Preparation method and application of oxygen-doped graphite-phase carbon nitride ozone catalyst

A graphite-phase carbon nitride and catalyst technology, which is applied in the field of water pollution control, can solve problems such as metal ion dissolution, environmental pollution, and catalyst activity reduction, and achieve the effects of accelerated degradation and removal, broad application prospects, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

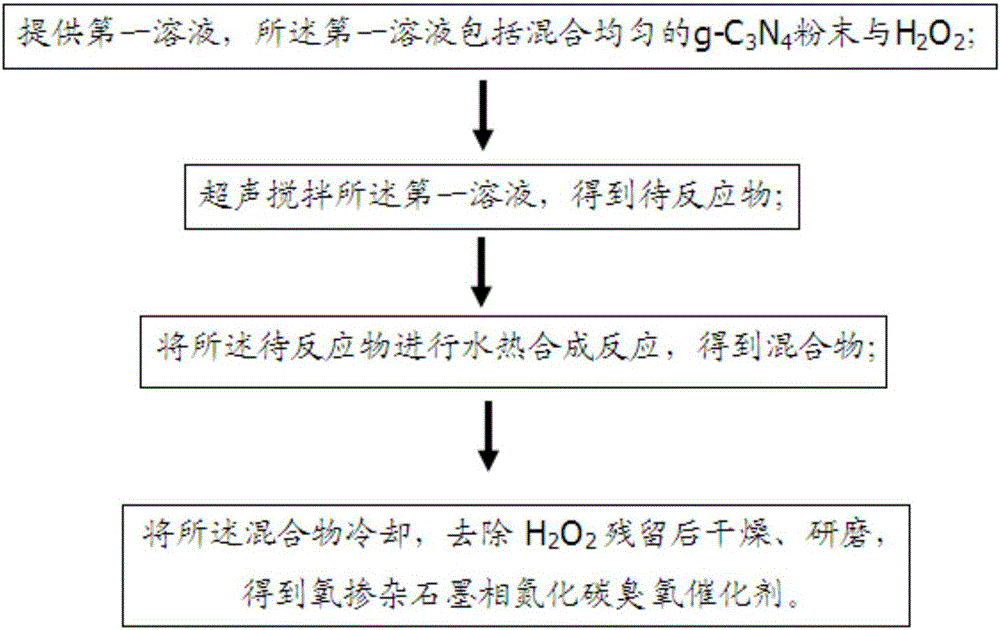

[0032] Such as figure 1 As shown, the preparation method of the oxygen-doped graphite phase carbon nitride ozone catalyst in the embodiment of the present invention includes the following steps:

[0033] Provide a first solution, the first solution comprising uniformly mixed g-C 3 N 4 Powder and H 2 O 2 ;

[0034] Stir the first solution ultrasonically to obtain the reactant;

[0035] Subjecting the reactant to a hydrothermal synthesis reaction to obtain a mixture;

[0036] Cool the mixture to remove H 2 O 2 After the residue is dried and ground, an oxygen-doped graphite phase carbon nitride ozone catalyst is obtained.

[0037] The g-C 3 N 4 The preparation method includes: roasting melamine and cooling to obtain g-C in the form of light yellow powder 3 N 4 , Grinding.

[0038] g-C 3 N 4 It has the typical characteristics of a semiconductor. It is non-toxic, high in quantum efficiency, and has good stability. It is a narrow band gap semiconductor. At the same time, it also has the advan...

Embodiment 1

[0044] g-C 3 N 4 Preparation

[0045] Weigh a certain amount of melamine into the crucible, put the crucible into the muffle furnace, and fire at a heating rate of 5°C / min and 550°C for 2 hours. After the crucible is cooled, take it out to obtain a light yellow powder of g-C 3 N 4 , Grind, set aside.

[0046] O / g-C 3 N 4 Preparation

[0047] Weigh 1g g-C 3 N 4 The powder is dissolved in 50ml 10mol / L H 2 O 2 In an ultrasonic cleaner, vigorously ultrasonically stir at 30°C for 2h, then transfer the sample to a hydrothermal reactor, place the reactor in an electric blast drying oven, and hydrothermally synthesize at 140°C for 10h, and wait until the reactor is cooled to Take it out after room temperature, centrifuge and wash the obtained sample several times until there is no H 2 O 2 Residue, and finally put the sample into an electric heating constant temperature blast drying oven, dry at 70 ℃, and grind to obtain the desired catalyst.

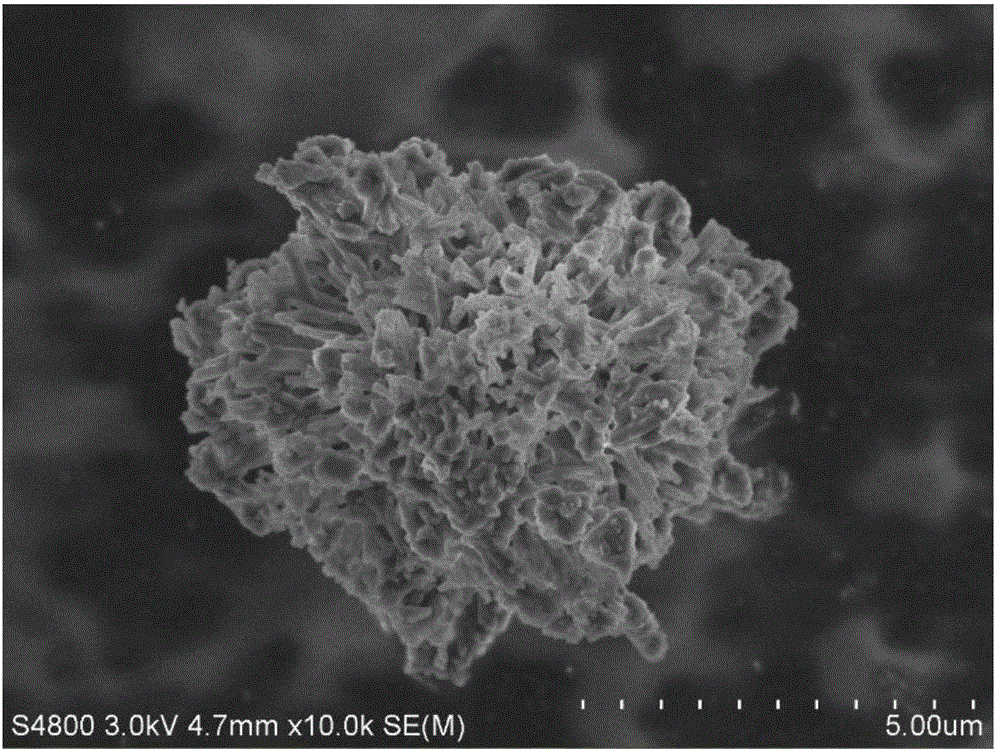

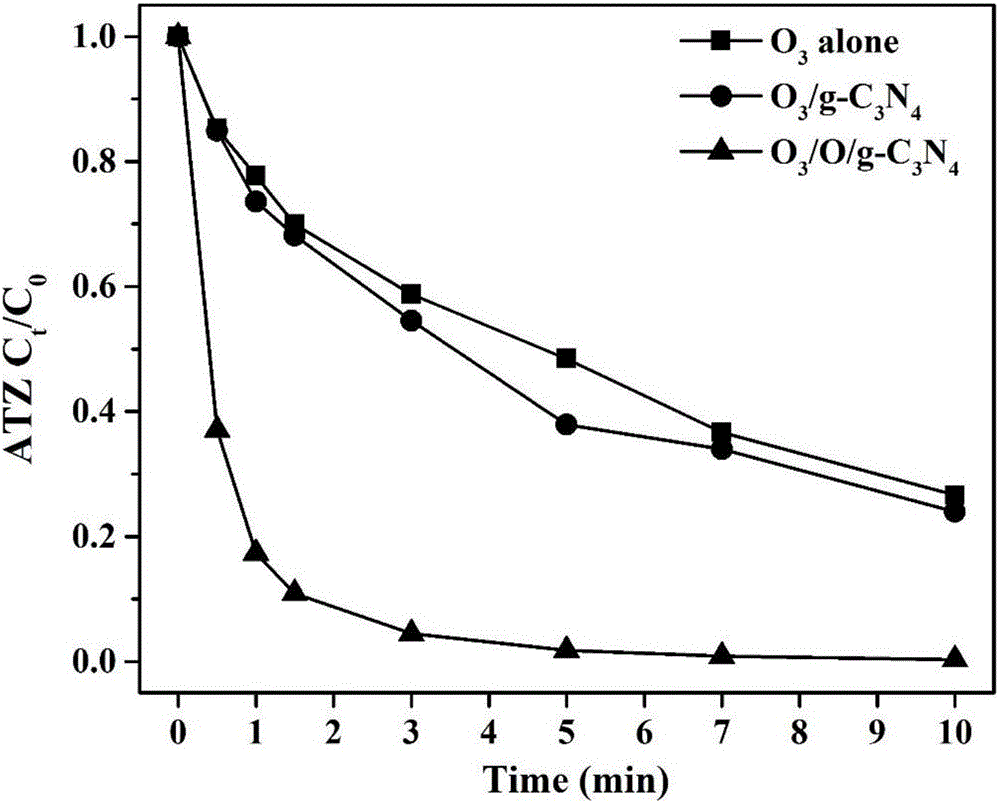

[0048] O / g-C prepared in Example 1 of the present...

Embodiment 2

[0052] g-C 3 N 4 Preparation

[0053] Weigh a certain amount of melamine into the crucible, put the crucible into the muffle furnace, and fire at a heating rate of 5°C / min and 500°C for 4 hours. After the crucible is cooled, take it out to obtain a light yellow powder of g-C 3 N 4 , Grind, set aside.

[0054] O / g-C 3 N 4 Preparation

[0055] Weigh 1g g-C 3 N 4 The powder is dissolved in 50ml5mol / L H 2 O 2 In an ultrasonic cleaner, stir vigorously at 40°C for 100 minutes, then transfer the sample to a hydrothermal reactor, place the reactor in an electric blast drying oven, and hydrothermally synthesize at 140°C for 6 hours, and wait until the reactor is cooled to Take it out after room temperature, centrifuge and wash the obtained sample several times until there is no H 2 O 2 Residue, finally put the sample into an electric heating constant temperature blast drying oven, dry at 80°C, and grind to obtain the desired catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com