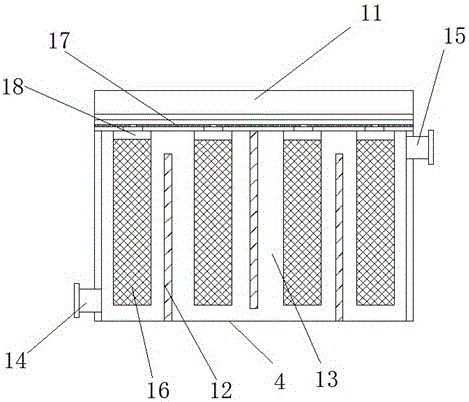

PendingCN106517483AStable catalytic oxidation reactionDoes not affect normal workWater/sewage treatment by irradiationWater treatment compoundsEmergency treatmentCatalytic oxidation

The invention discloses an emergency treatment apparatus applicable to catalytic oxidation of high-risk wastewater. The emergency treatment apparatus comprises a base plate, an oxidizing agent storage zone, a mixer, a catalytic converter, a pressure water pump and a three-way valve, wherein the oxidizing agent storage zone, the mixer, the catalytic converter and the pressure water pump are all fixedly mounted on the base plate; the wastewater inlet pipe of the apparatus is connected with the water inlet of the three-way valve via the pressure water pump; the other water inlet of the three-way valve is connected with the oxidizing agent storage zone; the water outlet of the three-way valve is connected with the mixer; the mixer is connected with the water inlet of the catalytic converter; and the catalytic converter is provided with a water outlet which is connected with a wastewater outlet pipe. The apparatus provided by the invention treats wastewater by using the principles of cooperation between photocatalysis and chemical catalysis and can realize diversified treatment of a plurality of components in sewage; process conditions of oxidation and degradation are mild; heating is not needed; the range of the acid-base value of sewage is wide; no secondary pollution is produced; and a catalyst is shaped and can be repeatedly and stably used.

Owner:SOUTHEAST UNIV +1

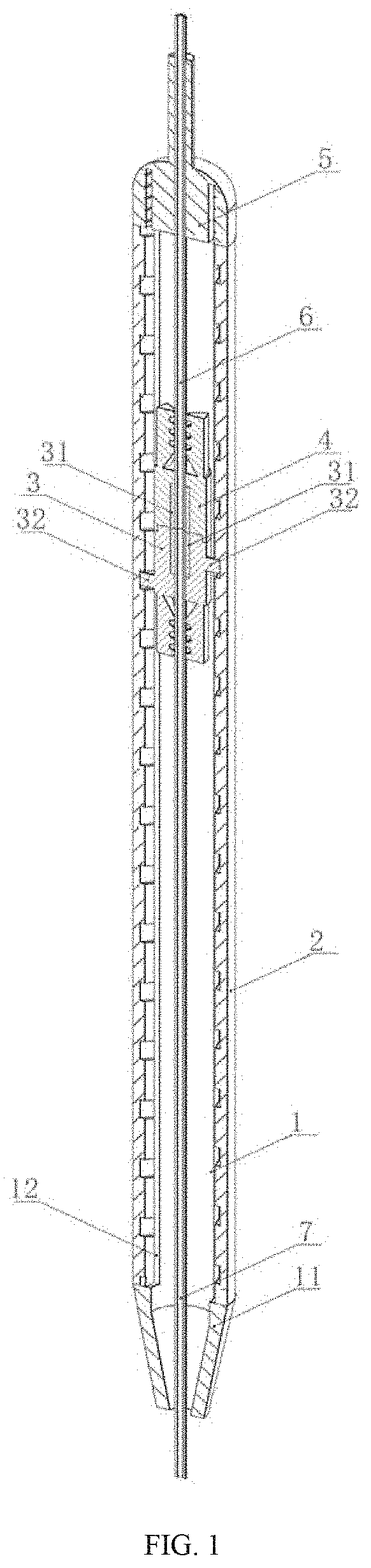

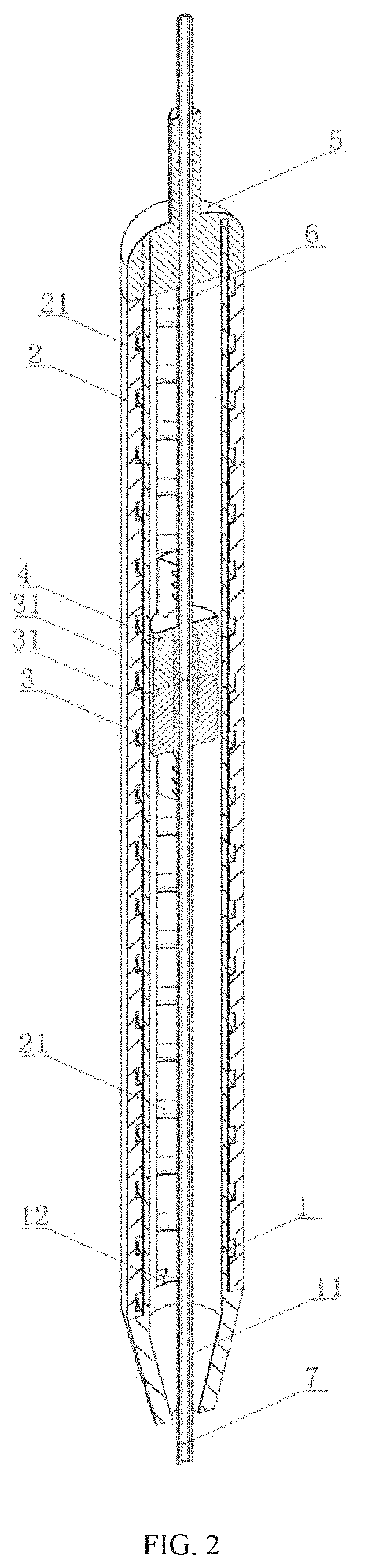

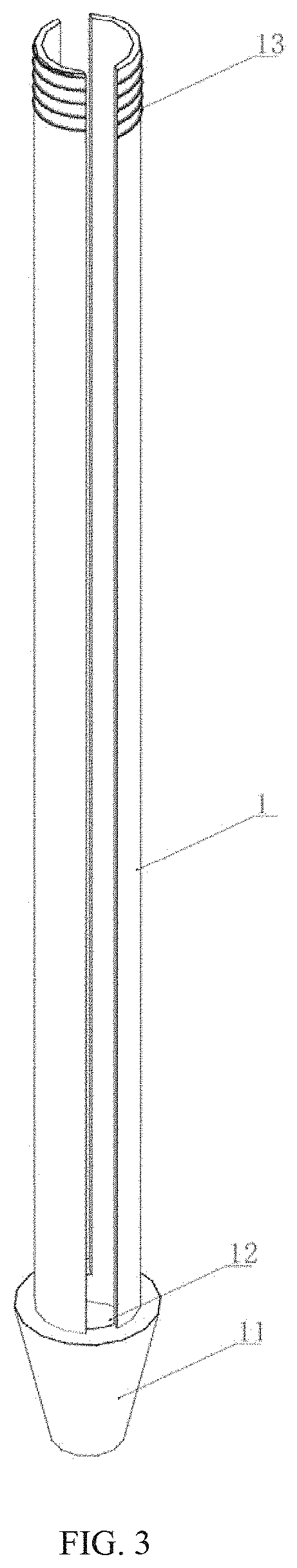

Pencil-like optical fiber sensor probe, portable immunosensor and use thereof

ActiveUS20210123908A1Long detection timeKeep for a long timeThermometer detailsBiological material analysisImmune profilingReagent strip

The present invention discloses a pencil-like optical fiber sensor probe, including an inner tube, a light screening casing, a clamping device, an optical fiber and an optical probe; a portable immunosensor, including the pencil-like optical fiber sensor probe, an immersion immune response reagent strip, a touch-screen computer, a compact battery-powered sensitive photon counting detector and a case; and a use of the immunosens in detecting inflammatory markers. The design of the pencil-like optical sensor probe greatly simplifies the immune analysis process by combining the immersion immune response reagent strip. Each optical probe allows for up to 10 immunoassays, which reduces the experimental cost and avoids frequent replacement of the probe. The integrated detecting system is powered by battery which is suitable for in-situ analysis and detection. The sensor also has a high stability and sensitivity.

Owner:NORTHEAST NORMAL UNIVERSITY +1

PCR validation tubes

InactiveUS20150159197A1Stable and reusableGood optical performanceMicrobiological testing/measurementFluorescence/phosphorescenceFluorophoreThermal cycler

This invention relates to a PCR fluorescence reference standard and to a method for manufacturing a PCR fluorescence reference standard. The PCR fluorescence reference standard comprises a fluorophore suspended in a thermoplastic polymer matrix. The PCR fluorescence reference standard of the invention has a greater shelf life than fluorophores dissolved in a solution and can advantageously be used to validate a fluorescence signal obtained in a thermal cycler.

Owner:STARNA SCI

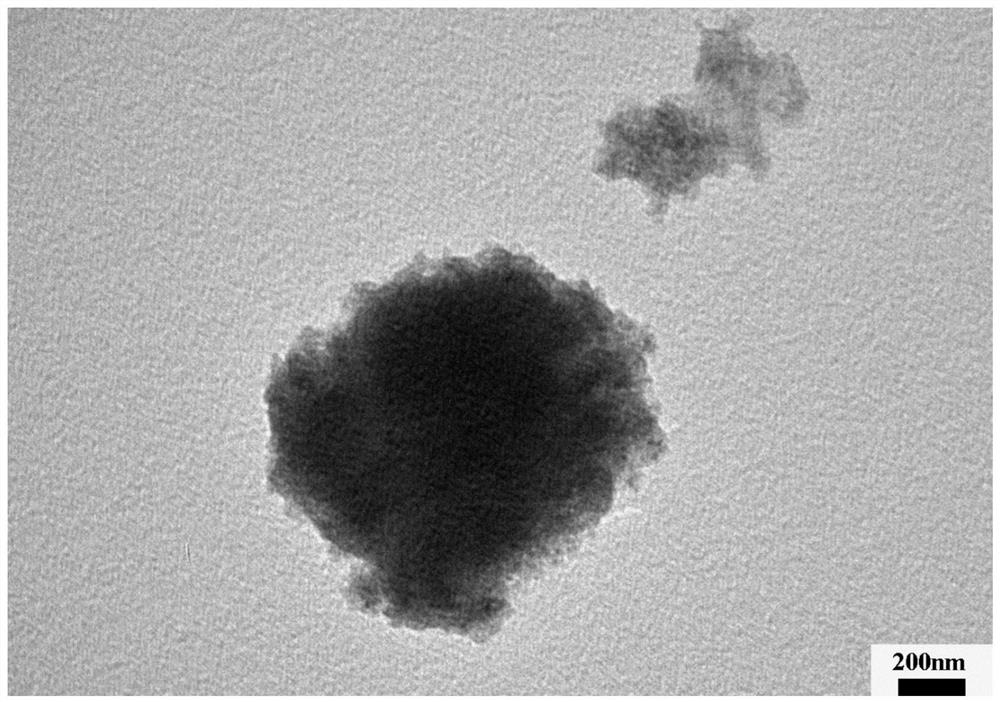

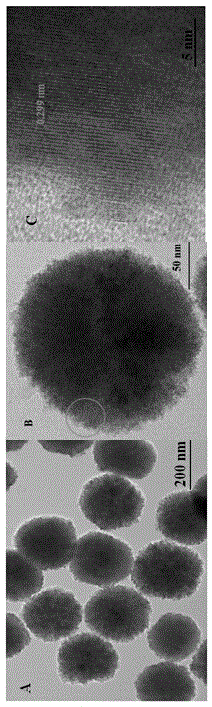

Ferric oxide nano-cluster mimic enzyme, preparation method and method for rapid detection of lactic acid

ActiveCN105129863BParticles have a large specific surface areaExcellent peroxidase-like activityMaterial nanotechnologyAnalysis by subjecting material to chemical reactionPeroxidaseMedical diagnosis

The invention discloses a ferroferric oxide nanocluster mimetic enzyme, a preparation method and a method for rapid detection of lactic acid with the ferroferric oxide nanocluster mimetic enzyme. The mimetic enzyme is a cluster-shaped loose particle formed by self-assembly of fine ferroferric oxide nanocrystals, and has a large specific surface area. The preparation method of the mimetic enzyme includes the steps of: dissolving ferric trichloride and anhydrous sodium acetate in ethylene glycol, then adding deionized water and performing stirring to form a uniformly dispersed solution; loading the solution obtained in step A into a hydrothermal reaction kettle, and putting the kettle into an oven heated to 160DEG C-200DEG C to react; and carrying out washing and vacuum drying, thus obtaining a solid sample. The invention not only provides an effective mimetic peroxidase material, but also establishes a new high selectivity method for simple and sensitive detection of lactic acid, and the method can be widely applied to clinical medical diagnosis and food safety monitoring.

Owner:兰州创力测控技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com