Multilayered filter screen

A filter screen and filter screen technology, which is applied in the direction of filtration and separation, dispersed particle filtration, fixed filter element filter, etc., can solve the problems that cannot meet the requirements of equipment assembly and use, short service life requires regular maintenance, and affects equipment working efficiency. Achieve the effect of reasonable design structure, long service life and strong toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments.

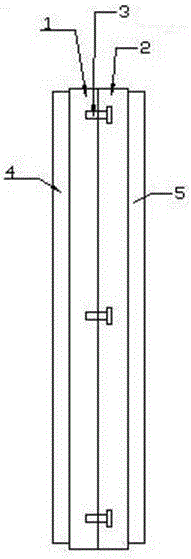

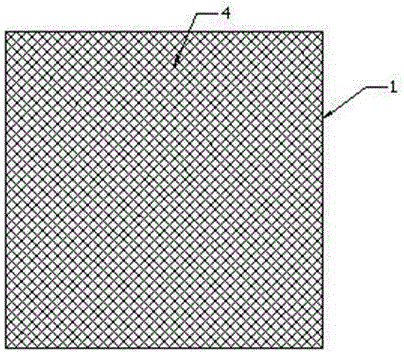

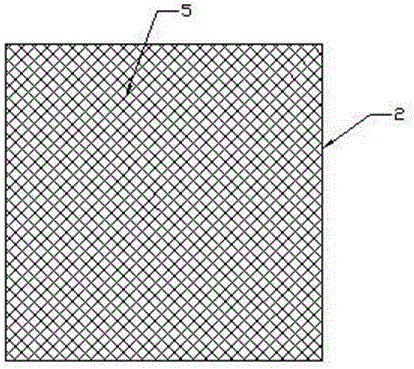

[0016] Such as figure 1 , figure 2 with image 3 The multi-layer filter shown includes a first rib frame 1 and a second rib frame 2 connected to the first rib frame 1, wherein the positioning screw is used between the first rib frame 1 and the second rib frame 2 3 connected, and the first rib frame 1 and the second rib frame 2 have the same structure and size, and the first filter screen 4 and the second filter screen 5 are respectively arranged on the first rib frame 1 and the second rib frame 2.

[0017] Further preferably, both the first filter screen 4 and the second filter screen 5 are filter screens woven with stainless steel wires, the weaving structure is stable and has strong corrosion resistance, wear resistance, high temperature resistance, and long service life; and The mesh diameter of the first filter screen 4 is smaller than ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com