Method and device for preparing spherical silver powder by fractional step method

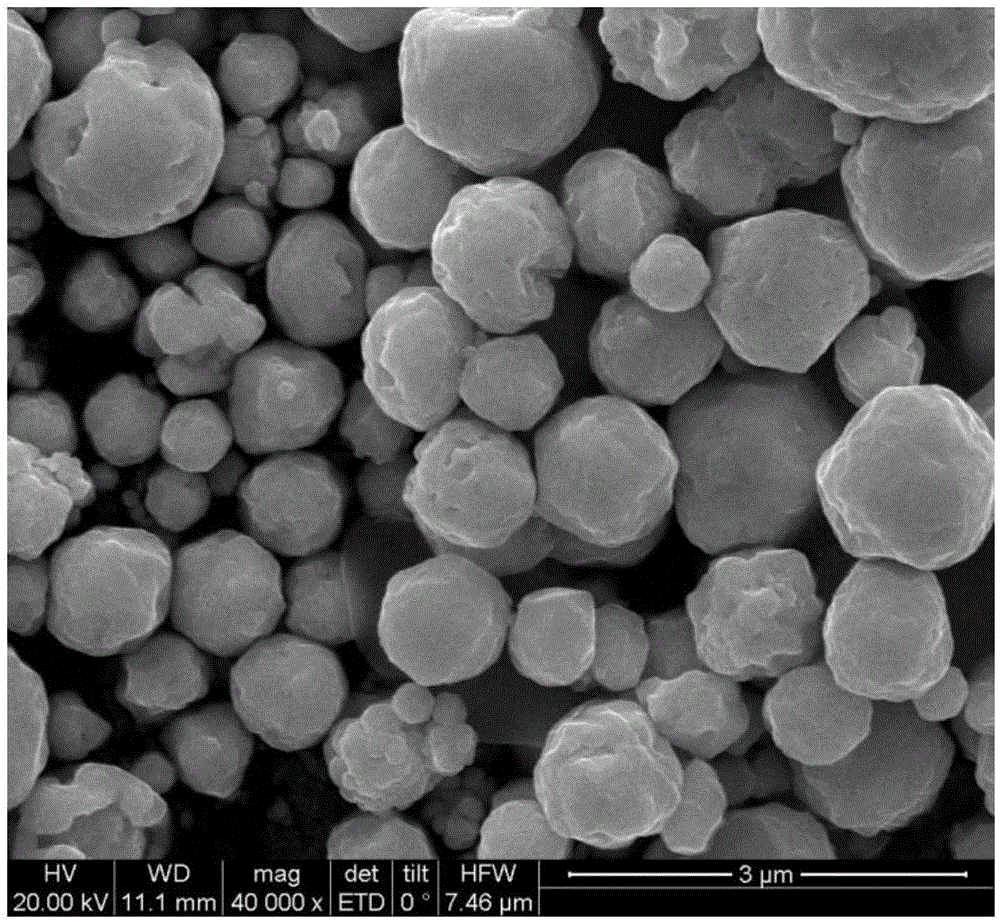

A step-by-step method and silver powder technology, which is applied in the chemical industry, can solve the problems of unstable spherical silver powder quality, poor sphericity and fluidity of silver powder, and achieve the effect of being suitable for large-scale production, superior electrical conductivity, and high performance indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

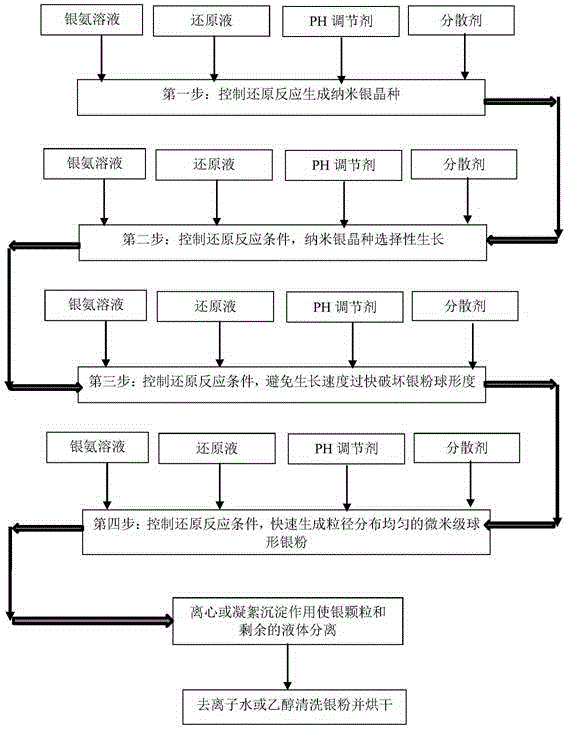

[0021] Such as figure 1 Shown, the invention provides a kind of step-by-step method for preparing spherical silver powder, comprising the steps:

[0022] 1) The step of controlling the reduction reaction to generate nano-silver seeds, weighing the first batch of silver ammonia solution and the first batch of reducing agent according to the mass ratio of 1:0.1, the concentration of silver ammonia solution is 7.3% Wt, and the concentration of reducing agent is 80ppm. Take by weighing the first batch of 20% Wt ammonia water according to the above-mentioned silver-ammonia solution mass ratio of 1:0.13, take the first batch of dispersant according to the above-mentioned silver-ammonia solution mass ratio of 1:0.2, and add the above-mentioned materials to the In a first reaction container, the reaction time is 0.02 minutes, and the pH regulator adjusts the pH value of the reaction solution to 9.3;

[0023] 2) The step of controlling the reduction reaction conditions to selectively ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com