Application of Ca-based solid alkali heterogeneous catalyst in preparation of dimethyl carbonate

A heterogeneous catalyst, dimethyl carbonate technology, applied in catalyst activation/preparation, organic compound preparation, physical/chemical process catalyst, etc., can solve the difficulty of accurate control of hydrotalcite-like structure, loss of catalyst active component Ca , the catalyst preparation process is complicated and other problems, to achieve the effect of stable reuse performance, easy industrial scale-up, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

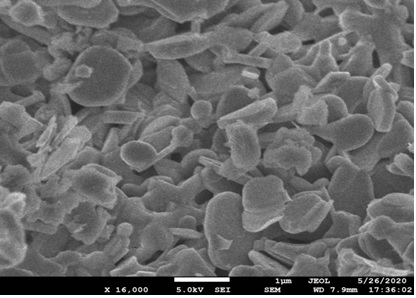

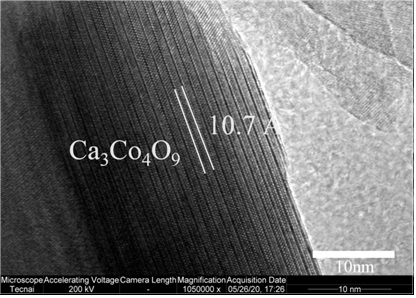

[0030] The catalyst was prepared by sol-gel method, and 10.12 g of Ca(NO 3 ) 2 ·4H 2 O, 16.63g of Co (NO 3 ) 2 ·6H 2 O salt, 19.21 g of citric acid, and 54 mL of deionized water were jointly transferred to a 250 mL three-necked flask, refluxed at 80 °C for 6 h under magnetic stirring, then heated to 105 °C, and 5.76 g of dispersant ethylene glycol was added, and the reflux stirring was continued. 6 h. Then the formed gel was dried in a blast drying oven at 110 °C for 12 h, ground into fine powder, and then calcined in a muffle furnace at 800 °C for 4 h at a heating rate of 2 °C / min to obtain Ca. 3 Co 4 O 9 catalyst.

[0031] Take 0.20g of catalyst and put it into the tank reactor, add 6.40g of methanol and 2.55g of propylene carbonate raw materials, and react under stirring at 60 ° C for 2 hours. After the product is cooled, it is analyzed by gas chromatography. The conversion rate of propylene carbonate is 57.5%. The yield of dimethyl ester was 53.9%.

Embodiment 2

[0033] The catalyst was prepared by sol-gel method, and 10.12 g of Ca(NO 3 ) 2 ·4H 2 O, 16.63g of Co (NO3 ) 2 ·6H 2 O salt, 28.82 g of citric acid, and 90 mL of deionized water were jointly transferred to a 250 mL three-necked flask, refluxed at 80 °C for 6 h under magnetic stirring, then heated to 105 °C, and 8.64 g of dispersant ethylene glycol was added, and the reflux stirring was continued. 6 h. Then the formed gel was dried in a blast drying oven at 110 °C for 12 h, ground into fine powder, and then calcined in a muffle furnace at 800 °C for 4 h at a heating rate of 2 °C / min to obtain Ca. 3 Co 4 O 9 catalyst.

[0034] Take 0.20g of catalyst and put it into the kettle reactor, add 6.40g of methanol and 2.55g of propylene carbonate raw materials, and react under stirring at 60 ° C for 2 hours. After the product is cooled, it is analyzed by gas chromatography. The yield of dimethyl ester was 52.7%.

Embodiment 3

[0036] The catalyst was prepared by sol-gel method, and 10.12 g of Ca(NO 3 ) 2 ·4H 2 O, 16.63g of Co (NO 3 ) 2 ·6H 2 O salt, 24.01 g of citric acid, and 90 mL of deionized water were jointly transferred to a 250 mL three-necked flask, refluxed at 80 °C for 6 h under magnetic stirring, then heated to 105 °C, and 9.0 g of dispersant ethylene glycol was added, and the reflux stirring was continued. 6 h. Then the formed gel was dried in a blast drying oven at 110 °C for 12 h, ground into fine powder, and then calcined in a muffle furnace at 800 °C for 4 h at a heating rate of 2 °C / min to obtain Ca. 3 Co 4 O 9 catalyst.

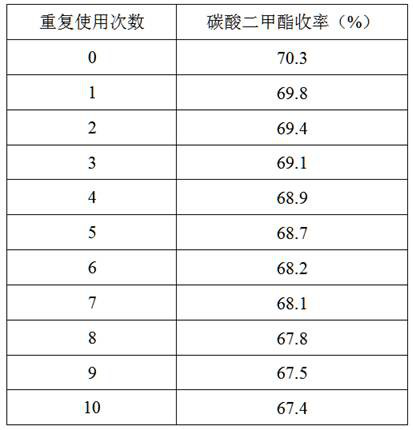

[0037] Take 0.20g of catalyst and put it into the tank reactor, add 6.40g of methanol and 2.55g of propylene carbonate raw materials, and react under stirring at 60 ° C for 2 hours. After the product is cooled, it is analyzed by gas chromatography. The conversion rate of propylene carbonate is 71.2%. The yield of dimethyl ester was 70.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com