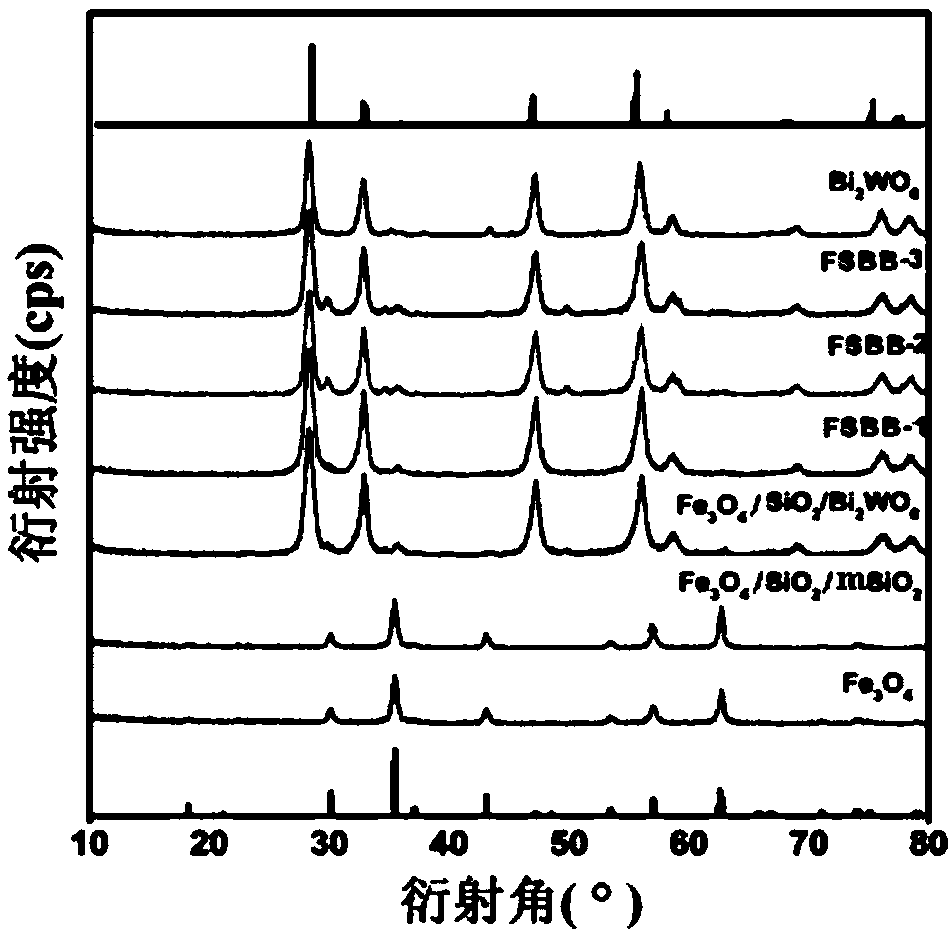

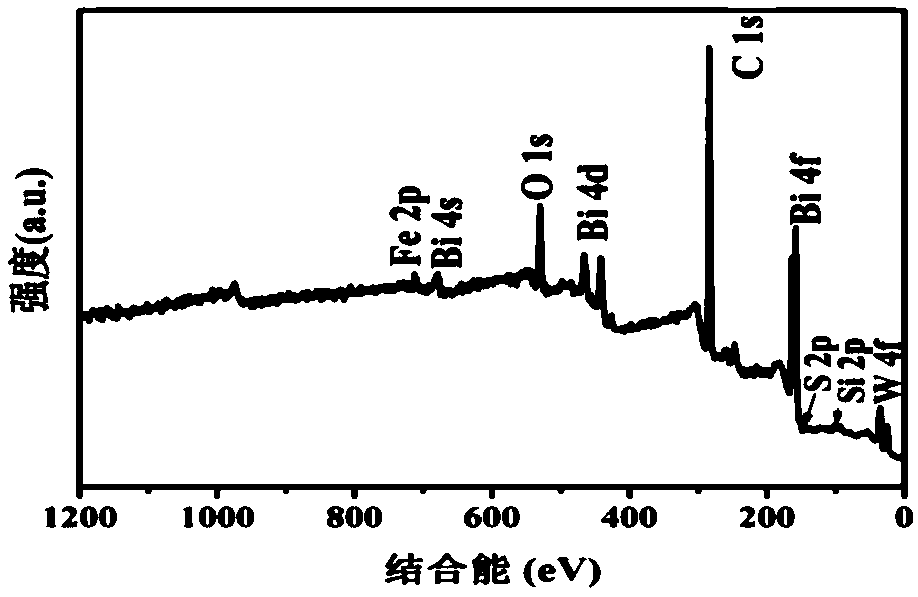

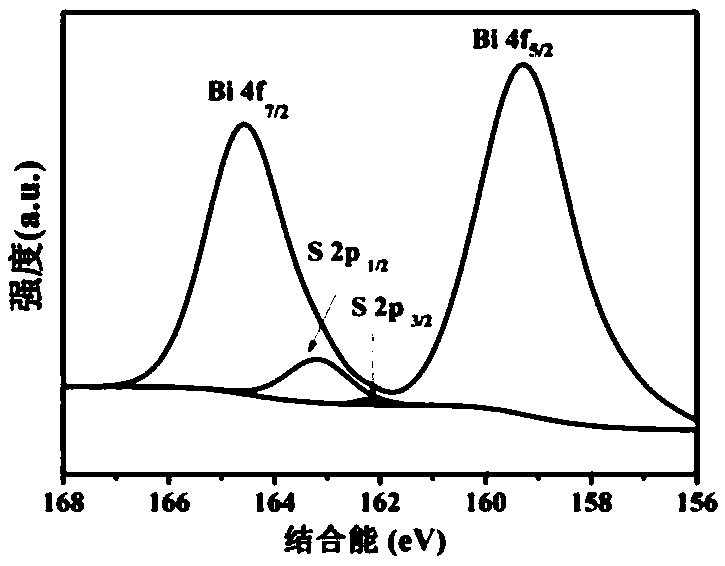

A kind of magnetic composite photocatalytic material and preparation method thereof

A composite photocatalytic and magnetic technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc. Narrow absorption range and other issues, to achieve the effect of wide visible light response range, mild conditions, and easy recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0064] The present invention also provides the preparation method of above-mentioned composite photocatalytic material: specifically comprise the following steps:

[0065] Step 1: Synthesis of nanomagnetic Fe by hydrothermal method 3 o 4 :

[0066] Step 1.1: Dissolve ferric chloride in ethylene glycol and mechanically stir for 20-40 minutes, continue to add sodium acetate and polyethylene glycol, and continue stirring for 1-3 hours to obtain mixture a, wherein the mass-volume ratio of ferric chloride to ethylene glycol is It is 1.35:40g / mL, the mass ratio of sodium acetate to polyethylene glycol is 3.6:1.0, and the mass ratio of ferric chloride to sodium acetate is 1.35:3.6;

[0067] Step 1.2: Transfer the mixture a to a stainless steel autoclave lined with polytetrafluoroethylene, and put it into an electric heating constant temperature blast drying oven, and react at 170-200°C for 5-10 hours to obtain mixture b ;

[0068] Step 1.3: naturally cool the mixture b to room te...

Embodiment 1

[0085] Step 1: Weigh 1.35g of ferric chloride and dissolve it in 40mL of ethylene glycol, stir with a rotary mechanical stirrer for 30min, then add 3.6g of sodium acetate and 1.0g of polyethylene glycol to it, and then use Stir with a rotary mechanical stirrer for 2 hours, then transfer to a 50mL stainless steel autoclave lined with polytetrafluoroethylene, put it in an electric heating constant temperature blast drying oven, and conduct a hydrothermal reaction at 180°C for 8 hours. After completion, let it cool down to room temperature naturally, then wash the obtained precipitate with water and alcohol successively, and dry it in vacuum at 80°C for 8h to obtain nano-magnetic Fe 3 o 4 ;

[0086] Step 2: Take the nano-magnetic Fe obtained in step 1 3 o 4 0.4g, then add 200mL of 0.1mol / L hydrochloric acid and ultrasonically disperse for 15min, then wash with deionized water until neutral, add 80mL of water and 320mL of ethanol, stir with a rotary mechanical stirrer, dropwise...

Embodiment 2

[0091] Step 1: Weigh 1.35g of ferric chloride and dissolve it in 40mL of ethylene glycol, stir with a rotary mechanical stirrer for 30min, then add 3.6g of sodium acetate and 1.0g of polyethylene glycol to it, and then use Stir with a rotary mechanical stirrer for 2 hours, then transfer to a 50mL stainless steel autoclave lined with polytetrafluoroethylene, put it in an electric heating constant temperature blast drying oven, and conduct a hydrothermal reaction at 180°C for 8 hours. After completion, let it cool down to room temperature naturally, then wash the obtained precipitate with water and alcohol successively, and dry it in vacuum at 80°C for 8h to obtain nano-magnetic Fe 3 o 4 ;

[0092] Step 2: Take the nano-magnetic Fe obtained in step 1 3 o 4 0.4g, then add 0.1mol / L hydrochloric acid 200mL and ultrasonically disperse for 15min, then wash with deionized water until neutral, add 80mL water and 320mL ethanol to it, stir with a rotary mechanical stirrer, slowly drop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com