Modified silicone rubber composition, textile fabric and application thereof

A technology of rubber composition and modified silicon, which is applied in the direction of one-component synthetic polymer rayon, textile and papermaking, water pollutants, etc. Advanced problems, to achieve the effect of good stability, stable reuse performance, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

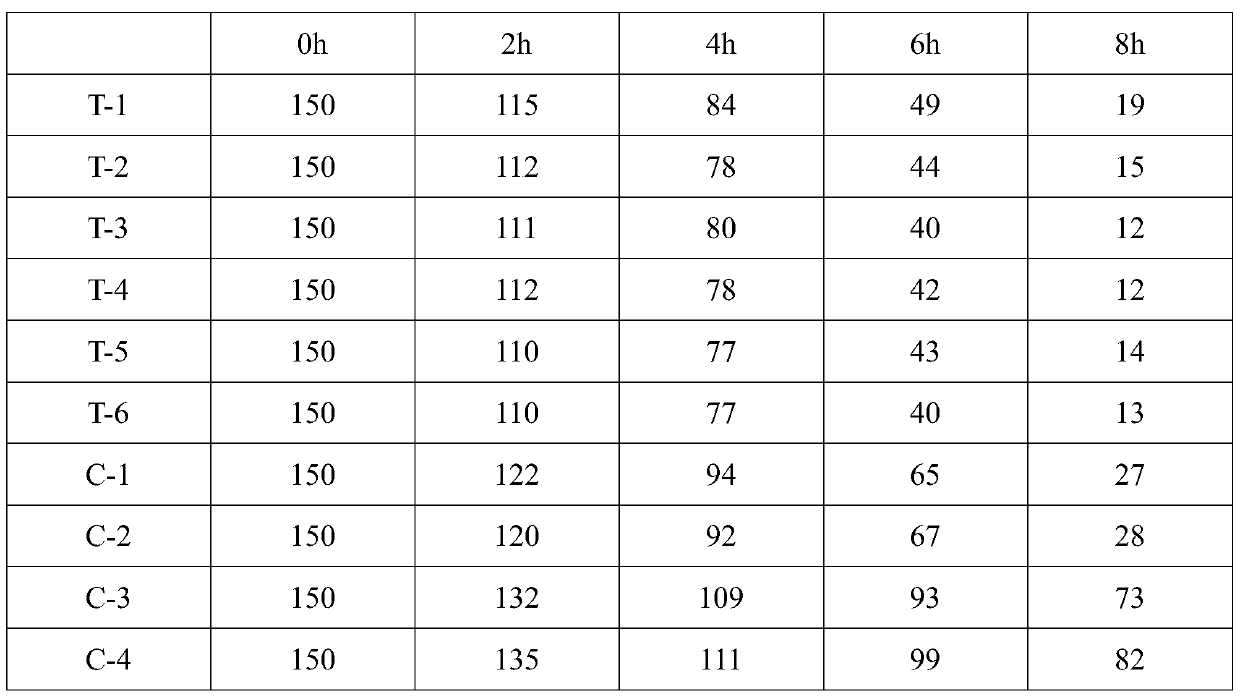

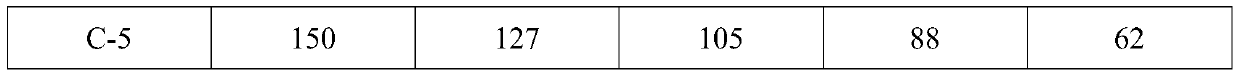

Image

Examples

Embodiment 1

[0039] Place the reactor in an environment of 0-5°C, add 1-aminoanthraquinone and fluorosilicon polymer A at a molar ratio of 1.9:1, and then add tetrahydrofuran and fluorosilicon polymer A which are 10 times the weight of fluorosilicon polymer A 2% 1-methylimidazole, stirred and reacted for 6 hours, then placed at 40°C and stirred for 2 hours, and THF was removed to obtain an anthraquinone-containing fluorosilicon compound, denoted as F-1.

Embodiment 2

[0041] Place the reactor in an environment of 0-5°C, add 2-aminoanthraquinone and fluorosilicon polymer B at a molar ratio of 2:1, and then add tetrahydrofuran and fluorosilicon polymer B that are 15 times the weight of fluorosilicon polymer B 2% 2-methylimidazole, stirred and reacted for 3 hours, then placed at 30° C. and stirred for 5 hours, removed tetrahydrofuran, and obtained anthraquinone-containing fluorosilicon compound, denoted as F-2.

Embodiment 3

[0043]Place the reactor in an environment of 0-5°C, add 1-amino-2-methylanthraquinone, fluorosilicon polymer C and 2-phenylimidazole by weight of 2% by weight of fluorosilicon polymer C at a molar ratio of 4:1 , and then added butyl acetate 15 times the weight of fluorosilicon polymer C, stirred for 3 hours, then placed at 30°C and stirred for 5 hours, removed butyl acetate, and obtained anthraquinone-containing fluorosilicon compound, denoted as F-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com