Fe-doped TiO2 nanotube photocatalyst, and preparation method and application thereof

A technology of photocatalysts and nanotubes, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve complex preparation processes and processes, small specific surface area, nanometer No secondary pollution, large specific surface area, and many adsorption sites can be achieved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Weigh 1.0g P-25TiO 2 powder and 0.0505g of Fe(NO 3 ) 3 9H 2 O, added to 16.0mL of 10mol / L NaOH solution, magnetically stirred for 0.5h, transferred to a polytetrafluoroethylene beaker, reacted at 105°C for 24h, removed and cooled to room temperature, washed with distilled water until neutral. Soak in 0.1mol / L hydrochloric acid for 0.5h, wash again until neutral, dry at 60°C, calcinate in a muffle furnace at 550°C for 2h, and grind to obtain Fe-doped nanotube TiO with an atomic doping amount of 1%. 2 catalyst. The above P-25TiO 2 Powder was purchased from Degussa Corporation, New Jersey. The TiO 2 Powder specific surface area is 50m 2 / g, the average particle size is 21nm, anatase and rutile account for 80% and 20% of the total mass respectively.

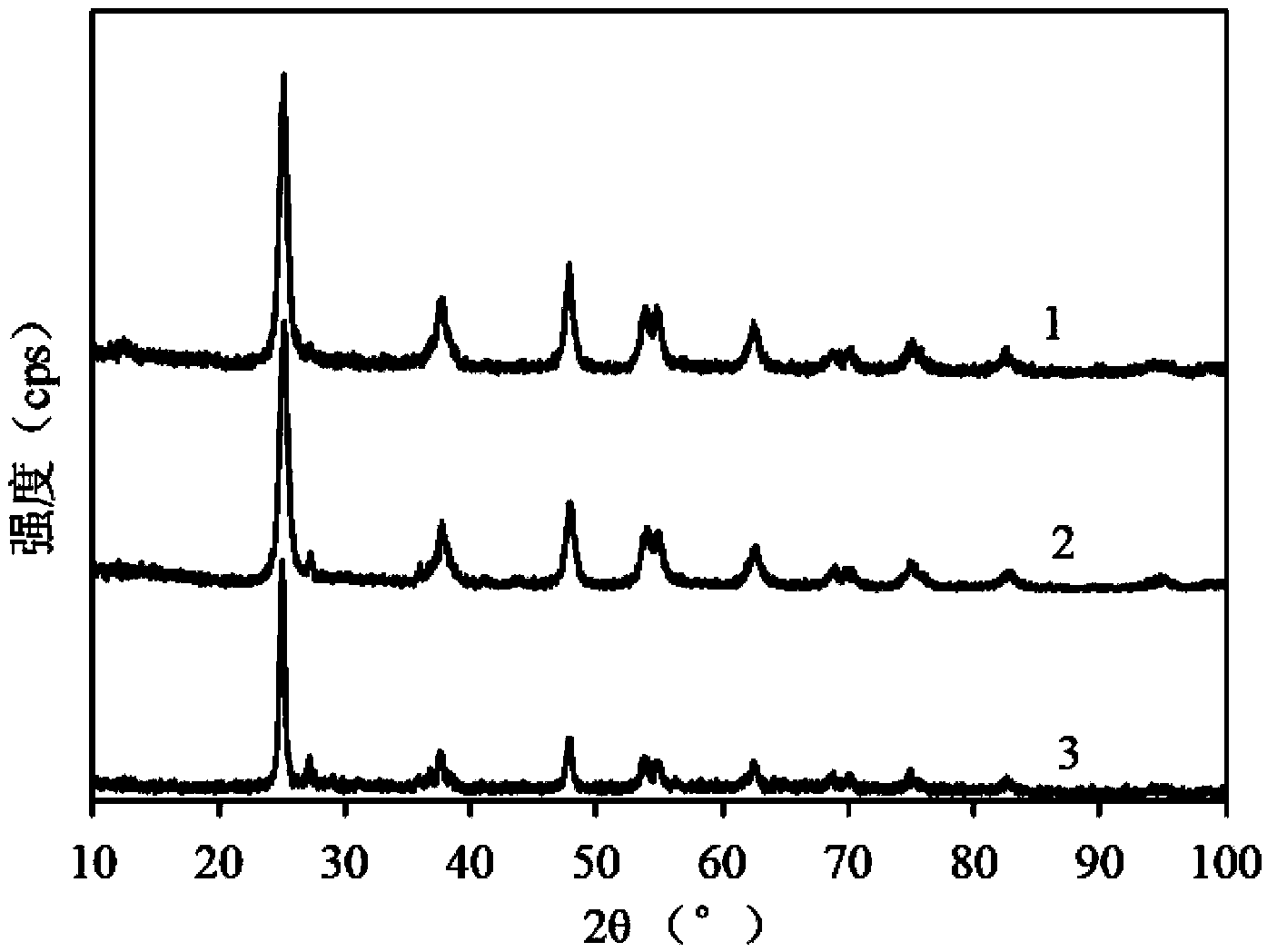

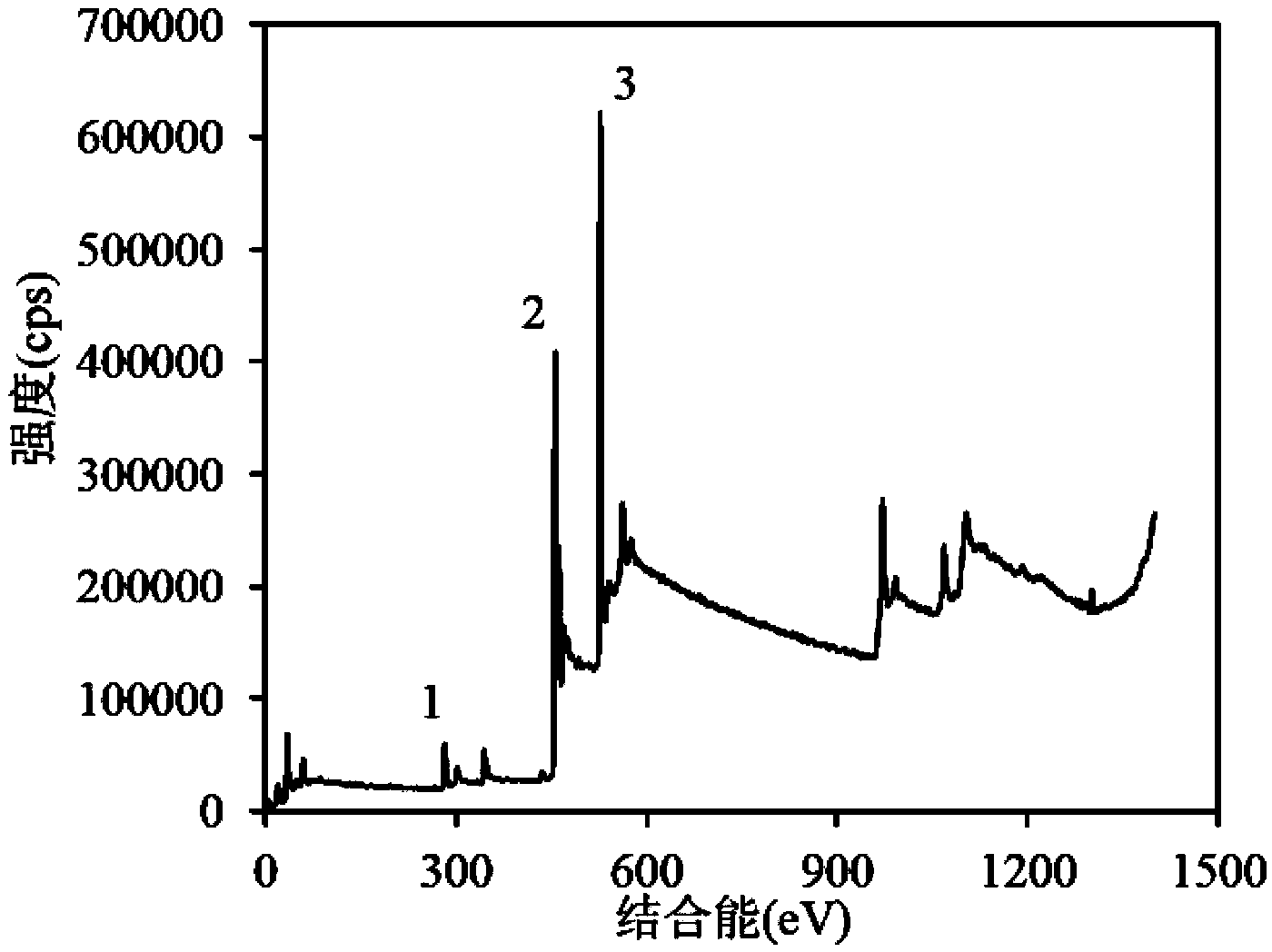

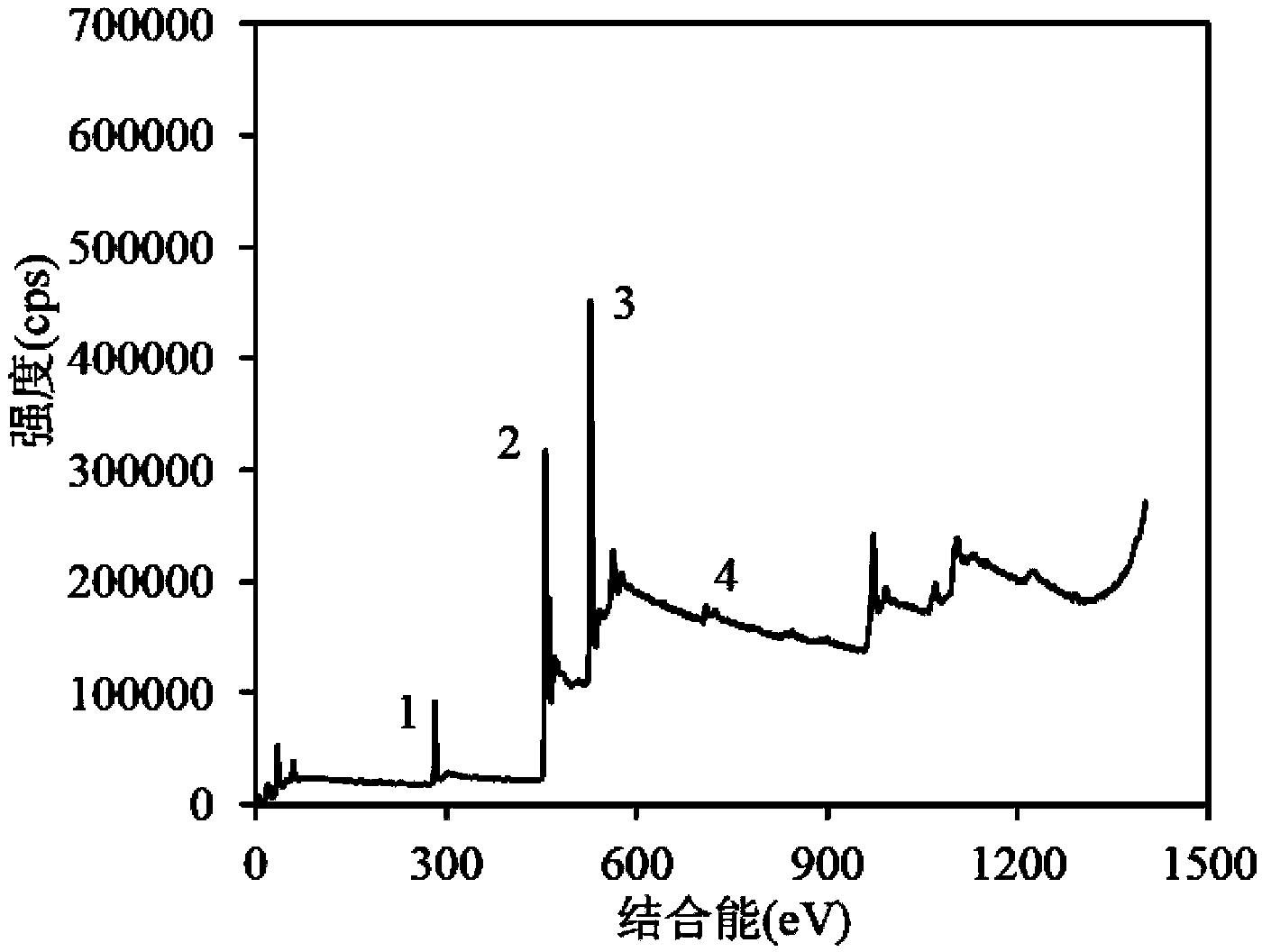

[0034] Analysis of calcined Fe-doped nanotube TiO at 550°C using Rigaku Dmax-RB rotating anode diffractometer (X-ray diffraction, XRD) 2 Crystal phase (Cu Kα target, λ=0.1506nm); ( figure 1 ), the results show that t...

Embodiment 2

[0037] Weigh 1.0g P-25TiO 2 powder and 0.0505g of Fe(NO 3 ) 3 9H2 O, added to 16.0mL of 10mol / L NaOH solution, magnetically stirred for 0.5h, transferred to a polytetrafluoroethylene beaker, reacted at 105°C for 24h, removed and cooled to room temperature, washed with distilled water until neutral. Soak in 0.1mol / L hydrochloric acid for 0.5h, wash again until neutral, dry at 60°C, calcinate in a muffle furnace at 450°C for 2h, and grind to obtain Fe-doped nanotube TiO with an atomic doping amount of 1%. 2 catalyst. The above P-25TiO 2 Powder was purchased from Degussa Corporation, New Jersey. The TiO 2 Powder specific surface area is 50m 2 / g, the average particle size is 21nm, anatase and rutile account for 80% and 20% of the total mass respectively.

[0038] Analysis of calcined Fe-doped nanotube TiO at 450°C using Rigaku Dmax-RB rotating anode diffractometer (X-ray diffraction, XRD) 2 Crystal phase (Cu Kα target, λ=0.1506nm); ( figure 1 ), the results show that the...

Embodiment 3

[0041] Weigh 1.0g P-25TiO 2 powder and 0.0505g of Fe(NO 3 ) 3 9H 2 O, added to 16.0mL of 10mol / L NaOH solution, magnetically stirred for 0.5h, transferred to a polytetrafluoroethylene beaker, reacted at 105°C for 24h, removed and cooled to room temperature, washed with distilled water until neutral. Soak in 0.1mol / L hydrochloric acid for 0.5h, wash again until neutral, dry at 60°C, calcinate in a muffle furnace at 500°C for 2h, and grind to obtain Fe-doped nanotube TiO with an atomic doping amount of 1%. 2 catalyst. The above P-25TiO 2 Powder was purchased from Degussa Corporation, New Jersey. The TiO 2 Powder specific surface area is 50m 2 / g, the average particle size is 21nm, anatase and rutile account for 80% and 20% of the total mass respectively.

[0042] Analysis of calcined Fe-doped nanotube TiO at 500℃ using Rigaku Dmax-RB rotating anode diffractometer (X-ray diffraction, XRD) 2 Crystal phase (Cu Kα target, λ=0.1506nm); ( figure 1 ), the results show that th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com