Method for separating rare earth elements

A rare earth element and separation column technology, which is applied in the direction of improving process efficiency, can solve the problems of reduced effective utilization rate of extractant and low amount of rare earth adsorbed by resin, and achieves the effect of convenient operation and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

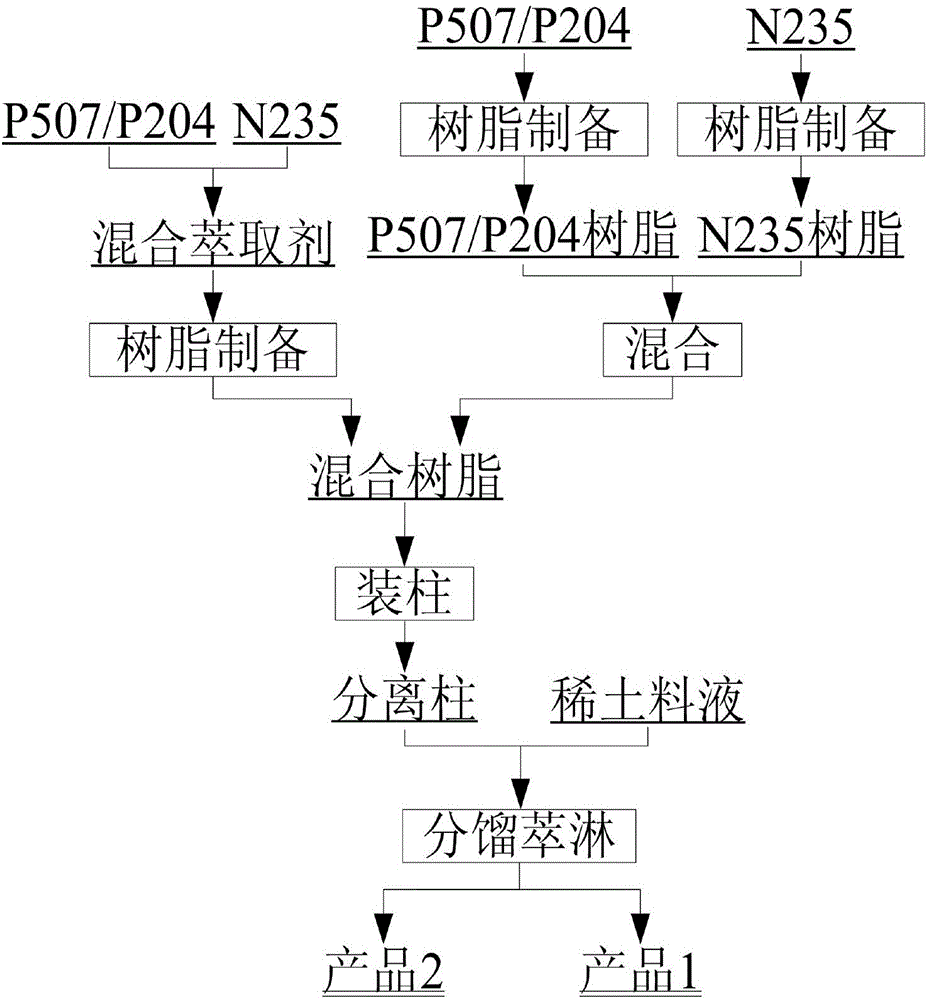

[0034] (1) Preparation of mixed resin:

[0035] A mixed resin prepared by mechanically mixing a single phosphorus extractant resin and a single amine extractant resin at a mass ratio of 1:0.1~5; or a composition of a phosphorus extractant and an amine extractant at a mass ratio of 1:0.1~5 The mixed resin prepared by the mixed extractant;

[0036] (2) Column packing:

[0037] The activated carbon adsorption material obtained in step (1) is loaded into an ion exchange column with a column diameter of 1 to 300 cm and a height-to-diameter ratio of 1 to 80:1 by a wet column packing method;

[0038] (3) Column separation:

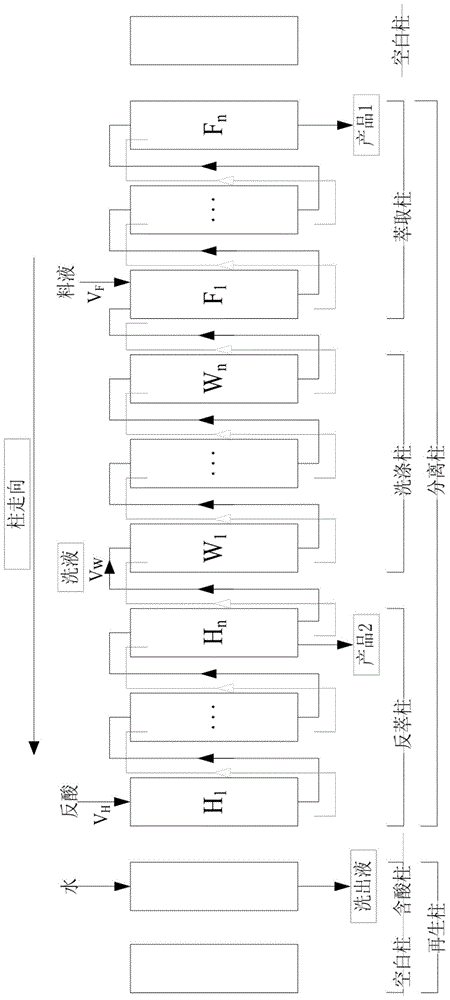

[0039] The ion-exchange column that step (2) packs obtains carries out multi-column series connection to obtain separation column, and the series connection method is as follows figure 2 , the separation column is divided into extraction column F, washing column W, and stripping column H according to the column connection section, and the direction of the colu...

Embodiment 1

[0046] Weigh dry 2-ethylhexyl phosphate mono-2-ethylhexyl ester (P507) resin and trialkyl tertiary amine (N235) resin in a mass ratio of 1:1 and mix evenly to form a mixed resin, add distilled water to fully soak the resin , and then packed into an ion-exchange column with a column diameter of 20 mm and a column height of 1000 mm by the wet column packing method, and the column packing height was 850 mm.

[0047] The separation process includes 15 separation columns, including 6 extraction columns, 6 washing columns and 3 stripping columns. The concentration of the rare earth material solution used in the experiment is 0.3mol / L, and the rare earth element is divided into Pr 3+ : 51.30%, Nd 3+ : 48.60%, other elements are -1 The flow rate from F 1 Flow through the separation column at 2.5cm·min with hydrochloric acid with a concentration of 5.0mol / L -1 The flow rate from H 1 Flow through the separation column, from H 3 The part of stripping acid flowing out at 1.40cm·min ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com