Method for producing iron oxide red by utilizing titanium dioxide byproduct ferrous sulfate heptahydrate

A technology of ferrous sulfate and red iron oxide, applied in the direction of iron oxide, iron oxide/iron hydroxide, calcium/strontium/barium sulfate, etc. The problems of normal production of titanium dioxide plant and long time consumption of iron oxide red have achieved the effect of low cost, high cost and good product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

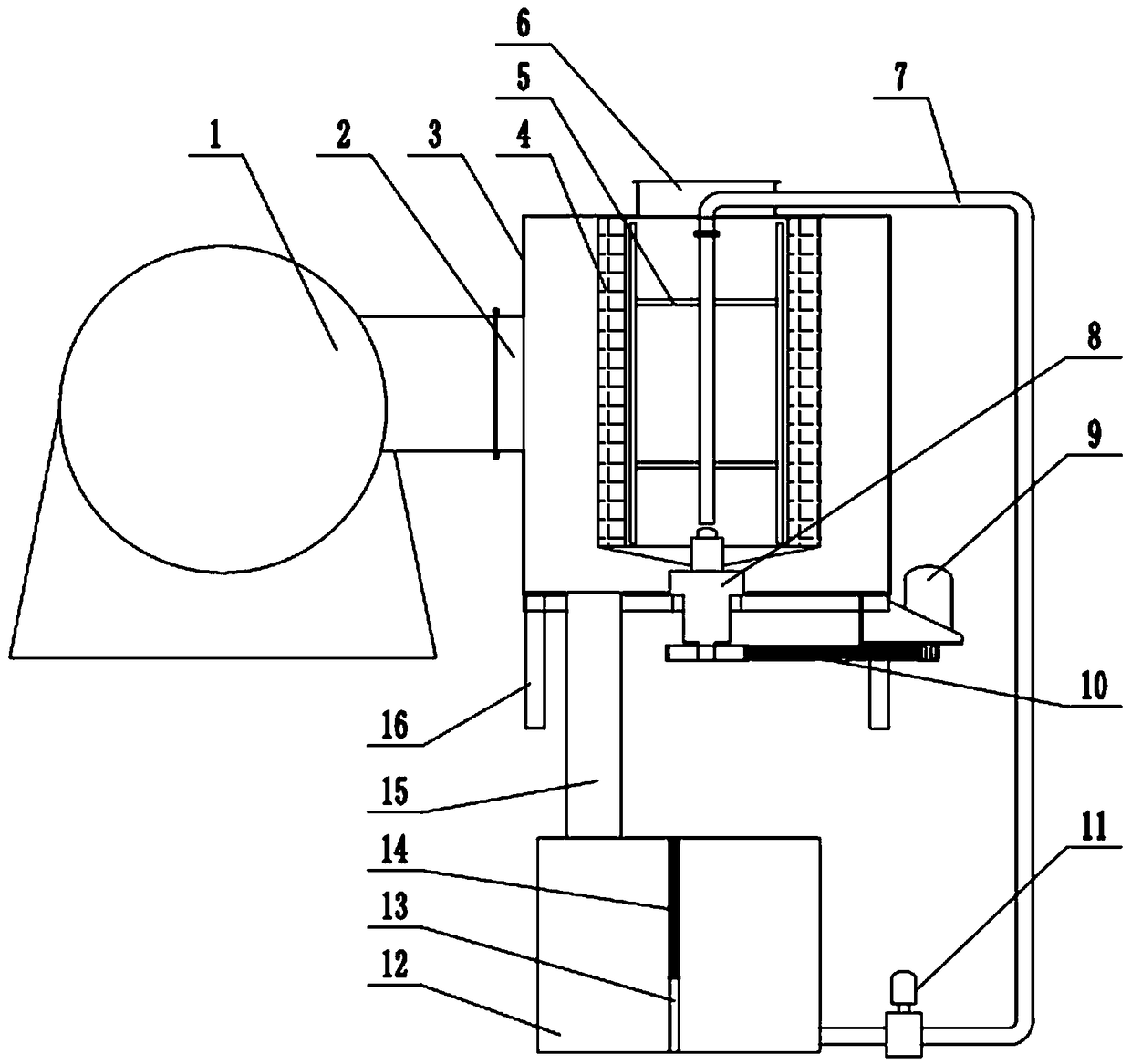

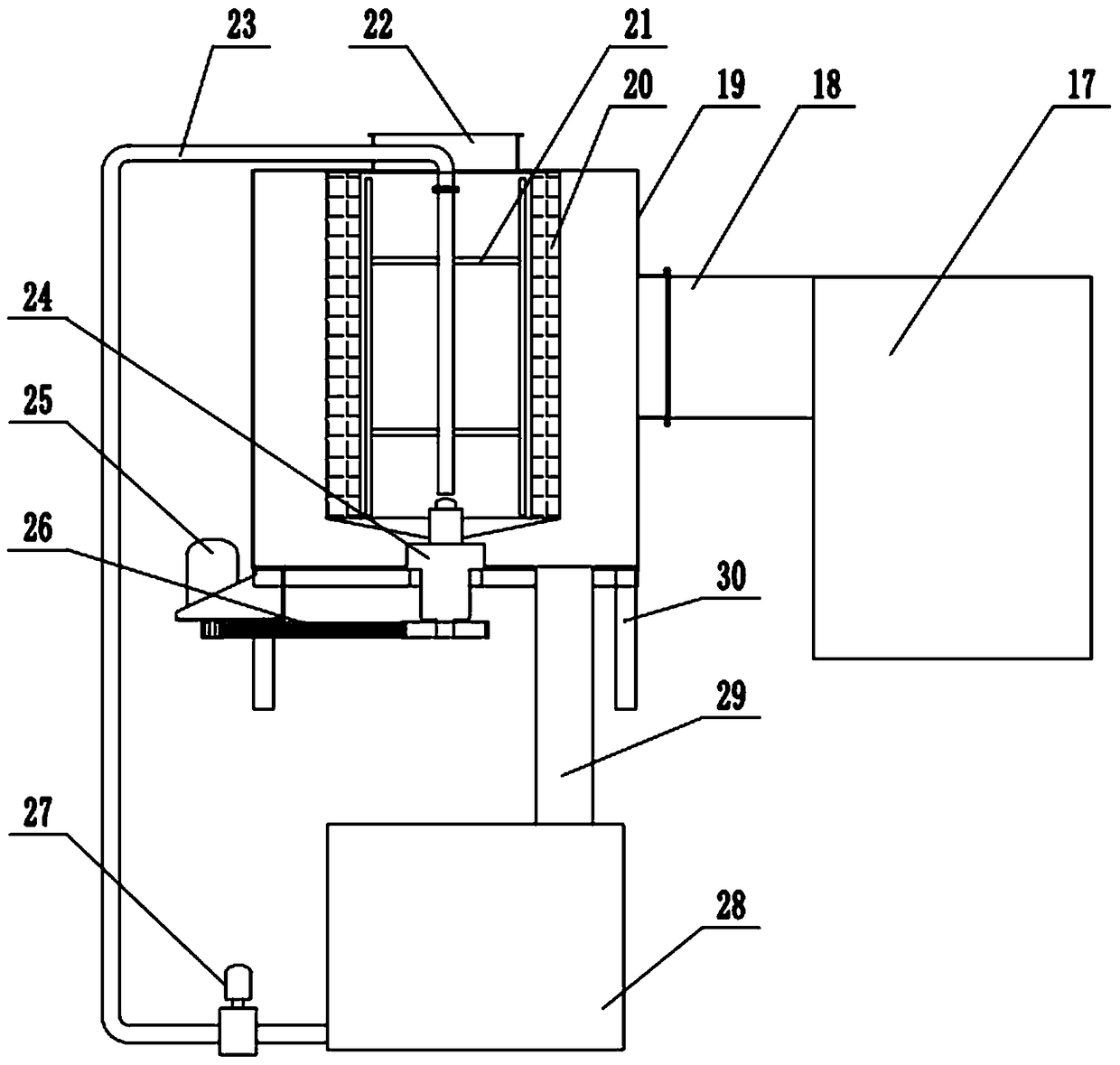

Image

Examples

Embodiment 1

[0039] Ferrous sulfate heptahydrate, a by-product of titanium dioxide, can be produced to obtain iron oxide red by the following production steps:

[0040] (1) Dissolve the by-product ferrous sulfate heptahydrate obtained from the production of titanium dioxide into an aqueous solution with a concentration of 8% by mass, and filter and take the liquid for later use;

[0041] (2) Pass the 8% aqueous solution into the mixing reactor, and pass through the ammonia gas, so that the 8% aqueous solution reacts with the ammonia gas to form (NH 4 ) 2 SO 4 and Fe(OH) 2 the mixture;

[0042] (3) Heat the mixed solution and pump it into the supergravity reactor, and let air in to make it react into Fe(OH) 3 and (NH 4 ) 2 SO 4 , and solid-liquid separation;

[0043] (4) Separate the Fe(OH) 3 Carry out water washing until the obtained liquid does not contain ammonium sulfate, and then wash the Fe(OH) 3 Carry out calcination, and finally carry out crushing and packaging to obtain t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com