Microcrystal silver powder with nano-silver surface structure, and preparation method thereof

A surface structure, nano-silver technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems that restrict the uniformity, consistency and complexity of surface coating modification, and achieve simple The effect of process control, narrow particle size distribution and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

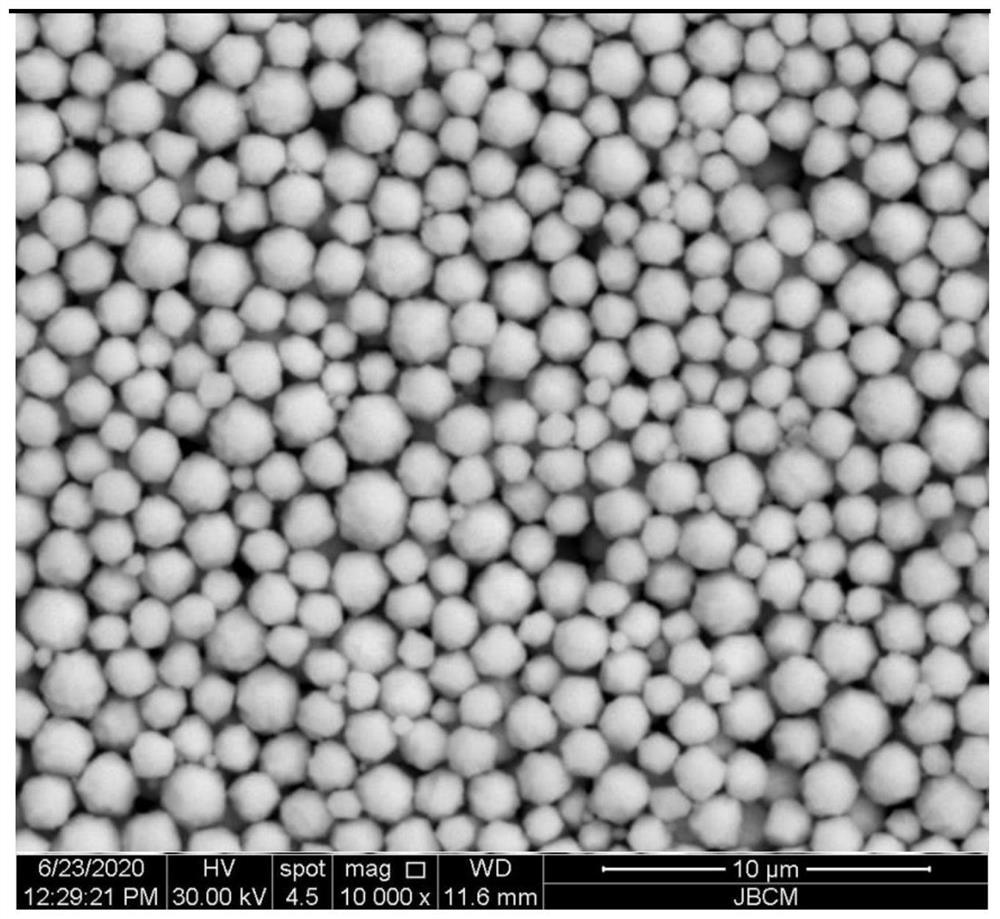

[0043] Embodiment 1 preparation particle diameter is the microcrystalline silver powder 1# with nano-silver surface structure of 0.5 micron

[0044] (1) Dosing

[0045] Silver nitrate solution A: Dissolve 500g of silver nitrate in 2750g of deionized water and stir to dissolve, and add 25g of concentrated nitric acid to prepare silver nitrate solution A. Wherein, the concentration of silver nitrate solution is about 1.0mol / L, and the consumption of concentrated nitric acid is 0.05 times of silver nitrate mass.

[0046] Dispersant solution B: Dissolve 250g of dispersant K30 in 3300g of deionized water and stir to dissolve to obtain dispersant solution B. Wherein the amount of dispersant is 0.5 times of the mass of silver nitrate in silver nitrate solution A; the amount of deionized water in dispersant solution B is 1.2 times of the amount of deionized water in silver nitrate solution A.

[0047] Ascorbic acid solution C: Dissolve 360g of ascorbic acid in 2750g of deionized wat...

Embodiment 2

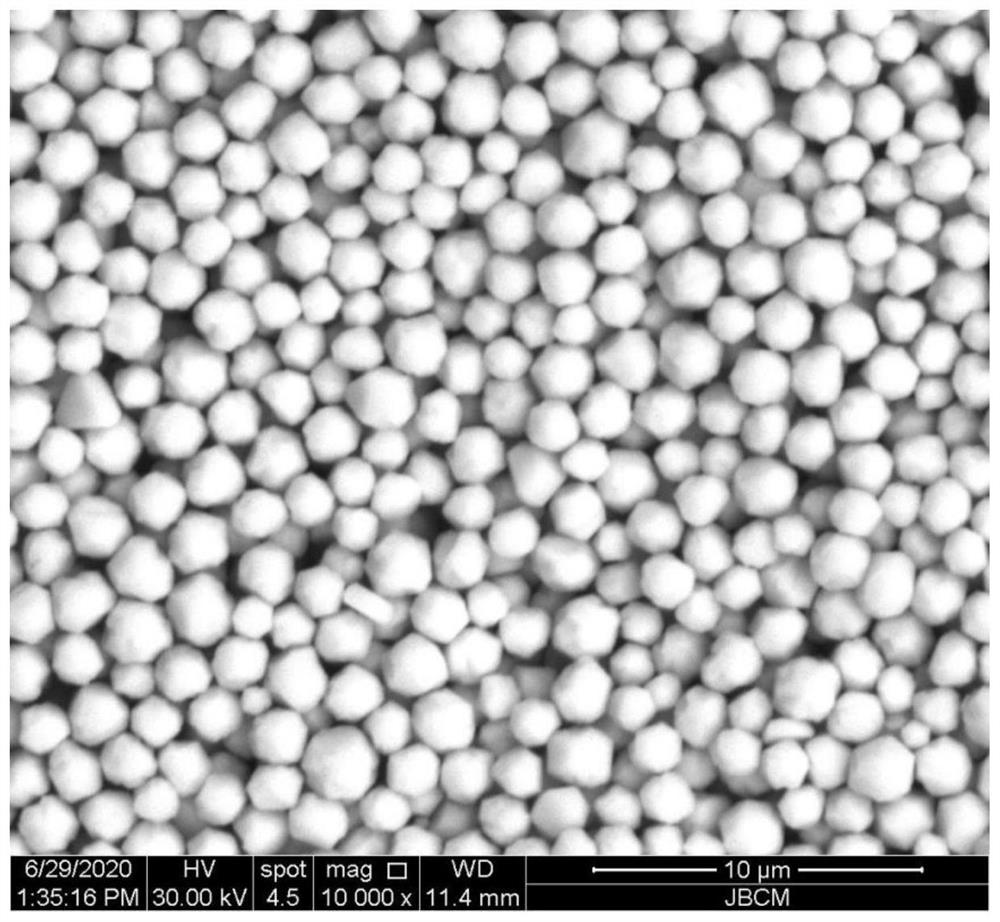

[0055] Embodiment 2 preparation particle diameter is the microcrystalline silver powder 2# with nano-silver surface structure of 1.0 micron

[0056] (1) Dosing

[0057] Silver nitrate solution A: Dissolve 750g of silver nitrate in 2750g of deionized water and stir to dissolve, and add 60g of concentrated nitric acid to prepare silver nitrate solution A. Wherein, the concentration of silver nitrate solution is about 1.5mol / L, and the consumption of concentrated nitric acid is 0.08 times of silver nitrate mass.

[0058] Dispersant solution B: Dissolve 300g of dispersant K30 in 3850g of deionized water and stir to dissolve to prepare dispersant solution B. Wherein the amount of dispersant is 0.4 times of silver nitrate quality in silver nitrate solution A; the amount of deionized water in dispersant solution B is 1.4 times of the amount of deionized water in silver nitrate solution A.

[0059] Ascorbic acid solution C: Dissolve 460g of ascorbic acid in 2750g of deionized water ...

Embodiment 3

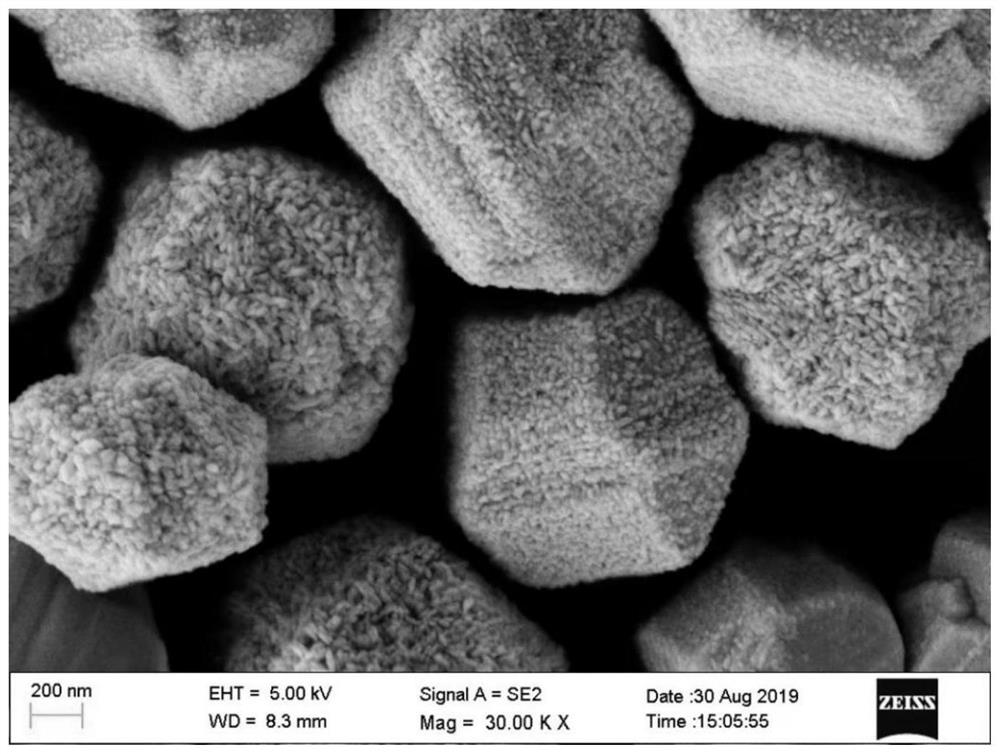

[0067] Embodiment 3 preparation particle diameter is the microcrystalline silver powder 3# with nano-silver surface structure of 2.0 microns

[0068] (1) Dosing

[0069] Silver nitrate solution A: Dissolve 750g of silver nitrate in 2750g of deionized water and stir to dissolve, and add 60g of concentrated nitric acid to prepare silver nitrate solution A. Wherein, the concentration of silver nitrate solution is about 1.5mol / L, and the consumption of concentrated nitric acid is 0.08 times of silver nitrate mass.

[0070] Dispersant solution B: Dissolve 265g of dispersant K30 in 3300g of deionized water and stir to dissolve to prepare dispersant solution B. Wherein the amount of dispersant is 0.35 times of the mass of silver nitrate in silver nitrate solution A; the amount of deionized water in dispersant solution B is 1.2 times of the amount of deionized water in silver nitrate solution A.

[0071] Ascorbic acid solution C: Dissolve 425g of ascorbic acid in 2750g of deionized ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com