Method for preparing prenol by isomerizing 3-methyl-3-butene-1-ethanol

A technology of prenol and isomerization, which is applied in the field of preparing prenol, can solve the problems of expensive catalyst operation, equipment requirements and high risk, and achieve the effect of simple and stable composition, high safety and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

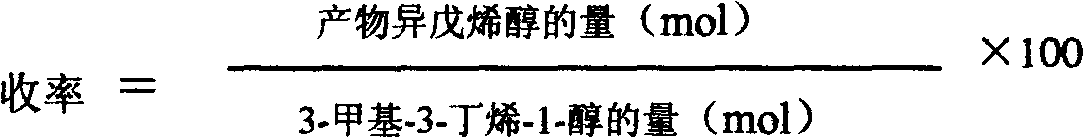

[0021] Example 1 Take 100g of 3-methyl-3-buten-1-ol (purity 98%), and sodium hydroxide aqueous solution (concentration 30%) 20g, add 250mL reaction flask and heat to 80 ℃ and stir for 3 hours. Then take the reaction solution, carry out rectification and separation, recover the reaction raw materials and remove part of the by-products, the purity of prenol is 98.25% after detection, and the yield is 30%. The recovered raw materials can be used to continue the reaction.

Embodiment 2

[0022] Example 2 has the same conditions as Example 1 but the catalyst is an aqueous solution of sodium carbonate (concentration: 30%). The purity of prenol is 98.15% and the yield is 27%.

Embodiment 3

[0023] Example 3 has the same conditions as Example 1, but the catalyst is potassium carbonate solid 20g, the purity of prenol is 98.32% after detection, and the yield is 35%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com