Method and system for decomposing scheelite concentrate

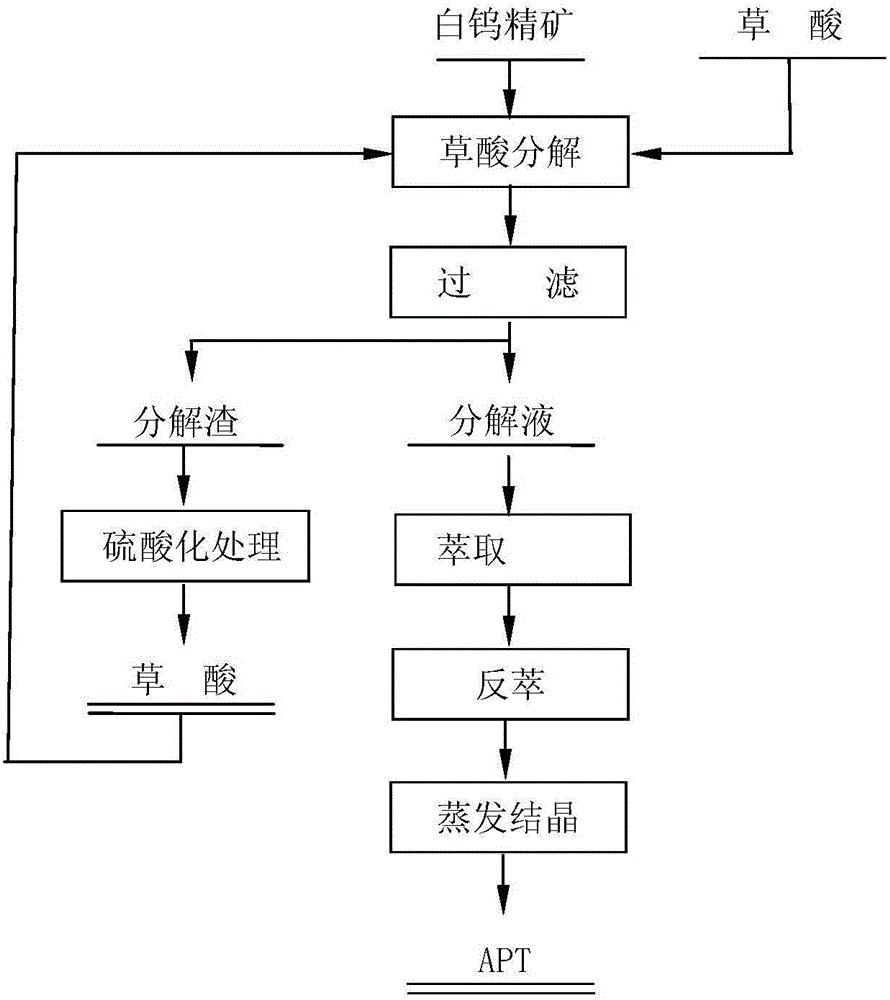

A technology for concentrate and scheelite, applied in the field of decomposing scheelite concentrate, can solve the problems of difficult separation of tungsten and phosphorus, reduce the decomposition cost of scheelite concentrate, and affect the quality of products by phosphorus, and achieve easy industrial-scale production and operation. The effect of strong performance, simple process and equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

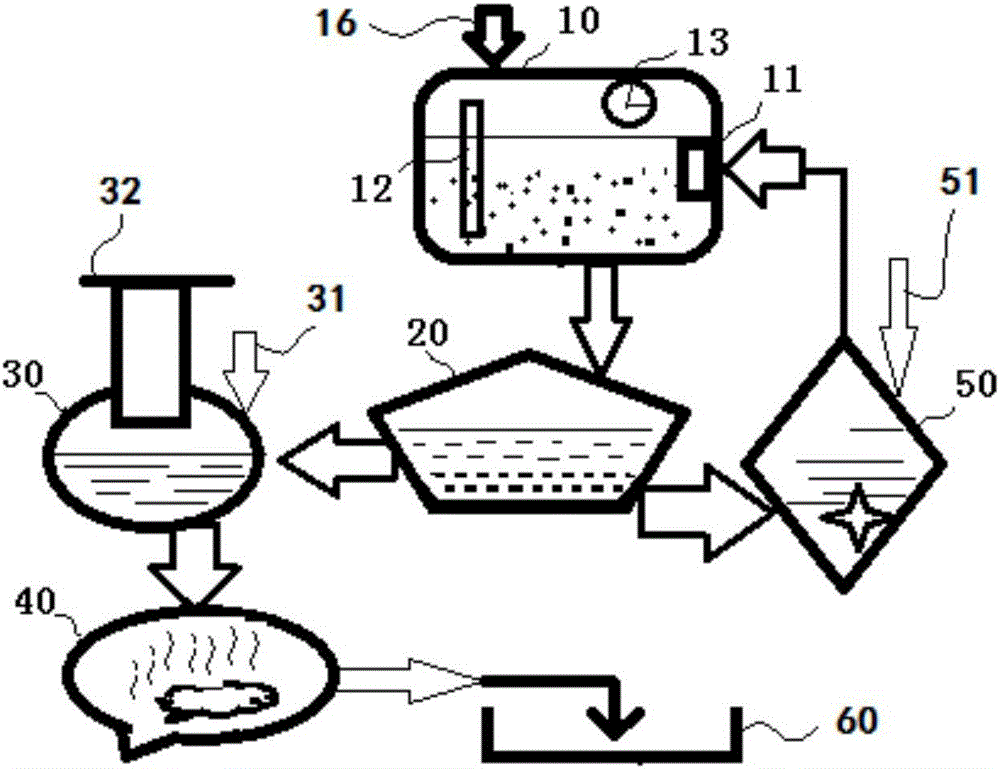

[0025] Example 1: Decompose scheelite concentrate with oxalic acid, decompose 10.0kg scheelite concentrate in a 50L reactor, the WO of scheelite concentrate 3 The content is 25%, the amount of oxalic acid added is 5.0kg, the decomposition temperature is 25°C, the reaction time is 14h, and the decomposition rate of tungsten in scheelite concentrate reaches 99.21%. The tungsten concentration in the filtered decomposition solution (tungsten oxalate solution) is 24.18g / L, the Ca concentration is 3.12g / L, the Zn concentration is 3.93g / L, the Mg concentration is 4.34g / L, and the Fe concentration is 4.50g / L , after extraction with N1923, the extraction rate of tungsten reaches 99.51%. After the loaded organic phase is back-extracted with ammonium chloride, the obtained ammonium tungstate solution can be evaporated and crystallized to obtain APT zero-grade product. After the decomposed slag is treated with sulfuric acid, the concentration of sulfuric acid is 2mol / L, and the treatment ...

Embodiment 2

[0026] Embodiment 2: oxalic acid decomposes scheelite concentrate, decomposes 10.0kg scheelite concentrate in 50L reactor, the WO of scheelite concentrate 3 The content is 45%, the amount of oxalic acid added is 8.0kg, the decomposition temperature is 55°C, the reaction time is 10h, and the decomposition rate of tungsten in scheelite concentrate reaches 99.54%. The tungsten concentration in the filtered decomposition liquid (tungsten oxalate solution) is 43.52g / L, the Ca concentration is 1.92g / L, the Zn concentration is 2.31g / L, the Mg concentration is 2.44g / L, and the Fe concentration is 2.68g / L After extraction with N1923, the extraction rate of tungsten reaches 99.55%. After the loaded organic phase is back-extracted with ammonium chloride, the obtained ammonium tungstate solution can be evaporated and crystallized to obtain APT zero-grade products. After the decomposed slag is treated with sulfuric acid, the concentration of sulfuric acid is 1mol / L, and the treatment time ...

Embodiment 3

[0027] Embodiment 3: oxalic acid decomposes scheelite concentrate, decomposes 10.0kg scheelite concentrate in 50L reactor, the WO of scheelite concentrate 3 The content is 50%, the amount of oxalic acid added is 9.0kg, the decomposition temperature is 55°C, the reaction time is 10h, and the decomposition rate of tungsten in scheelite concentrate reaches 99.54%. The tungsten concentration in the filtered decomposition solution (tungsten oxalate solution) is 48.36g / L, the Ca concentration is 2.10g / L, the Zn concentration is 2.61g / L, the Mg concentration is 2.94g / L, and the Fe concentration is 3.11g / L , after extraction with N1923, the extraction rate of tungsten reaches 99.57%. After the loaded organic phase is back-extracted with ammonium chloride, the obtained ammonium tungstate solution can be evaporated and crystallized to obtain APT zero-grade products. After the decomposed slag is treated with sulfuric acid, the concentration of sulfuric acid is 3mol / L, and the treatment t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com