Agricultural machinery lubricating oil and preparation method thereof

A lubricating oil and agricultural machinery technology, applied in the field of agricultural machinery lubricating oil and its preparation, can solve the problems of poor storage state of lubricating oil, wear, poor lubrication effect, etc., achieve strong weather resistance, high cost performance, and increase heat resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

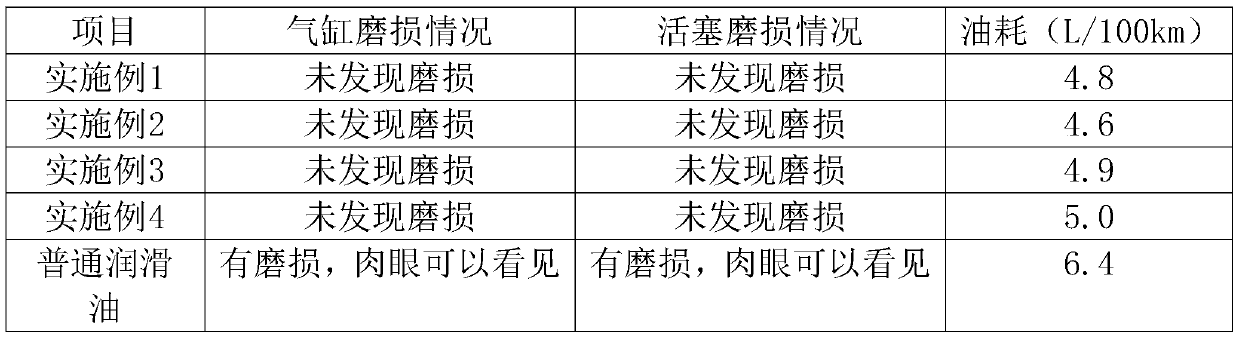

Examples

Embodiment 1

[0024] An agricultural machinery lubricating oil, consisting of the following raw materials in parts by weight: 60 parts of graphene, 45 parts of propolis extract, 30 parts of dodecanethiol, 120 parts of epoxy soybean oil, 1.8 parts of dodecanedioic acid, stearic acid 10 parts of magnesium, 7 parts of sodium lignosulfate, 7 parts of sodium potassium tartrate, 4 parts of diethanolamide cocoate.

[0025] The preparation method of described agricultural machinery lubricating oil, comprises the steps:

[0026] 1) Put the propolis extract, magnesium stearate and dodecanethiol into the reaction kettle in parts by mass, add deionized water 1.4 times the mass of the propolis extract at 31.5°C, grind for 20 minutes, and stir clockwise for 10 minutes , the stirring speed is 70r / min, and the viscous stirring liquid Q is obtained after the stirring is finished, which is stored in another device for subsequent use;

[0027] 2) Add dodecanedioic acid, viscous stirring liquid Q, and epoxidi...

Embodiment 2

[0030] An agricultural machinery lubricating oil, consisting of the following raw materials in parts by weight: 65 parts of graphene, 55 parts of propolis extract, 35 parts of dodecanethiol, 140 parts of epoxy soybean oil, 1.9 parts of dodecanedioic acid, stearic acid 11 parts of magnesium, 8.5 parts of sodium lignosulfate, 8.5 parts of sodium potassium tartrate, and 5 parts of diethanolamide cocoate.

[0031] The preparation method of described agricultural machinery lubricating oil, comprises the steps:

[0032] 1) Put the propolis extract, magnesium stearate and dodecanethiol into the reaction kettle in parts by mass, add deionized water 1.6 times the mass of the propolis extract at 32°C, grind for 23 minutes, and stir clockwise for 12 minutes , the stirring speed is 85r / min, and the viscous stirring liquid Q is obtained after the stirring is finished, and it is stored in another device for subsequent use;

[0033] 2) Add dodecanedioic acid, viscous stirring liquid Q, and ...

Embodiment 3

[0036] An agricultural machinery lubricating oil, consisting of the following raw materials in parts by weight: 63 parts of graphene, 50 parts of propolis extract, 32 parts of dodecanethiol, 130 parts of epoxy soybean oil, 1.9 parts of dodecanedioic acid, stearic acid 11 parts of magnesium, 8 parts of sodium lignosulfate, 8 parts of sodium potassium tartrate, 5 parts of diethanolamide cocoate.

[0037] The preparation method of described agricultural machinery lubricating oil, comprises the steps:

[0038] 1) Put the propolis extract, magnesium stearate and dodecanethiol into the reaction kettle in parts by mass, add deionized water 1.5 times the mass of the propolis extract at 32.5°C, grind for 22 minutes, and stir clockwise for 13 minutes , the stirring speed is 80r / min, and the viscous stirring liquid Q is obtained after the stirring is finished, which is stored in another device for subsequent use;

[0039]2) Add dodecanedioic acid, viscous stirring liquid Q, and epoxidiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com