Heating furnace radiation area collecting pipe surface high temperature corrosion resistant coating and preparation method thereof

A technology for corroding coatings and radiation areas, applied in coatings, metal material coating processes, fusion spraying, etc., can solve the problems of staying in the laboratory, single type of coating, limited protective effect, etc., and achieve equipment and process Simplicity, improved bonding strength, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

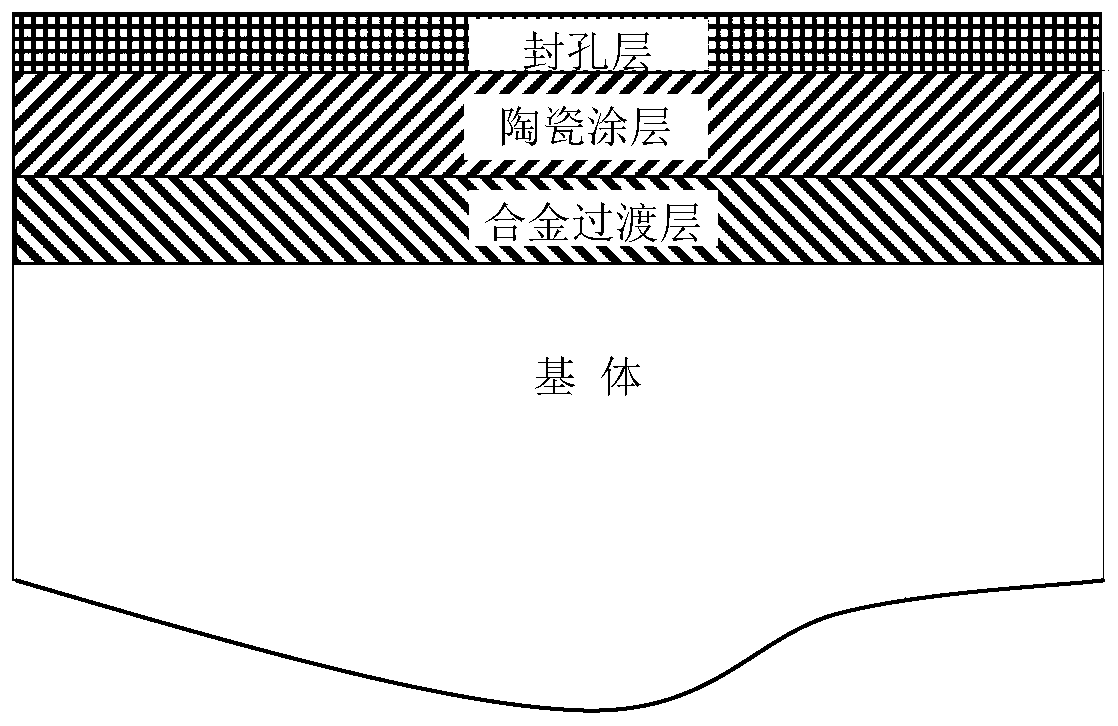

[0031] A heat-resistant steel sheet with a thickness of 3 mm is selected as the base material. The thickness of the NiCrAlY alloy transition layer on the base is 30 μm, and the thickness of the YSZ ceramic coating is 80 μm. The specific preparation method is as follows:

[0032] 1. Clean the substrate, and use 60-mesh brown corundum sand for surface blasting pretreatment to make the roughness meet the spraying requirements and improve the bonding strength between the coating and the substrate.

[0033]2. Supersonic flame spraying is used to prepare the alloy coating on the surface of the substrate. The parameters used are: the pressures of oxygen, propane gas and compressed air are 1.8MPa, 0.4MPa and 0.6MPa respectively, and the flow rates are 550slpm, 60slpm and 400slpm respectively. The powder feeding gas pressure is 0.6MPa, the flow rate is 10-20slpm, the powder feeding rate is 60g / min, and the spraying distance is 200mm.

[0034] 3. Prepare a ceramic coating on the surface...

Embodiment 2

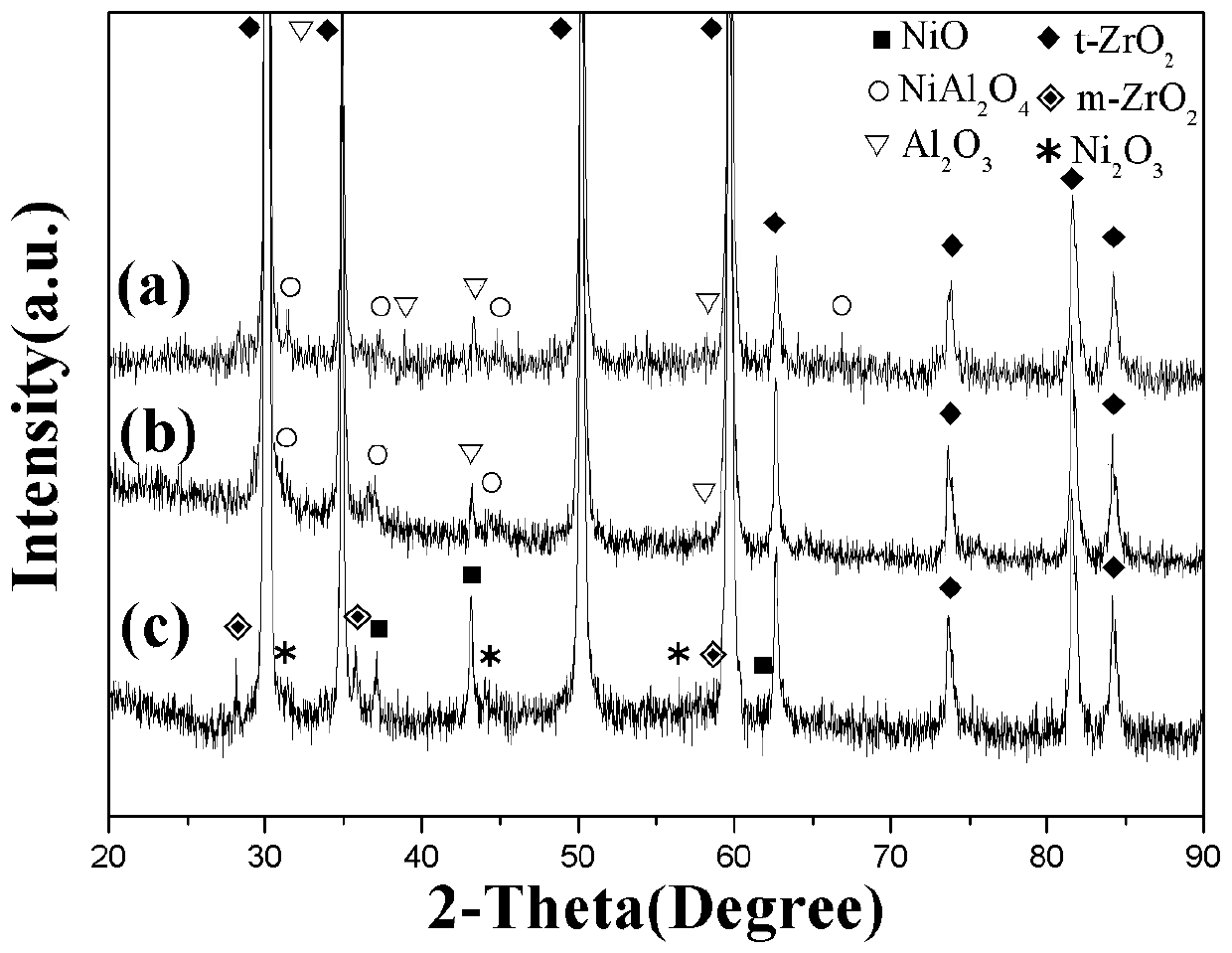

[0038] In this example, the amount of Al added in the sealing agent was changed to 0.3 wt%, and other preparation conditions were exactly the same as those in Example 1. Using a muffle furnace to test the static oxidation performance of the coating at high temperature, when the temperature is 1000 ° C, the coating sample has no obvious peeling off, cracking, perforation and other phenomena within 50 hours, indicating that the coating has good high temperature oxidation resistance .

Embodiment 3

[0040] In this example, the Al in the sealing agent is changed to a mixture of Al and Ni, the mixing ratio is Al:Ni=3:2, and other preparation conditions are exactly the same as in Example 1. Using a muffle furnace to test the static oxidation performance of the coating at high temperature, when the temperature is 1000 ° C, the coating sample has no obvious peeling off, cracking, perforation and other phenomena within 50 hours, indicating that the coating has good high temperature oxidation resistance .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com