Enhanced self-lubricating copper-based composite material and preparation method and application thereof

A copper-based composite material and self-lubricating technology, which is applied in the field of reinforced copper-based composite materials and its preparation, can solve the problems of high cost, uneven material density, complicated process and equipment, etc., and achieve good mechanical and wear resistance, The process and equipment are simple and the effect of saving preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] First weigh 5g of boron nitride powder with a median particle size of 0.5μm, 14g of pure titanium powder with a median particle size of 40μm, and 14g of pure copper powder with a median particle size of 40μm, add 40g of absolute ethanol, and roll ball mill for 3 hours , to obtain a uniform and stable slurry; then dry at 50-80°C for 2 hours, and sieve to obtain a mixture powder; place the mixture powder in a graphite crucible and sinter in a self-propagating sintering furnace to obtain a composite precursor powder; then pour the composite precursor powder into a hot-pressing mold for hot-pressing sintering at a sintering temperature of 900°C for 1 hour and a hot-pressing pressure of 25 MPa to obtain the desired self-lubricating copper-based composite material.

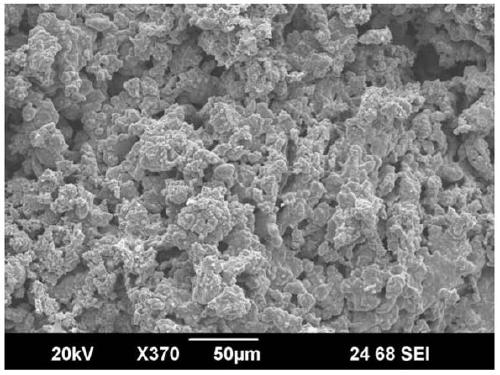

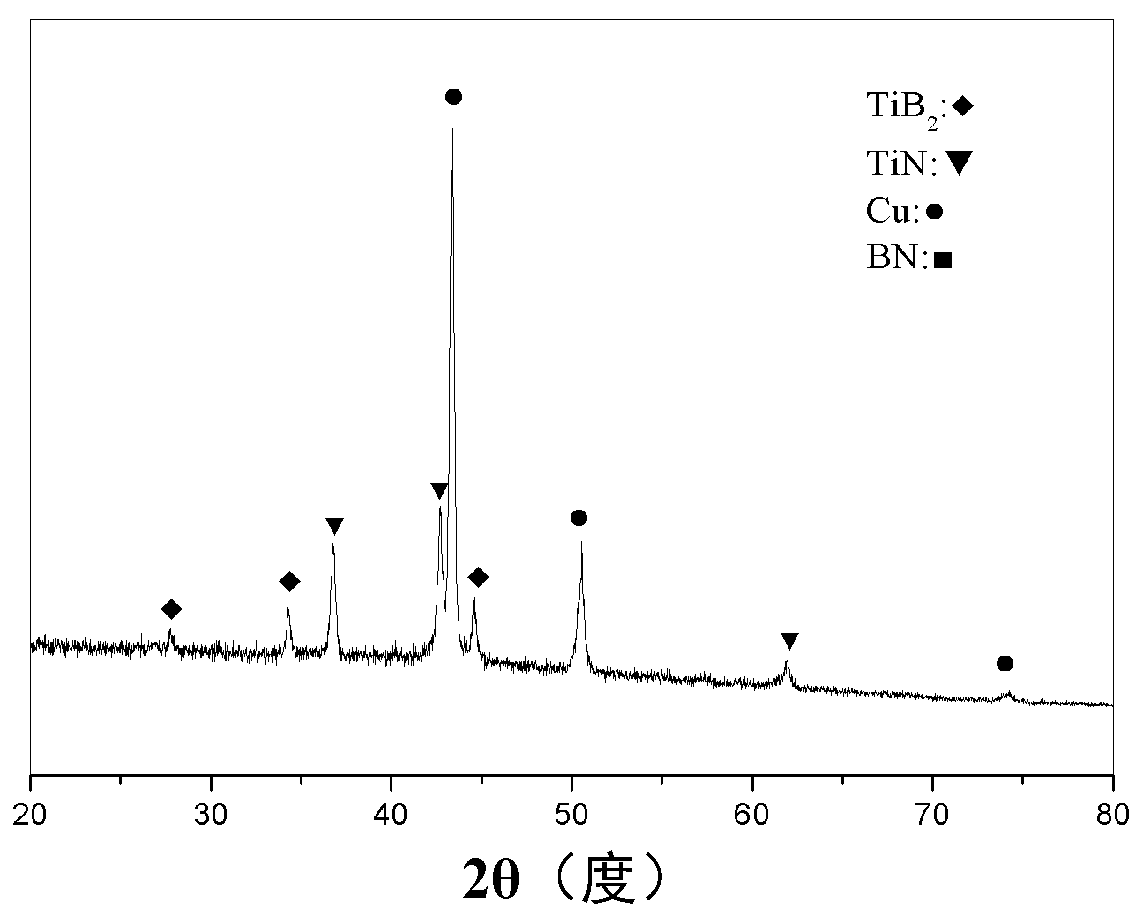

[0051] The powder morphology of the composite precursor powder prepared in this example is shown in figure 1 shown, phase composition see figure 2 shown. From figure 1 It can be seen that there are no exposed f...

Embodiment 2

[0053] First weigh 6g of boron nitride powder with a median particle size of 0.5μm, 14g of pure titanium powder with a median particle size of 40μm, and 24g of pure copper powder with a median particle size of 40μm, add 40g of absolute ethanol, and roll ball mill for 3 hours , to obtain a uniform and stable slurry; then dry at 50-80°C for 2 hours, and sieve to obtain a mixture powder; place the mixture powder in a graphite crucible and sinter in a self-propagating sintering furnace to obtain a composite precursor powder; then pour the composite precursor powder into a hot-pressing mold for hot-pressing sintering at a sintering temperature of 900°C for 1 hour and a hot-pressing pressure of 25 MPa to obtain the required self-lubricating copper-based composite material.

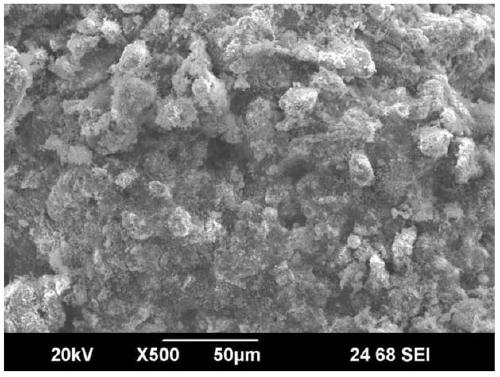

[0054] The powder morphology of the composite precursor powder prepared in this example is shown in image 3 shown, phase composition see Figure 4 shown. From image 3 It can be seen that there are a certain...

Embodiment 3

[0056] First weigh 5g of boron nitride powder with a median particle size of 0.5μm, 14g of pure titanium powder with a median particle size of 40μm, and 14g of pure copper powder with a median particle size of 40μm, add 40g of absolute ethanol, and roll ball mill for 3 hours , to obtain a uniform and stable slurry; then dry at 50-80°C for 2 hours, and sieve to obtain a mixture powder; then dry-press the prepared mixture powder, and the dry-press pressure is 20MPa; dry-press the blank The body is subjected to cold isostatic pressing at a pressure of 200 MPa; the body after cold isostatic pressing is subjected to self-propagating sintering to obtain a reinforced self-lubricating copper matrix composite.

[0057] The surface morphology of the composite material obtained in this embodiment is shown in Figure 5 shown, from Figure 5 It can be seen from the figure that the density of the composite material is high, showing a continuous Cu phase, but still a small amount of discret...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com