A kind of self-wearing wood decoration material and its manufacturing method

A manufacturing method and technology of wear-resistant materials, applied in the direction of manufacturing tools, wood processing appliances, flat products, etc., can solve the problems of decorative paper mountain stripes, uneven distribution, loss of wear resistance, etc., and achieve random adjustment of wear resistance , simple process and equipment, good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

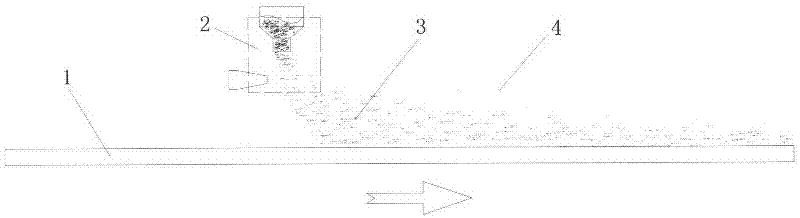

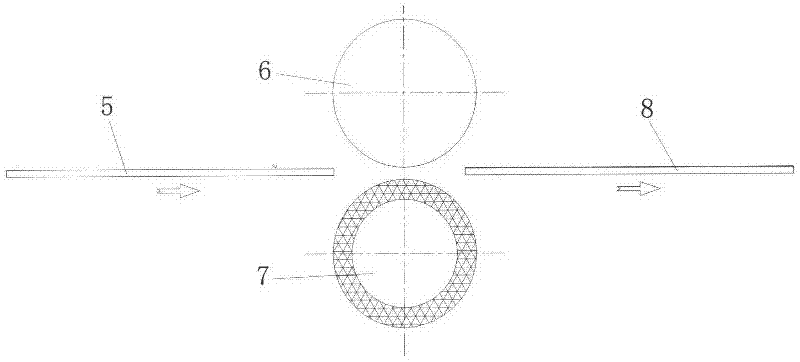

Embodiment 1

[0040] Use decorative paper as the base material, put it into impregnated resin (melamine formaldehyde resin and its modified resin, or urea-formaldehyde resin for impregnation), make it fully saturated, and then place it on the upper layer at 120°C, the middle layer at 100°C, and the lower layer at 80°C Carry out pre-drying in a special dryer, and the paper feeding speed is 2m / min, so that the decorative paper is slightly sticky when touched by hands. Then pave the selected wear-resistant materials (silicon dioxide, aluminum oxide, aluminum hydroxide and silicon carbide, etc.) with a particle size of more than 100 meshes on the pre-dried decorative paper through the air paving machine. The paving amount of wear-resistant material on the area is 20g / m 2 . Then pass the decorative paper paved with wear-resistant materials through a pair of round rollers for densification parallel up and down, and compact the wear-resistant particles with polishing rollers to make them firmly a...

Embodiment 2

[0043] Choose high-tech wood as the substrate, put it into impregnated resin (melamine formaldehyde resin and its modified resin, or urea-formaldehyde resin for impregnation), make it fully saturated, and then place it at an inlet temperature of 120°C, a middle temperature of 100°C, and an outlet temperature of 80°C. Pre-drying in a drying machine at ℃, the drying speed is 1.5m / min, so that the technical wood is slightly sticky when touched. Then pave the selected wear-resistant materials (silicon dioxide, aluminum oxide, aluminum hydroxide and silicon carbide, etc.) with a particle size of more than 300 meshes on the pre-dried technical wood through an air-flow paving machine. The paving amount of wear-resistant material on the area is 15g / m 2 . Then pass the high-tech wood paved with wear-resistant materials through a pair of round rollers for densification that are parallel up and down, and compact the wear-resistant particles with polishing rollers to make them firmly adh...

Embodiment 3

[0046] Choose sliced veneer as the substrate, put it into the impregnating resin (melamine formaldehyde resin and its modified resin, or urea-formaldehyde resin for impregnation), make it fully saturated, and then place it at an inlet temperature of 100°C, a middle temperature of 90°C, and an outlet temperature of 100°C. Pre-dry in a dryer at 80°C, with a drying speed of 1.0m / min, so that the sliced veneer is slightly sticky when touched by hand. Then pave the selected wear-resistant materials (silicon dioxide, aluminum oxide, aluminum hydroxide and silicon carbide, etc.) with a particle size of more than 200 meshes on the pre-dried sliced veneer through the air paving machine, The paving amount of wear-resistant material per unit area is 10g / m 2 . Then pass the planed veneer paved with wear-resistant materials through a pair of round rollers for densification that are parallel up and down, and compact the wear-resistant particles with polishing rollers to make them fir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com