Polysiloxane dihydric alcohol, thermoplastic organic silicon polyurethane elastomer, cross-linked polyurethane elastomer and application of polysiloxane dihydric alcohol, thermoplastic organic silicon polyurethane elastomer and cross-linked polyurethane elastomer

A polyurethane elastomer and polysiloxane technology, applied in the field of polyol and elastomer materials, can solve the problems of cumbersome and complicated process, many steps, and difficult implementation, and achieve simple equipment and process, low cost, and good comprehensive performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

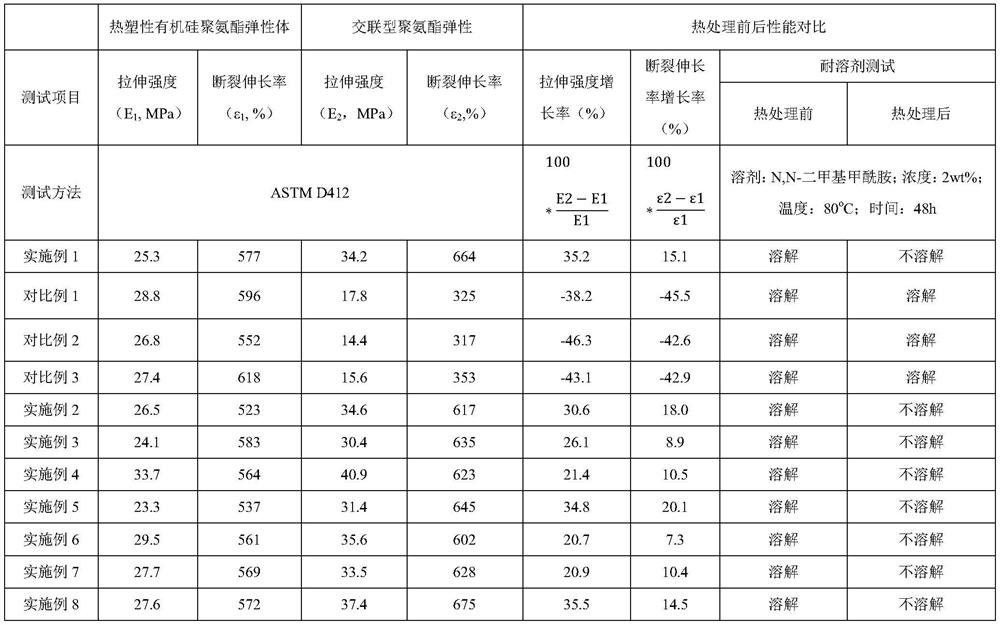

Embodiment 1

[0034]Raw materials for preparing thermoplastic organosilicon polyurethane elastomer, calculated on a total weight of 100 parts, including:

[0035] 1) diisocyanate: diphenylmethane diisocyanate, 35 parts;

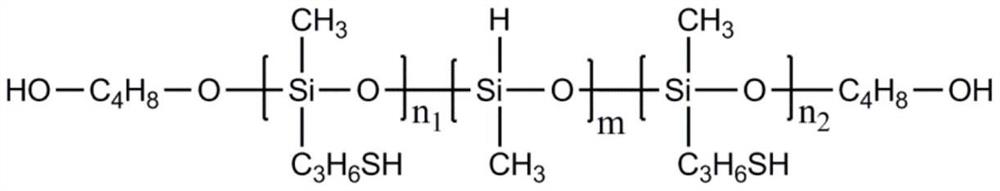

[0036] 2) polysiloxane diol: 10 parts, its preparation method comprises the following steps:

[0037] Step I: 80 parts by weight of 2,4,6,8-tetramethylcyclotetrasiloxane (CAS NO. 2370-88-9), 20 parts by weight of end-capping agent deionized water, 40 parts by weight of Isopropanol solvent and 0.2 parts by weight of catalyst NaOH were added to the reaction kettle, and the temperature was raised to 70 ° C, and the reaction was carried out for 2 hours. After sampling and measuring the hydroxyl value of 133 mgKOH / g, phosphoric acid was added to neutralize the system until the system was neutral. - Extract the solvent under the condition of 0.1MPa to obtain the hydrogen-containing silicone oil end-capped with silanols;

[0038] Step II: add 0.8 mole parts of 3-mercaptopropylm...

Embodiment 2

[0081] Raw materials for preparing thermoplastic organosilicon polyurethane elastomer, calculated on a total weight of 100 parts, including:

[0082] 1) diisocyanate: hexamethylene diisocyanate, 45 parts;

[0083] 2) polysiloxane diol: 5 parts, and its preparation method comprises the following steps:

[0084] Step I: 90 parts by weight of 2,4,6,8-tetramethylcyclotetrasiloxane (CAS NO. 2370-88-9), 10 parts by weight of end-capping agent deionized water, 20 parts by weight of Isopropanol solvent and 0.4 parts by weight of catalyst NaOH were added to the reactor, the temperature was raised to 60°C, and the reaction was carried out for 3 hours. After sampling and measuring the hydroxyl value of 187 mgKOH / g, phosphoric acid was added to neutralize the system until the system was neutral. - Extract the solvent under the condition of 0.1MPa to obtain the hydrogen-containing silicone oil end-capped with silanols;

[0085] Step II: add 0.6 mole part of 3-mercaptopropyl methyldimetho...

Embodiment 3

[0094] Raw materials for preparing thermoplastic organosilicon polyurethane elastomer, calculated on a total weight of 100 parts, including:

[0095] 1) Diisocyanate: 1,4-cyclohexane diisocyanate, 25 parts;

[0096] 2) polysiloxane diol: 2 parts, and its preparation method comprises the following steps:

[0097] Step I: 70 parts by weight of 2,4,6,8-tetramethylcyclotetrasiloxane (CAS NO. 2370-88-9), 30 parts by weight of end-capping agent deionized water, 30 parts by weight of Isopropanol solvent and 0.5 weight part of catalyst NaOH were added to the reaction kettle, and the temperature was raised to 80°C, and the reaction was carried out for 1 hour. After sampling and measuring the hydroxyl value of 311 mgKOH / g, phosphoric acid was added to neutralize the system until the system was neutral. - Extract the solvent under the condition of 0.1MPa to obtain the hydrogen-containing silicone oil end-capped with silanols;

[0098] Step II: add 0.5 mole part of 3-mercaptopropyl meth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Number average molecular weight | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com