Acetophenone and 1-phenethyl alcohol separation method

A separation method and phenethyl alcohol technology are applied in the field of adsorption and separation of acetophenone and 1-phenethyl alcohol, can solve problems such as loss of β-cyclodextrin, and achieve the effects of stable performance, cheap raw materials and good separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

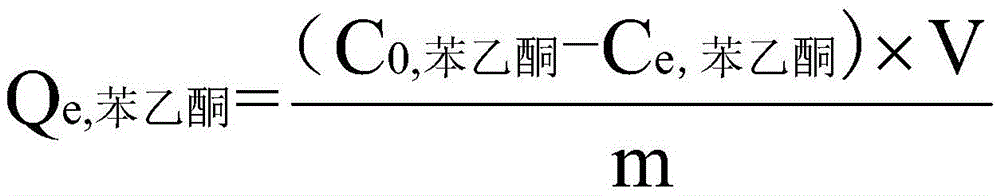

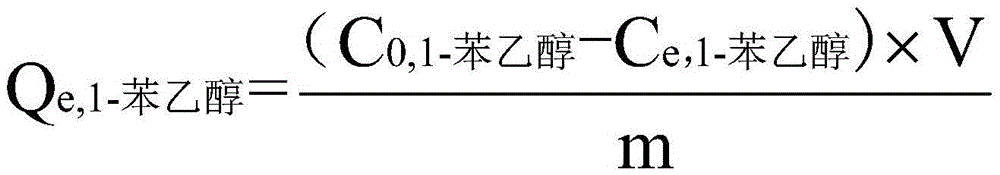

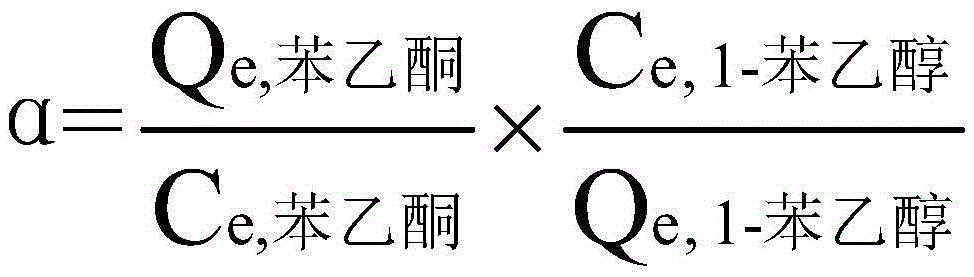

[0029] Add 30 mg of soluble starch-immobilized β-cyclodextrin polymer to 10 mL of an aqueous solution containing 5 mmol / L acetophenone and 5 mmol / L 1-phenylethanol, shake at 30 °C for 6 hours at normal pressure, and filter the residual liquid through the liquid Phase chromatography detects that the concentration of acetophenone and 1-phenylethanol in the residual liquid is 4.331mmol / L and 4.931mmol / L respectively, and the adsorption capacity of acetophenone and 1-phenylethanol is respectively 0.223mmol / L and 0.023mmol / L L, the separation factor was 11.04.

Embodiment 2

[0031] Add 30mg of soluble starch-immobilized β-cyclodextrin polymer to 10mL aqueous solution containing 10mmol / L acetophenone and 10mmol / L 1-phenylethanol, shake at 30°C for 6h under normal pressure, and filter the residual liquid through the liquid Phase chromatography detects that the concentration of acetophenone and 1-phenylethanol in the residual liquid is 8.668mmol / L and 9.881mmol / L respectively, and the adsorption capacity of acetophenone and 1-phenylethanol is respectively 0.444mmol / L and 0.063mmol / L L, the separation factor is 7.98.

Embodiment 3

[0033] Add 30 mg of soluble starch-immobilized β-cyclodextrin polymer to 10 mL of an aqueous solution containing 15 mmol / L acetophenone and 15 mmol / L 1-phenylethanol, shake at 30°C for 6 hours under normal pressure, and filter the residual liquid through the liquid Phase chromatography detects that the concentration of acetophenone and 1-phenylethanol in the residual liquid is 13.125mmol / L and 14.604mmol / L respectively, and the adsorption capacity of acetophenone and 1-phenylethanol is respectively 0.625mmol / L and 0.132mmol / L L, the separation factor is 5.26.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com