Ferric oxide nano-cluster mimic enzyme, preparation method and method for rapid detection of lactic acid

A technology of ferric tetroxide and nanoclusters, which is applied in the fields of nanotechnology and analysis and detection, can solve the problems of expensive equipment, low specificity, and easy interference, and achieves excellent peroxidase-like activity and high simulated peroxidation. The effect of enzyme catalytic ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1- 4

[0040] Preparation of embodiment 1-ferric oxide nanocluster mimetic enzyme:

[0041] 1) Dissolve 2.5mmol ferric chloride and 15mmol anhydrous sodium acetate in 40mL ethylene glycol, then add 0.54mL deionized water and stir to form a uniformly dispersed solution;

[0042] 2) Put the solution obtained in step 1 into a hydrothermal kettle, put it into an oven heated to 180°C to react for 12 hours, and then cool to room temperature with the furnace;

[0043]3) Pour out the supernatant in the reaction kettle, take out the precipitated product, wash with ethanol and deionized water three times respectively, and dry in a vacuum oven at 60°C for 10 hours to obtain a solid sample that is ferric oxide nanoclusters .

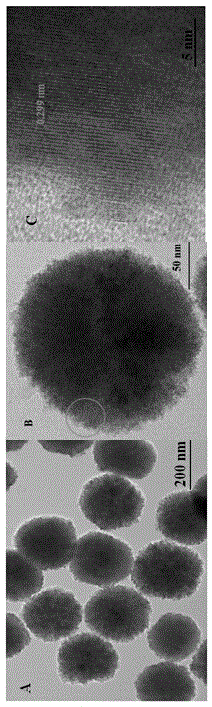

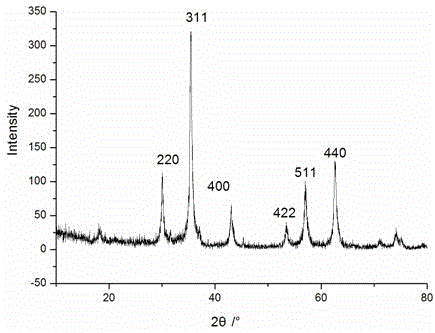

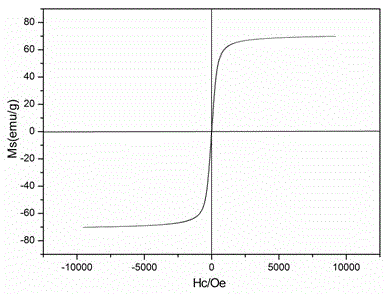

[0044] The morphology, structure and magnetic properties of the obtained Fe3O4 nanoclusters were characterized as follows: Figure 1-3 Shown:

[0045] From figure 1 (A) Fe3O4 nanoclusters are observed in transmission electron microscope composed of many small Fe 3 o ...

Embodiment 2-6

[0048] Examples 2-6, preparation of iron ferric oxide nanocluster mimetic enzymes: the steps are the same as in Example 1, and the specific amounts of raw materials and reaction conditions are shown in Table 1.

[0049]

Embodiment 2

[0050] The morphological characterization of the iron ferric oxide nanoclusters obtained under the specific reaction conditions of embodiment 2 and embodiment 4 are respectively as follows Figure 4 (A) and Figure 4 (B), where Figure 4 The insets in (A) and (B) are selected high-magnification TEM images of a Fe3O4 nanocluster.

[0051] From Figure 4 It can be seen that the average particle size of the iron ferric oxide nanoclusters obtained under the specific reaction conditions of embodiment 2 and embodiment 4 is about 40nm and 130nm respectively, and these two kinds of ferric oxide nanoclusters are still composed of many very small Fe 3 o 4 Cluster-like loose particles formed by self-assembly of nanocrystals.

[0052] "Characterization of Ferric Oxide Nanoclusters Mimicking Peroxidase Properties"

[0053] Mix 100 μL of 1 mg / mL ferric oxide nanocluster simulated enzyme stock solution, 100 μL of 100 μM H 2 o 2 Aqueous solution and 100 μl ethanol solution of 3,3',5,5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com