Emergency treatment apparatus applicable to catalytic oxidation of high-risk wastewater

A technology for emergency treatment and catalytic oxidation, which is used in oxidized water/sewage treatment, water/sewage treatment, special compound water treatment, etc. The effect of high reaction efficiency and high wastewater treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

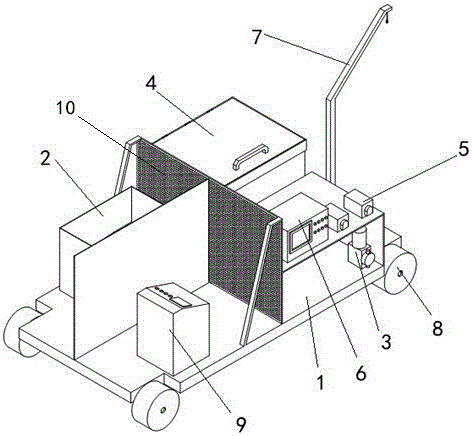

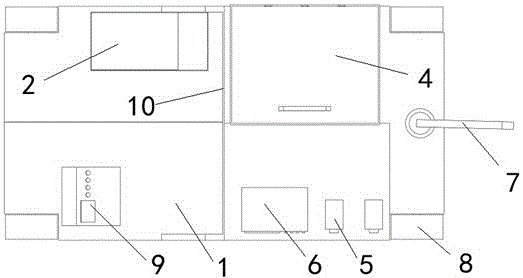

[0027] Embodiment 1: as figure 1 , 2 , 3, 4 and 5 show a kind of emergency treatment device suitable for catalytic oxidation of high-risk wastewater, said emergency treatment device includes a chassis 1, an oxidant storage area 2, a mixer 3, a catalytic reactor 4, a pressure water pump 5 and The three-way valve, the oxidant storage area 2, the mixer 3, the catalytic reactor 4 and the pressure water pump 5 are all fixedly installed on the chassis 1, and the waste water inlet pipe of the device is connected to the water inlet of the three-way valve through the pressure water pump 5 , the other water inlet of the three-way valve is connected to the oxidant storage area 2, the water outlet of the three-way valve is connected to the mixer 3, and the mixer 3 is connected to the water inlet 14 of the catalytic reactor 4 through a pipeline, and the catalytic reaction Device 4 is provided with drain port 15 to connect waste water drainpipe.

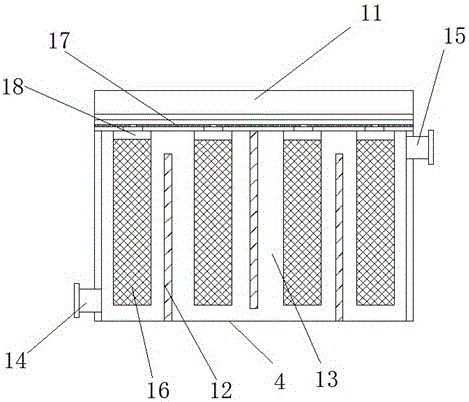

[0028] The catalytic reactor 4 is a close...

Embodiment 2

[0029] Embodiment 2: as image 3 , 4Shown in and 5, there is and only one catalytic reaction tank 16 in different reaction zones 13 on the same lifting rope 18, and there are and only one reaction lamp tubes 19 in different reaction zones 13 on the same lifting rope 18 One; when some components of the device break down, by directly extracting a group of lifting ropes 18, a lamp tube 19 or a catalytic reaction tank 16 is taken away in 13 in each reaction zone, and the lamp tube 19 and catalytic reaction tank 16 in each area The number is still the same, which is convenient for the stable progress of the catalytic oxidation reaction in each area, and does not affect the normal operation of the device while the maintenance work is in progress.

Embodiment 3

[0030] Embodiment 3: as image 3 , 4 Shown in and 5, the top of catalytic reaction tank 16 is connected on the pull rope 18 by top cover 17, and the tank body of catalytic reaction tank 16 is made up of cylindrical through hole screen cloth 20, and catalyzer is installed inside the tank body; The reaction tank is filled with a catalyst. In order to facilitate the full contact of the catalyst with the waste water and light in the tank body 4, the reaction tank body composed of a through-hole screen 20 is placed with a catalyst, and the catalyst reaction efficiency is high.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com