A kind of γ-oryzanol embedding solution and preparation method and instant milk powder and preparation method

An oryzanol and embedding solution technology, applied in the directions of vitamin-containing food ingredients, dairy products, milk preparations, etc., can solve the problems of low γ-oryzanol content, floating γ-oryzanol, low emulsifier content, etc., and achieves low heat sensitivity loss. , the effect of high activation energy and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

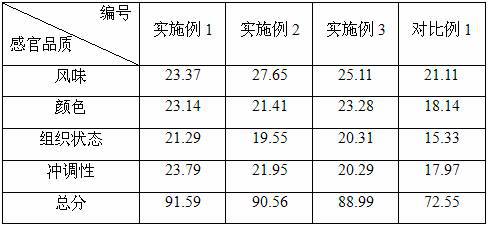

Examples

preparation example Construction

[0047] The preparation method of the γ-oryzanol aqueous solution is as follows: mixing 50g γ-oryzanol and 25g ascorbyl palmitate in a high-purity nitrogen atmosphere, then adding 1kg of water, heating to 80° C., then adding 25g ascorbyl palmitate, At 80°C, with a stirring speed of 20 r / min, keep stirring for 3 minutes, and after cooling to 50°C, continue to keep stirring for 25 minutes at 50°C with a stirring speed of 20 r / min, and adjust the pH value of the solution to 5.0 to obtain Aqueous solution of γ-oryzanol 1.

[0048] The preparation method of the wall material liquid is as follows: add 100 g of dextrin, 80 g of maltodextrin and 80 g of soluble starch to 1 kg of water, and under 25 MPa, homogenize for 5 minutes to obtain wall material liquid 1.

[0049] A kind of preparation method embodiment 1 of γ-oryzanol embedding solution

[0050] Mix 1.1 kg of γ-oryzanol aqueous solution 1 with a heated temperature of 60° C. and 1.26 kg of wall material solution 1, and homogeniz...

Embodiment 1

[0054] Made from 7.5kg of fresh milk and 2.36kg of γ-oryzanol Embedding Solution 1.

[0055] A kind of preparation method embodiment 1 of instant milk powder

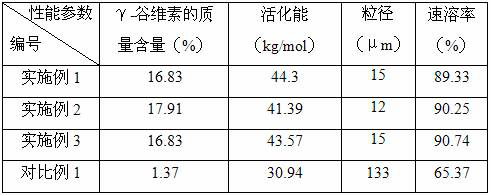

[0056] 7.5kg of fresh milk and 2.36kg of γ-oryzanol embedding solution 1 were mixed and homogenized at 25MPa for 15min, sterilized at 75°C for 20min, and concentrated to 25% of the total mass at 35°C and 65Pa. The material speed is 8kg / h, the air inlet temperature is 230℃, the air outlet temperature is 110℃, and the wind speed is 3.8m 3 / min, spray drying, freeze for 35 min at -15°C, seal and perform ball milling and ultra-fine pulverization to an average particle size of 15 μm at a feeding rate of 15kg / h at -15°C to obtain instant milk powder 1.

[0057] A kind of γ-oryzanol embedding solution embodiment 2

[0058] Homogenized by 1.1kg γ-oryzanol aqueous solution and 1.18kg wall material liquid; Described γ-oryzanol aqueous solution is formed by mixing 60g γ-oryzanol, 40g dibutylhydroxytoluene and 1kg water; Describe...

Embodiment 2

[0062] Mix 1.1 kg of γ-oryzanol aqueous solution 2 with a heated temperature of 90° C. and 1.18 kg of wall material liquid 2, and homogenize for 7 minutes at 20 MPa to obtain γ-oryzanol embedding solution 2.

[0063] The method for detecting the embedding rate of the γ-oryzanol embedding solution is the same as that in Example 1.

[0064] After testing, the embedding rate of the γ-oryzanol embedding solution obtained in the embodiment of the present invention was 40.37%.

[0065] A kind of instant milk powder embodiment 2

[0066] It is made of 7.5kg fresh milk and 2.28kg γ-oryzanol embedding solution 2.

[0067] A kind of preparation method embodiment 2 of instant milk powder

[0068] 7.5kg of fresh milk and 2.28kg of γ-oryzanol embedding solution 2 were mixed and homogenized for 20min at 20MPa, sterilized for 15min at 70°C, concentrated to 20% of the total mass at 30°C and 70Pa, and then, in The feed rate is 10kg / h, the air inlet temperature is 220°C, the air outlet tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com